If you have grass you probably need to cut it periodically. If you live in New England your mower has undoubtably encountered our local crop of granite, while doing so. I have a Cordless Ryobi 40V self-propelled mower, which is great on the farm as it is silent around the horses but to let the motor have an easier time they make the blade super thin, but that means it cannot survive too many granite encounters, and the Ryobi blade can’t be sharpened because it gets really banged up being so thin. So when I found the Revo 6 replacement which makes your mower into a giant 6-bladed string trimmer so at the barn when I am mowing the riding trails where there are a ton of rocks, I wanted to use it on the Ryobi.

Original Ryobi Hub with blade

Hub without blade

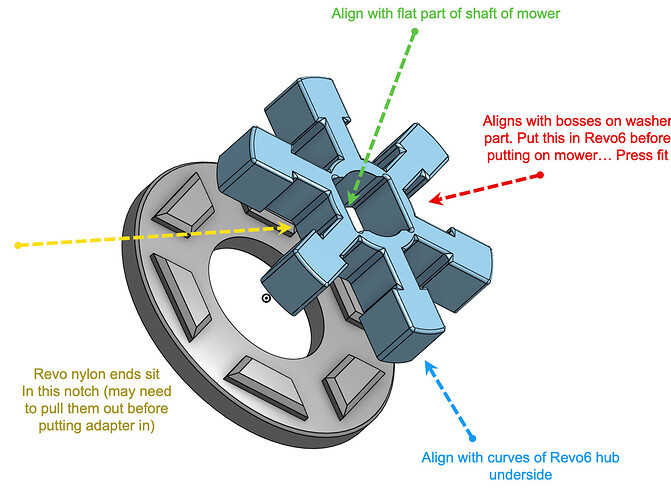

They don’t have a perfect adapter to the motor hub. But that’s a CAD challenge not a barrier. The mower hub has a complex keyed set of holes and flattened bolt to grip the nylon hub, and The Revo has a modular almuminum machined hub with an insert to match a mower’s hub. However the Revo didn’t support the Ryobi’s funky hub.

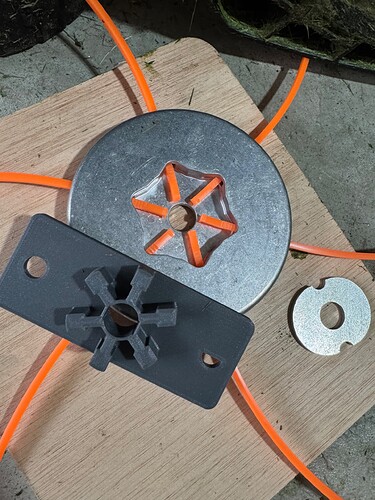

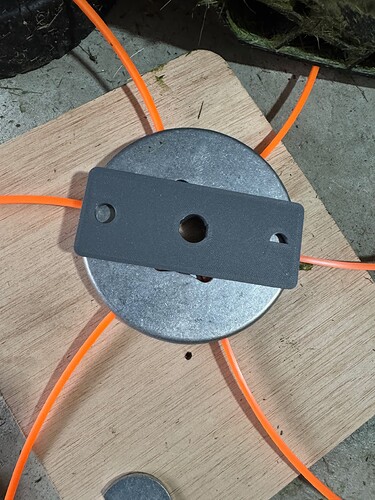

Inside of the Revo’s hub and my design test print in PLA (The rectangle was to let me hold it and more easily pull it in and out.

Perfect friction fit

The first part was making the star shape that would grip the Revo without interfering with the filament ratcheting mechanism that allows you to change filaments.:

I discovered that Ryobi had a keyed washer under their hub unit so figured there was a reason so had to add that in the end:

Final version printed in ASA installed after use (note it is “upside down” to fit over the Ryobi hub). The owner of the company answered my post about it, super nice guy and was interested in how I’d made it work.

I posted it on Printables including the STEP files, and it’s now done 8 mowing sessions without any problems. Well that’s not quite accurate, the one flaw in this (not my design flaw) was that the Ryobi sets the motor speed by the drag on the blade so when cutting through deep stuff it speeds up to not get stuck but the Revo of course doesn’t transmit a lot of force so it runs at the default speed (in really thick grass it did speed up). On the plus side it is even quieter and now runs at 58db which makes it about as loud as a room fan, easy to talk over, no ear protection, and I tested running over a large rock, and you just get the thwap-thwap you get with a string trimmer, instead of whirling death. At the barn I didn’t need to worry about hitting rocks (although that does wear the filament much faster of course)