My experiment used non-PG acrylic, but I’m pretty sure this would work with all acrylic. I hate it when a nice design is marred by haze and other heat artifacts. Most come off with 91% isopropyl alcohol, but not always. Removing masking tape/paper after engraving almost makes me willing to live with the haze.

I have used liquid dish soap as a heat buffer/surface protector on glass when engraving. Turned out well and was easy to clean. I wanted to see if it would work on acrylic, too.

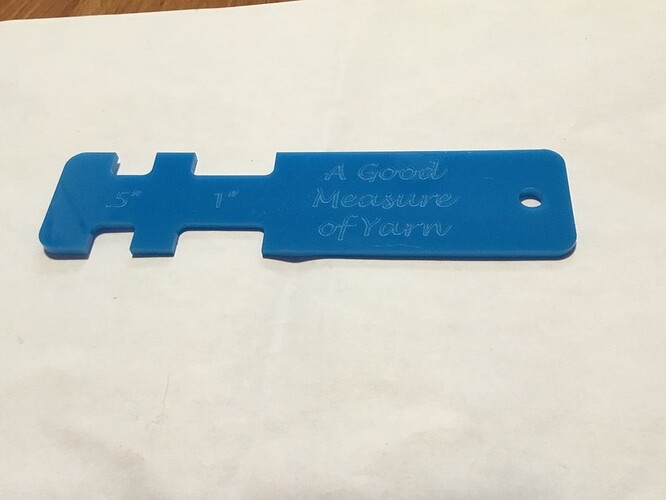

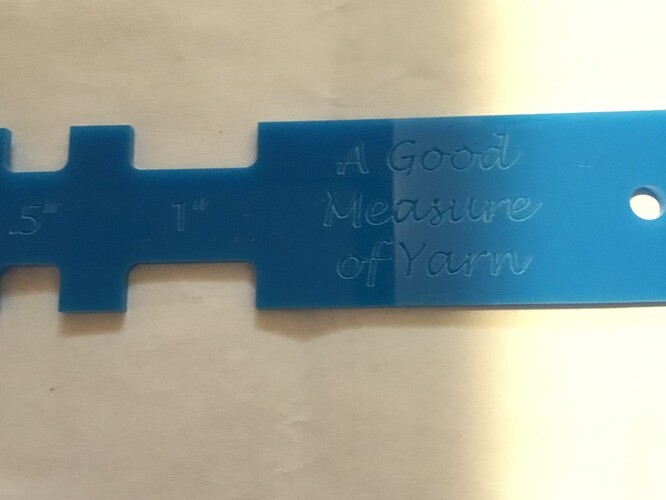

Seems that it works as well on acrylic. I made two yarn tools, one of clear and one opaque (so the design is on the reverse, or on the front for comparison). Since they came out the same, I’m showing the opaque one. Very clean, and did not need any alcohol wipedown afterwards.

first photo shows the piece after cutting but before cleaning. Make sure you smear a layer over the expected cut edges as well as the design area. 2nd photo shows the complete piece, and 3rd photo is a closeup. Showing them at different angles helps me find any smudges.

This is so much easier than suffering with masking.

[Edit: By the way, this is a way for spinners/knitters/weavers to evaluate their yarns. Wrap the yarn closely around the .5" (super fine yarns) or 1" (most yarns but not bulky) sections to find how many wraps per inch (wpi) you get. This helps determine the sett for weaving, or a yarn’s compatibility with other sizes of yarn.

I’ve also made a more robust one out of wood that includes a 2" section for bulky yarns.]