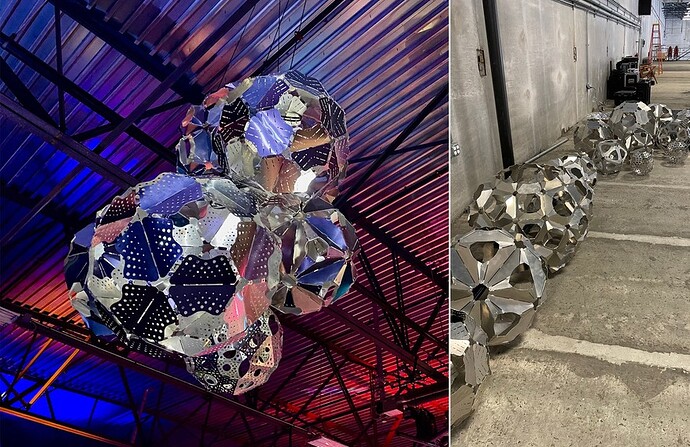

So after months of prototyping in paper and cardboard on my GF, Gendry, I was invited to do a lighting installation for a big gala fundraiser in a helicopter hanger here in Chicago. I took nine of the successful paper designs and modified them to work in a more durable aluminum variation, then had them cut by SendCutSend in Reno, NV. Shipped here to IL and assembled in my garage. Went live last night, first photos are here, along with some older ones showing early paper models.

This is great. It must be so satisfying to see the final product in aluminum and illuminated after the hours of paper and cardboard work.

These are truly wonderful. Must have been so exciting for you…to be asked to do it in the first place and then see your final work literally, in lights. Congratulations!

Final was awesome.

Curious though. What happens to them now?

Made a great display!

Okay, awesome! Vision to reality through rapid prototyping.

Visually satisfying; what a great design!

Wow!!

Not sure yet — looks like we’ll have quite the holiday display in our front yard.

Really nice! I have been looking at that but when they charge by the linear inch for the cuts, I have had to not go there. Your designs are much more simple that way. I presume the ones with little holes come that way and not a part of the cutting price?

Great designs! They look great in paper and aluminum!

Those look awesome!

Wow, you should be a designer for IKEA!!

Those are fabulous!

Wow! These are magnificent. Congrats on such a great installation!

I’ve wanted to try SendCutSend for metal sculptures. Are you using “perforations” to create folds and then bolts or rivets to join pieces together? Did you do the folding by hand?

Whoa. That is EPIC! What a cool opportunity, and you nailed it! Hope it leads to more. Way to go!

Great work! I do believe I’ve played roller derby in that helicopter hangar! It’s a fun venue!

Awesome work. Great design, to see the process start to finish, so rewarding I’m sure.

Hi Toby – regarding SCS, I tried a variety of perforations for folding the metal that would match what I’d been doing at home in paper. Most of these go beyond just perforation to the point that 80% of the folded edge is cut out, which shows the lights inside really well. I’ve been riveting everything since I bought a rivet gun this spring, much faster than bolting. All hand folded, though I set up a little jig in the garage for consistency.

Thank you, that’s very helpful!