As one of the members who has been around the glowforge community since the beginning, as well as one of the admins of the facebook group, and a general laser enthusiast, I have heard (and experienced) quite a bit of consternation over alignment.

I wanted to take this opportunity to go over laser interfaces in general and where the glowforge falls in.

From the very beginning I have been interested in achieving the most accurate alignment possible when using the glowforge (or any other laser). A good portion of my early post history was dedicated to this topic. It is one of the main reasons I purchased a glowforge, and has become one of the reasons I still love my glowforge and tout its capabilities whenever I can.

Alignment Types

Having used a number of lasers ive found there are generally 4 ways one can attempt to get accurate alignment of engraves/cuts on a piece of material or object. They are as follows:

- 0,0 corner placement + the use of measured offsets

- head/red dot alignment based on the current location of the red dot on the work area

- camera based optical system which images the bed and materials

- fiducial placement via registration marks gathered by the camera system(s)

The first is the most basic and common method of aligning something. You find the home position of the laser head (usually the top left corner of the bed), and used that as the origin point for a cartesian based grid where you can measure offsets from that position in order to determine that your material is where the design is set on the virtual bed in the application you are using. Practically every laser has this type of system as a base (the glowforge, however does not 100%).

The second builds on this by allowing you to use a laser head equipped with red dot output to be moved over your material via jog controls. The position of the red dot acts as an anchor to which you can attach your image in the software, giving you better visualization of where the output will actually be. Many of these systems will also allow tracing of the outer perimeter of the job to be done to show the full material utilization which is very helpful.

The third is one we here are all familiar with, the camera based system. There are a few variations out there, including one that takes multiple photos of the bed and stitches them together (poorly), and some open source versions that use fisheye lenses similar to that of the glowforge. Being newer, most of these are still works in progress and provide semi-accurate placement, which is great for getting the best out of scrap materials etc.

The last and most accurate is fiducial/registration point based alignment using cameras placed on the laser head. A number of manufacturers have started using these to give incredibly accurate alignment for jobs. Special marks are placed on the workpiece which allow the camera to determine material position and rotation, and automatically adjust the job to match those values ensuring an incredibly accurate cut.

Expectations

Many people, myself included, expect lasers to be incredibly accurate in every aspect. If something can engrave less than the width of a human hair, we should be able to easily cut a hair right down the middle right? Not quite.

While it’s easy to accurately plot laser output, one of the most difficult tasks is to have your material/object in the right place while that is happening. This was one of the major driving factors behind the camera systems that have been showing up in lasers recently, especially since the glowforge landed on the scene. As it is still technology in its infancy, it still has a good ways to go until its going to be able to turn 1 hair into 2 (split longways at least), or seamlessly match up 2 engraves without a gap or overlap.

Some users report up to 1/4" or more offset in the placement of their design on their glowforge to the actual output. This is a long way from the promise of easy, accurate placement we were promised at the beginning. It has frustrated users to the point where alignment posts are commonplace, crazy workarounds have been invented, and some users have even decided to switch to another laser brand because of it (theyre in for a shock once they get their new lasers! more on that in the next section).

While it is frustrating, I do think glowforge will ultimately keep their promise! Snapmarks has been released in beta, and has shown to be incredibly accurate, giving users the ability to accomplish what has, up until this point, not been possible, and there is more to come from that front im sure.

Surprising Comparisons

For many laser users, the glowforge is the first laser experience they’ve had. When things haven’t gone as expected, the general urge is to try something else. As I am constantly learning about the tools I use and what is available, I have tried many lasers, and have seen many others go down the same path. There are many lasers out there that offer superior speed, more power, and a handful of other features that the glowforge does not have. Surprisingly, when it comes to alignment, they ALL have problems… even the big 3 (Trotec, Epilog, Universal).

Having used snapmarks for a while now, Ive grown quite reliant on it, and use it often, especially for accurately placing engraves on pre-made objects. It has been great! Seeing that the big 3 also offer camera/fiducial based alignment systems (usually costing $5000+), one would assume that theirs must be bigger and better than a laser that costs half as much as one of those cameras. … and heres the kicker: that is a false assumption.

The ability for any of those laser systems to properly align an image to be engraved, to fiducial markers, does not exist. Beyond that, at this point in time, none of those systems even allow you to manipulate the rotation, width, or height of images to be engraved in their UI. The only thing the incredibly expensive camera systems do at this point, is to allow a vector cut to be performed with orientation corrected via the fiducials. To quote one of the technicians: ‘the algorithms are incredibly complex for the cut, and unimaginable/impossible for raster engraving images’. We all know this isnt the case, because the glowforge can do it, but everything is relative.

I think its fairly easy to take for granted the seemingly basic functionality the glowforge affords us. I know I have to a degree, and Ive been pretty shocked to see the state of other much more expensive laser systems out there recently. To think that this small company who seems behind in their promises, is actually so far ahead of the competition in so many areas is crazy right? Especially when many of them have been in the game for 20 years plus. I can tell you one thing, theyre all scrambling to catch up.

The Current Reality on Alignment

As of now, if you have snapmarks enabled, you have one of the most, if not THE most, accurate alignment systems available in laser engraving systems today. As crazy as it seems, it’s the truth. The only company that could offer something similar was Universal, and only on their XLS line ($100k+), and it came with a massive number of caveats related to distortion and skewed images. No thank you.

Where Things Are Going, and Could Go

I think the glowforge has disrupted the laser industry quite a bit with their innovations. Yes, they still have some of those launch campaign checkboxes to tick, but know that no one else in the laser industry is anywhere close to solving the things glowforge is working on. I like what Ive seen so far, and Im looking forward to seeing where they take things in the future. The things they are working on currently are showing a lot of promise, and the flexibility they’ve designed into this first gen machine can allow for even more options should they choose to do so.

Snapmarks opens up the ability for lid-camera auto calibration in order to fix optical placement accuracy of the lid cam. This could easily be accomplished simultaneously with the launch of their new invisible QR code based materials, where the entirety of the masking sheet is covered with UV QR codes. By using the lid camera to see each QR code, and the head camera double checking the placement of those, de-distortion maps can be generated to perfectly render the bed image exactly where it should be, meaning no more misplacement.

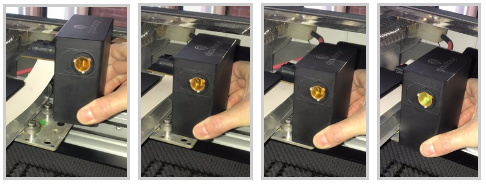

The swappable heads can allow for new features to be added, such as a head with a red dot to be built in (or they could use the current depth detection red dot) to allow for tracing of cut/engrave areas on the materials for double checking that your material is really where it needs to be. (before they fix the optical placement via snapmarks that is).

Real time depth sensing can allow for them to detect edges of materials, along with their height, allowing them to build a 2.5d model of your material, accurately positioned on the bed, providing the ability to perfectly engrave a flip sided image on non-symmetrical objects.

Newer heads can be released to enhance these capabilities and keep your machine up-to-date and viable much longer than any competitor machines.

If they keep it up, I think the future is bright for glowforge.

either way, 2 minutes (which is what it takes on my system) is worth it for knowing that my print is going to be dang near perfect.

either way, 2 minutes (which is what it takes on my system) is worth it for knowing that my print is going to be dang near perfect.