Software fills that space between what the ‘thing’ actually does and what you ideally want it to do…

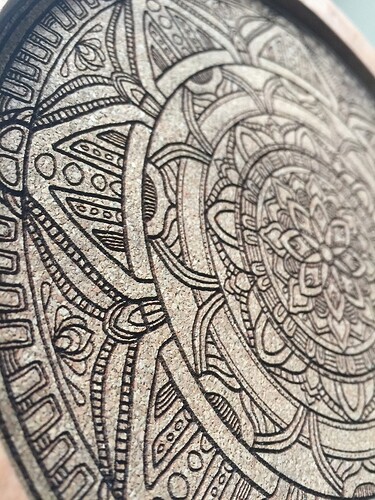

I used the cnc to cut the wood base and use the laser to cut the cork for the bottom

Looks great, I like the glass door.

The cork engraved beautifully, very nice product! Walnut(?) color is perfect compliment.

Easy to dial in the speed/power settings for the engrave?

I am quite late to the thread, but did the laser come with Cooling, Air Assist, and Ventilation included in the pricetag?

There are other things comparable to the Glowforge in many ways. The only things I haven’t really seen anywhere else is removing the need for alignment procedures, and the drawing to cut workflow. Well, and all of the nice things tossed together with portability.

For me, I can do all of the setup on a larger laser, but I want the Glowforge for using with school kids, and of course taking to those kids.

The laser can still cut quite nicely past the focal point. Not AS nicely… but it can cut, and especially burn. I had thought that the focal lens would cause enough divergence after the focal plane that I could avoid using a honeycomb by having the table surface far enough down. So I pointed the laser through a hole in the table at the floor 3 feet below. At full power it made a scorch mark in about 10 seconds.

Yes… this is rather safe if you are paying attention. But most of the scary laser fires are from unattended cuts, not from momentary fluctuations.

Whoa, that’s unexpected! A few questions come to mind, if you don’t mind… What kind of floor? How powerful of a laser? (I’m guessing CO2.) What focal length was the lens? How big was the mark?

60W CO2 laser. Just picked up some images to answer as well as possible. My memory of how long until we got a scorch may be off, since my memory of distance was as well. Only 2 feet out from the table.

The normal kerf at the table surface where we had the ventilation hole to burn through:

The gap we shot through:

And the resulting scorch mark:

So a beam width of about 1cm just below our focal depth became a 20cm scorch 2 feet later (with absolutely nothing between focusing lens and that spot at the time).

Our lens is a 75mm focal length 20mm GaAs lens. (looked up our original BOM for that one, I would have said ZnSe if I went from memory)

Put a bag of popcorn kernels down there and make yourself a nice snack next time

Challenge accepted

Diameter of scorch mark, 20 millimeters?

I’m also on the fence. The prices for Chinese lasers have dropped dramatically lately, and many vendors shipping from California saves the Import drama. So Now i waver on my decision.

All the talk about the “Software”, “Camera” and “Autofocus” have been these big advantages in the marketing of the GF, yet no one has seen them work. Nor will these elements have been “put through the wringer” enough to be a really awesome first Rev. and be really pissed when the much improved Rev. 2 is released. (Shapeoko2 buyer here!)

So, yeah I waver.

I’ve also worked with several laser cutters before. Paper bursts into flames, it happens. There’s a blower fan venting the fumes, an air inlet for air assist. None of this on the GF makes me wonder what magical Koolaid I was drinking when I dropped my $5k. This fantasy HEPA will really keep my kitchen safe when cutting 67 acrylic name plates? (no, it won’t be in my kitchen. I could care less about the looks)

Tell me I’m crazy. Tell me that a bigger work area and a more powerful laser for the same $ is LAME. Tell me I need some sexy silver-lined laser appliance in my kitchen. Tell me to just forget about 3/4" plywood, (my favorite material du jour) and anything thicker. Tell me that Rev. 1 products are always flawless and never guinea piggish. Tell me GF MUST spend shit-tons of money on marketing, bringing new backers, and analyzing Google Marketing, rather than show some basic deliverables.

That’s what’s been going through my head today. I could be tinkering, perfecting a big-ass laser NOW for less than a GF.

I’m happy I got this one and I’m excited about the glowforge still. After seeing one in person and seeing the camera function was pretty cool. If say get the China laser if you can swing it and keep your preorder. If the first ones are great then stick with the order but if they suck then just request a refund. But from the looks of them in person , they look amazing

Oops. Yeah. That is why I did pictures >< I can screw up even breathing some days…

Not sure whether you are looking for validation or still thinking. But just for clarification. The Basic GF does have air assist and air purge (exhaust fans). Can’t speak to the effectiveness of their methods until we get our hands on a production unit.

But where is the"air assist"coming from? If it’s onboard, in a desktop machine, it will need a small compressor pump. Small compressors are notoriously the bane many “miniaturized” tool (small plasma cutters). In my experience, anything generating air is either LOUD and rattles the unit across the floor, or big and oil driven. (Given the smallish Jun-Air is around $2600, is still bigger than the GF).

Thanks for the Clarification, but until we actually DO see a production unit, I feel wary.

Yeah, I know they LOOK amazing, but…

“what’s in the box…???”

The air compressor I run my 60w off is pretty tiny and it works great, I even need a regulator to dial it down when cutting paper. I’m not concerned about the very basics of the machine such as the air assist, I’m sure they figured that out.

There is no risk since you can just get a refund from glowforge, not concerned because of that.

Fish tank compressors that run 24/7 are quiet…don’t need much psi to run air assist. I do airbrush and use 10-20 psi from a small compressor just fine.

The thing you have in your fishtank- that’s an ‘air pump’ not the required pressure for air assist, and an airbrush compressor is still considerably larger than allowable in the standard Chinese laser, much less the minimalist desktop G’Forge. Not to mention, dampening that vibration IN the unit would be a challenge with flyover optics.

Don’t get me started on the water cooling, whole 'nother animal. If it’s internal (supposedly is) it needs to be serviceable.