So Koptis (my ![]() ) has been patiently awaiting for attention (been a while since he got to do something).

) has been patiently awaiting for attention (been a while since he got to do something).

Noticing that Snapmarks are still and beta, but not out to everyone, had to revert to a paper jig design.

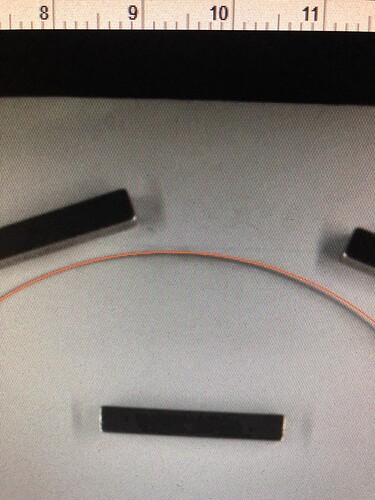

Koptis is dead on for repeated cuts (around 10) to minimize material consumption:

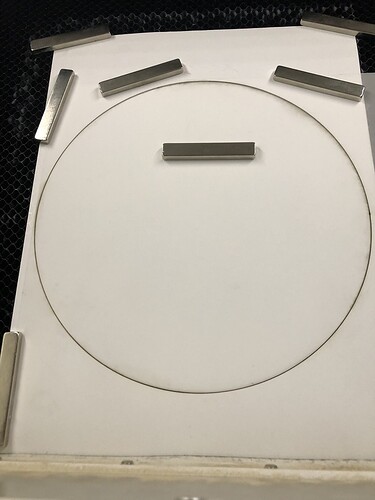

The mylar diffusing filter squares are 12" x 12", but the LED lighting is a round 8" housing and I have LED lighting bars that need 2" strips that can be made out of the scrap (another project to gear up for ![]() ) This requires minimal waste by placing the circle as close to 2 edges.

) This requires minimal waste by placing the circle as close to 2 edges.

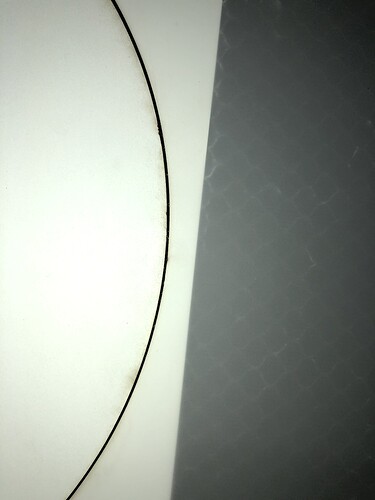

So you can see how close the mylar is at the jig layout. The black gap is because the internal paper circle has bumped around with the 9 previous cuts and gets a little shaved of each time.

Now the GUI interface has not been adjusted for positioning (between cuts), but the display is all over the place between cuts as seen below:

Now the burn goes with dead one accuracy:

With this post picture:

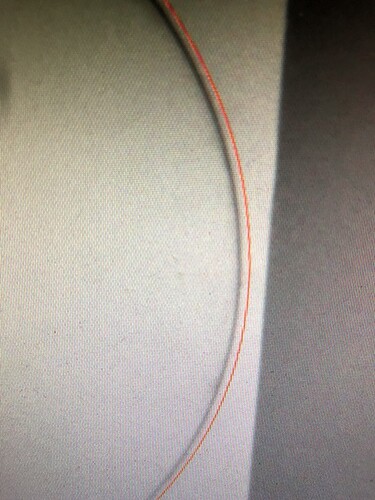

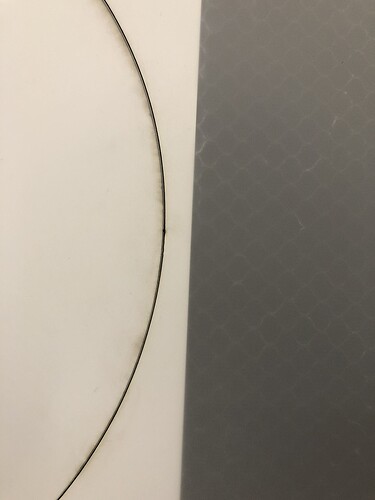

And the detail close-ups:

With the 8" mylar circle removed details:

So Koptis (well Glowforge ![]() ) is extremely accurate when jigged, but the GUI definitely needs those Snapmarks!

) is extremely accurate when jigged, but the GUI definitely needs those Snapmarks!

Looking forward to making use of them.