This is an interesting little item–looks like the resolution is crude, but it’s a promising idea for jewelry artisans and folks who can prototype in soft metal.

I couldn’t afford one but just looking at it, I’m sure I’ll end up losing hours just watching youtube videos about it in the future. Neat.

Wow, VERY interesting. I couldn’t determine if it was usable also with PMC (precious metal clay), or only the bronze mixes they were selling on the website. If it could, I would be a lot more interested.

That is impressive. The amount of work that has gone into that system is immense. Clay extruders are not easy to build.

I would assume that if you can get the consistency correct, you should be able to use pretty much any material that is extruded in a slurry or paste. The bronze mix on the website is probably what they are using for testing and development and that is what works the best so far. Anything else you can probably use but it will most likely be at your own risk.

My understanding is that there are metal clay filaments for delta 3D printers, so the value of this one seems to me to be more in the easy of finishing sculpting of the unfired clay pieces. And, like @cynd11, I’d be WAY more interested if there were other metals available.

A little research brought me to the manufacturer of the BRONZclay:

https://www.riogrande.com/category/metal-clay-glass-enamels-and-resins/metal-clay

I assume that by adding water you could manipulate the consistency of the silver or gold clays to meet the requirements of the printer.

The other way you can experiment is to change the size of the extrusion nozzle. You will need to add more water I assume or really slow down the printing speed. This would allow you to print more detail, though from the pictures, I don’t know that it would be an issue.

There are also steel nozzles available that may provide better control or durability than the plastic ones.

I would assume the same, but it is curious that they don’t mention such an option, which would be of greatest interest to jewelers who seem to be their target market.

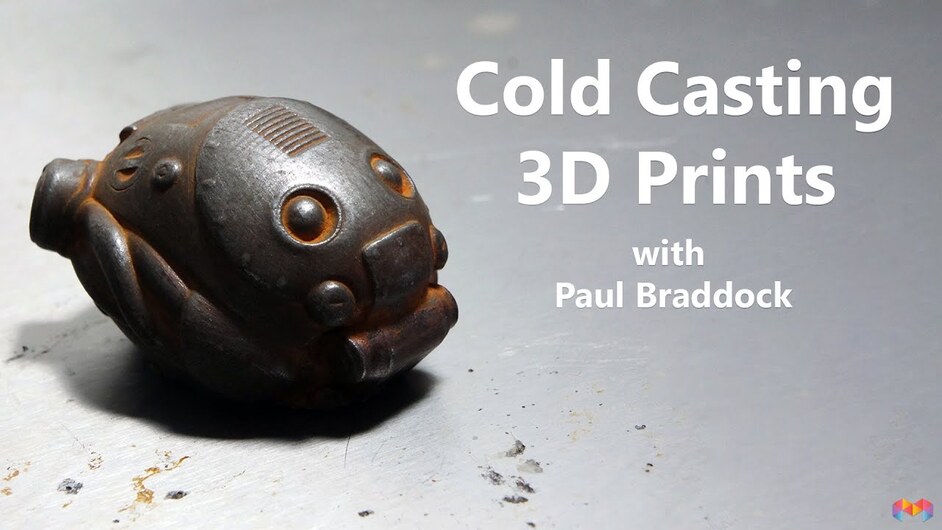

Its obviously not the same and has a couple of extra steps, but this is what Im looking to do when I get my 3d printer:

Hes using iron powder, but it can be swapped for something else if youre looking for a different metallic effect.

Cool tutorial! It’s a slightly different situation but this method is certainly useful for some things. I love how the final product was even attractive to magnets!

This is fantastic. I’d love to get an SLA printer just to be able to achieve that kind of resolution.

@vagozs Very cool Tutorial! Eventually I would love to do some things like this. Eventually I will get a 3D printer. Most likely just a simple one to start. @morganstanfield That looks like a really cool machine. Thanks for sharing!

I have zero experience with 3D printers. Does anyone have an opinion on a good printer for $2,000 or less? I hate to go cheap but I also hate to spend big bucks and not enjoy 3D printing or not being good at it and wasting the money.

