I was feeling left out of the polyhedra thing and, kind of wanted to make some small models. I didn’t feel like I had a lot of free studio time to mess with it, though. So, I spent a bunch of time coming up with a completely different way of making small polyhedra …

These are essentially paper craft polyhedra with an outer layer attached.

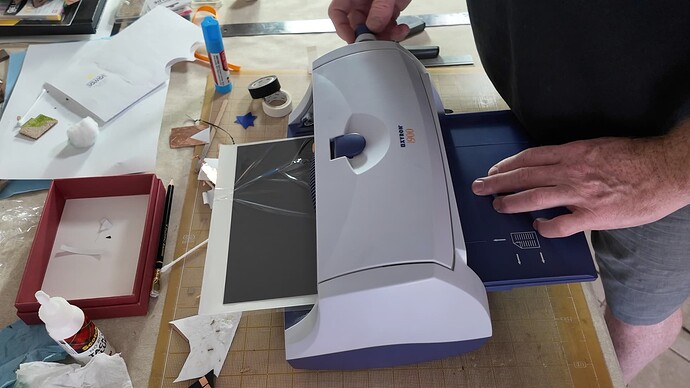

The basic approach is to laminate something to a base layer of heavy card stock. I’m using some 380gsm stock in black or white for the base. I have a cold laminator that will apply a permanent adhesive evenly to one side of the card stock but, it could likely be done with spray glue or even brushed on.

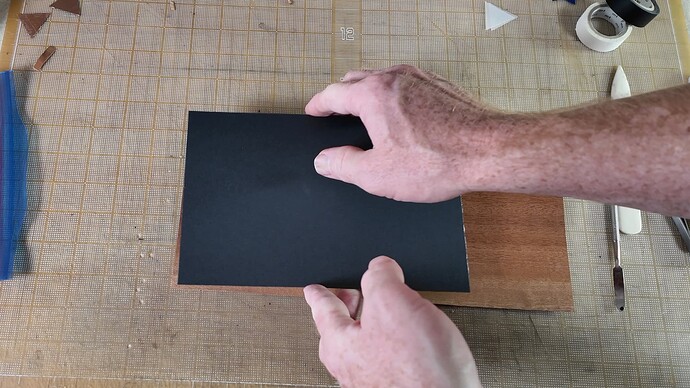

For the “something” I laminate to it, I have used other card stock, wood veneer, shell veneer, cork and, fabric. I’m sure all sorts of other things would work, too.

Next, the laminate goes into the laser where I cut through just the outer layer and a little bit of the base layer for all of the fold lines (between faces) and, cut the outline. I test each combination of materials (each pair of materials for variable materials like wood veneer) to find optimal settings.

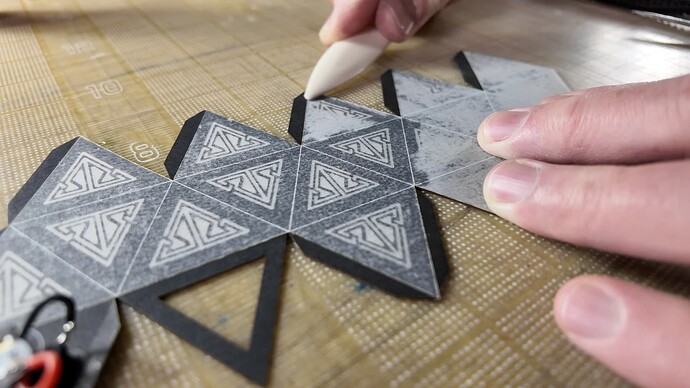

After it comes out of the laser, I delaminate the outer layer on the tabs.

Then, break all the folds.

I found some fast-drying PVA-style glue [1] that sets up in about a minute (and gets more solid over a longer interval). That helps make the assembly less tedious.

