Made a little gift tag / ornament combo with medium walnut proofgrade tonight, and, well, it was a learning experience. On the way to the recipient, the wood snapped on the grain in a thinner (3/4") part of the design. I am not much of a woodworker but it looks to me like it fairly brittle anyway, so here’s where the learning portion comes into play: I am wondering what everyone does to reinforce designs. Tape an identical cut of veneer cross grain over the back, maybe? Was it maybe just a bum proofgrade sheet? Something else?

As usual, we can’t tell you much without a photo. With the MDF like core you have to leave a bit of material everywhere.

Think this was hardwood

The item is gone now, I can’t show you a picture, but it was about 4" long, with a 3/4" straight edged bridge on one end. The obvious problem with that cut is that the grain went the wrong way (next time I know to check under the masking).

I’m asking more generally how people stabilize their builds as the walnut is way more brittle than other woods I’ve used so far. I didn’t know the core of proofgrade woods was MDF - that can’t be right?

If it’s plywood, the core is MDF. If it’s hardwood, then it’s all wood.

Generally speaking, the harder the wood, the more brittle it is. And as you discovered, grain direction makes a big difference.

It was a sad moment!

Yeah, it sounds like you used hard wood, hard wood breaks very easily along the grain, a lesson I learned the hard way.

I guess if we’re lucky enough, we all get there in our own time.

I don’t use the PG hardwood in anything single-layered. It’s too easy to break it. Plywood is much more durable.

For me, the Proofgrade is much stronger than hardwood along the grain. Against the grain maybe not.

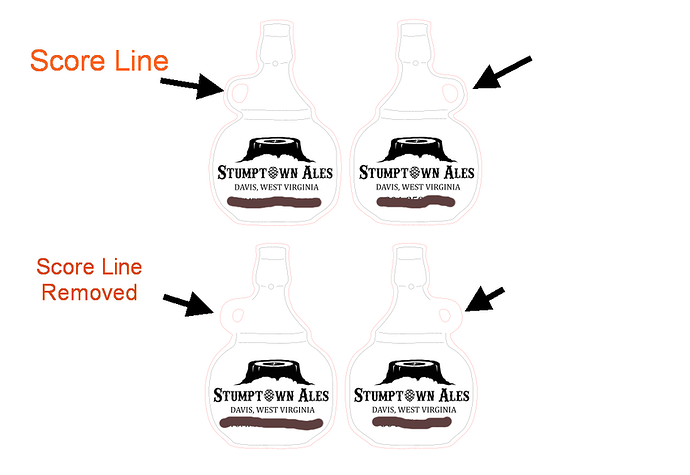

Of course it also depends on whether there are other design components on the surface of the material. For example, I cut about a hundred keychains that would fail at the ring after about 3 months of use. Without thinking I had cut score marks on both sides of the keychain hole leaving only about 25% of the PG Cherry plywood to hold at a stress point. Redesigned and replaced all of the keychains.

oh, ouch. Thanks for that advice!

I have used walnut recently, and it was only 1.6mm thick (about 1/16 inch). I made some bookmarks with them- as I wanted something thin, but strong enough to survive the hands of kids (this is for an upcoming “Santa Shop” for elementary school kids). When I cut the bookmarks “short grained”, they were very brittle and easy to break. When I cut them “long grained” they were much stronger. Of course, you could still break them fairly easily if you bend them from the sides, but from top to bottom they are good.

I think you just have to pay attention to which way the grain is going when using hardwoods. Or just go with a thicker hardwood, like a 1/4" and you don’t have to worry about it as much. (Or plywood as others have suggested). I have some of the 1/8" Proofgrade Hardwood but I haven’t tried it yet. I wanted something a bit thicker for my coasters, so I went to my local wood supplier (Kencraft) and they have a really awesome selection of hardwoods and I’m starting to get the settings dialed in.

I used the 1/4" hickory from this company. They do ship but it’s kind of pricey unless you’re getting a lot of it.

I used full/130 to cut (3 passes), and full/1000 to engrave. Here is a pic of the coasters cut from 1/4" Hickory.

Oh those are lovely. Thanks for the tip about settings and kencraft too. I’m going to do some experiments today, maybe the answer is plywood.

I considered doing a coat of ca glue on some keychains that I made, as the ring was prone to failing. I ended up ditching the ring and putting a hole into the body of the design. Realized how much time/cost/effort would go into covering 125 keyrings with a smooth coat of glue.

oh gosh yeah…