I’ve heard very good things about the Makergear M2: http://www.makergear.com/products/m2?gclid=Cj0KEQjwqMHABRDVl6_hqKGDyNIBEiQAN-O9hNleQQFCbWJng87SouDlrKecTjDXCGAzWMjvT27PDAAaAhoz8P8HAQ

You can currently get it fully built or in kit form for a nice discount if you are handy with a screw driver.

I’ve been rocking the Makerbot Replicator 2 for quite a while and it’s been very good to me, but I’d very much like to trade it up for one of these babies one day.

This is the one I`m going to have: https://www.kickstarter.com/projects/1403065126/trinus-the-affordable-all-metal-3d-printer

The print area is smaller than the Makergear, but the price is much smaller at the same time.

This is their preorder page: https://trinus-the-affordable-all-metal-3d-printer.backerkit.com/hosted_preorders/57833

It should be shipping in December, so it`d be an awesome Christmas if I received both that and the Glowforge.

I have a Printrbot Play. It’s $399 and as bare-bones as you can get, but having used it side by side with much more expensive 3D printers, I can say that it’s a great way to figure out if you like it or not. It’s very similar, just lacking bigger size, multiple heads, etc.

(I believe it uses open source software from one of its more expensive competitors, so you get to see what that’s about too.)

Some of you should be getting it in December with all the quirks and add-ons I"m hoping for January with December being a nice surprise if it happens

If the metal clay is anything like regular clay, adding anything to change the consistency will also change the shrinkage when dried and fired. Which might work out OK.

I have a couple of printrbots (one wood, one sheet metal) that I like pretty well, but I’m not sure I want clay anywhere near the threaded rods… I’ve been rehabbing an old Shapeoko and thinking about putting a clay/paste/etc extruder on that, though. There are plenty of designs for clay extruders out there; it seems mostly a question of whether you want something that turnkey or something you have to know in detail how it works (and how to tune it).

I admit I am biased. My suggested printer is the CEL Robox. This printer has mediocre reviews on Amazon. My experience with the printer is much different. I run four of them and use them to provide 3D printing services through 3D Hubs. The number of prints I have fail due to a printer problem is about 1 in 100. I cancelled my filament recycling machine because I don’t generate enough scrap to justify the purchase of the recycler.

The printer is designed to be easy to use and while the build volume is smaller than some, it prints 95% of what my customers ask for. I have had several customers express disbelief that their parts had been 3D printed due to the consistent quality of the printer.

The printer uses a dual nozzle design to allow you to print draft prints or fine detail prints without needing to change hot ends. There is also the option to do a combined profile where you can use both nozzles in the same print, speeding up your print time by up to twice as fast, due to the ability to not print infill in every layer.

The filament flow is monitored from reel to print head so that if there are issues with filament movement the printer will automatically stop the print, attempt to fix the flow issue, and resume. If it is unable to fix it, it will pause until you can sort the problem and then will continue. This also reduces failed prints due to the material running out since it will stop the print if it runs out of material and wait until you load more material.

Dual materials are an option at extra cost.

The printer also comes with a 1 year warranty in the US, something that is hard to find. All US service is done in Arizona and the response time for support is usually within 30 minutes.

I run the support center and have been using the printers for about 2.5 years. In that time, other than consumables like the print head and extruder, I haven’t had to replace a part that wasn’t covered under the warranty.

I appreciate the input, it helps a lot because just about every printer I have found has a split on reviews. Nice to hear from someone who had used one as much as you.

I just donated my Makerbot Replicator 2X to our MakerSpace. ![]() Good enough machine with dual extruders and heated bed with a good build size. I think the M2 (also have) or the Utilmakers are easier to use and more reliable once you get them dialed in.

Good enough machine with dual extruders and heated bed with a good build size. I think the M2 (also have) or the Utilmakers are easier to use and more reliable once you get them dialed in.

The one accessory you should get for any of them is a BuildTak bed plate cover. Way better than kapton tape or glass with hairspray or painters tape for good adhesion of the base layers.