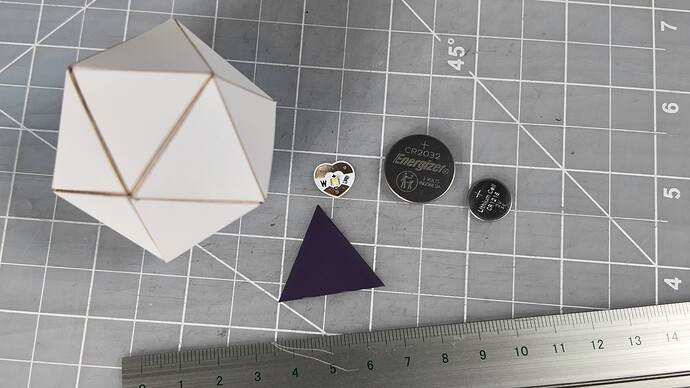

One issue with paper craft polyhedra is that it is difficult to stick the final connecting tabs well because you can’t get inside to apply pressure to both sides. I resolved this by cutting a hole in the final face, leaving just a frame, so that I can get a tool inside to hold the last joints. Delaminating the frame like I do for the tabs makes it possible to put a solid single-layer face piece over the hole to hide it.

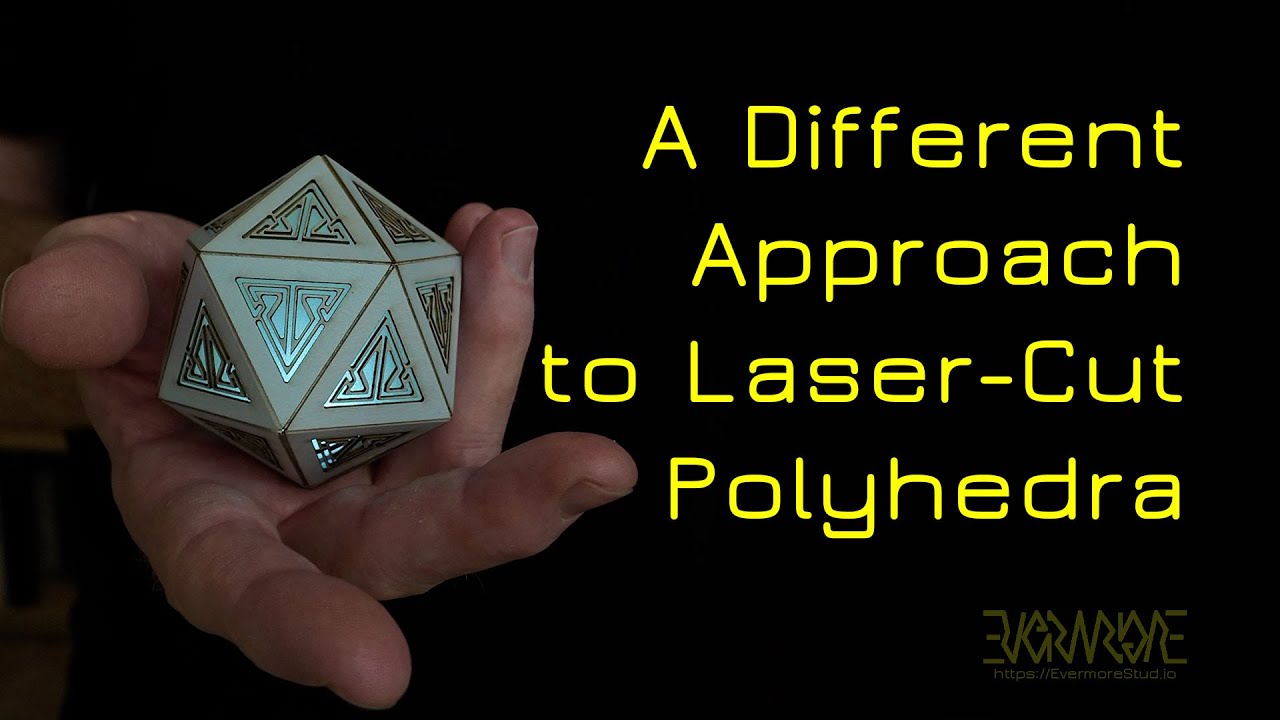

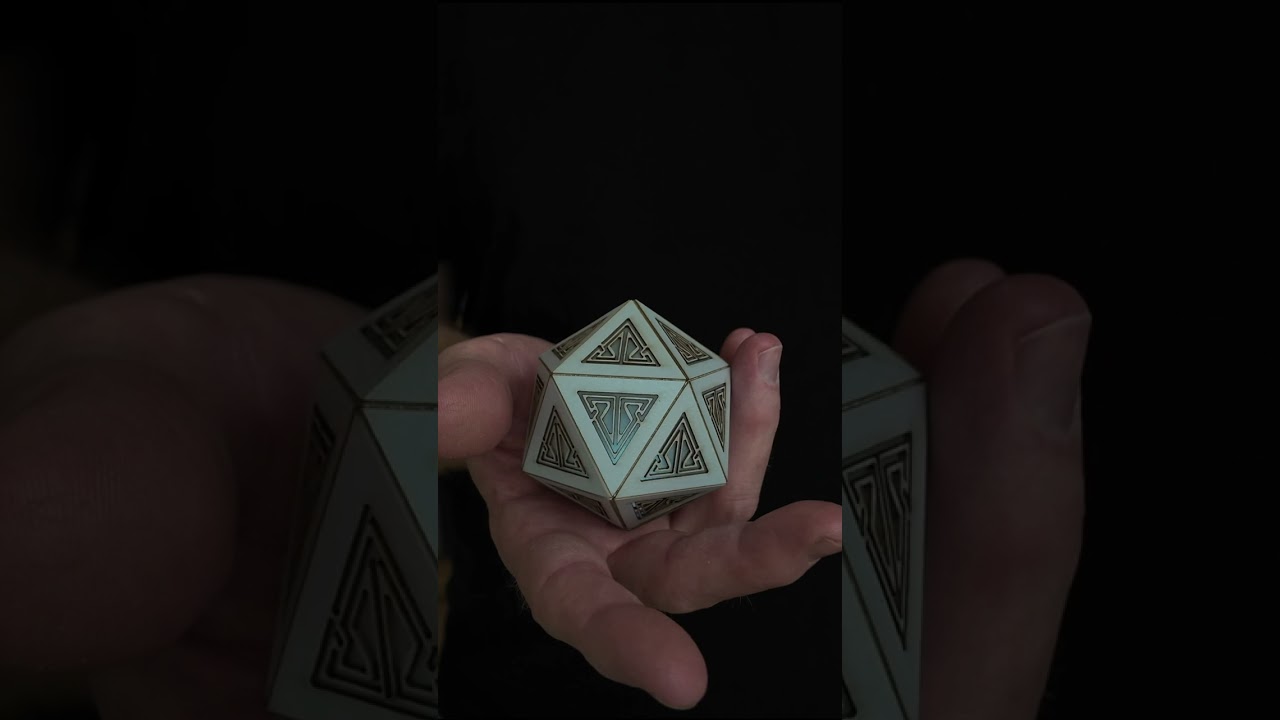

Since these are hollow, I thought it would be fun to put LEDs inside of them. I designed a triangular key pattern for the faces of an icosahedron, cut that as latticework into the faces and, added an inner layer of translucent vellum as a diffuser.

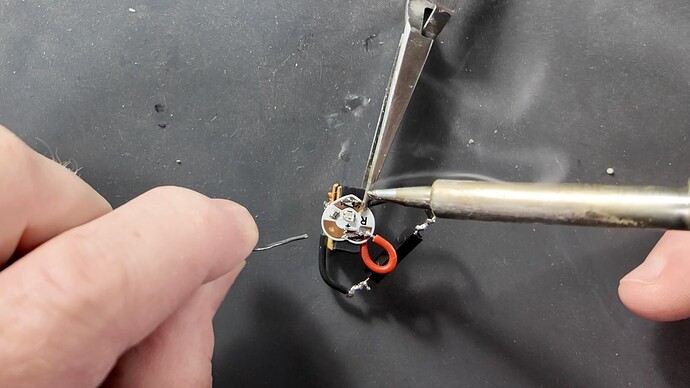

I built a couple different circuits using CR1216 coin cells and Chibitronics Circuit Stickers. The first version uses copper tape for the circuit and, leaves the switch on the outside.

For the second version of the circuit, I cut a little battery clip out of Baltic birch, added contacts I made from copper tooling foil and, soldered it all together with a reed switch. That version goes completely inside and, activates from the outside with a small magnet.

I made a video showing the whole process for a plain wood veneer dodecahedron and icosahedra with both circuit versions.

I also stuck the basic pattern files up on my Evermore Studio site.

Higher res video of the animated icosahedra:

I am still experimenting. So, there might be updates at some point. Let me know if you come up with any clever variations or changes!