I would love to make bigger, thicker things and have been considering adding a CNC carving/cutting machine to my GF. Been drooling over one that hasn’t come out yet and that I can never remember the name or manufacturer of…

Good luck. I haven’t used my CNC router since I got the GF.

Depending on what you want to do, don’t forget that the glowforge, thick draftboad or acrylic and a trim router will take you a long way.

I happily use both. I have a Shapeoko (my second) and I find it incredibly useful for the area size and depth I can work with.

I just purchased a Shapeoko 4 to supplement my GF.

Try making this on a GF…

Upcycled a Corian cutting board to a shower caddy.

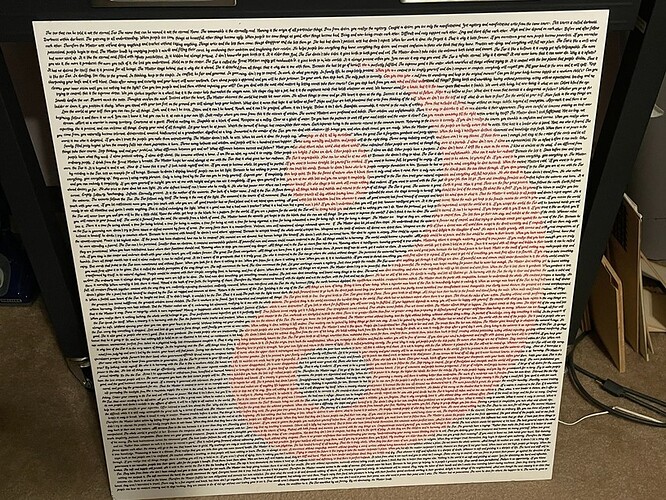

If you’re a lunatic, you can also make a pen holder and use the CNC to write the entire text of the Tao Te Ching, in the shape of a Yin/Yang with magic markers on a 30 inch square piece of GatorBoard.

But maybe that’s just a me thing… ![]()

I’ve got a OneFinity Journeyman (48" x 33" bed). But with tiling I can run infinitely long by 48" wide stuff in it. Lots of things I couldn’t touch with the GF like furniture, guitars, stone (soap stone carves very well with a router or spindle and carbide bits)…

Once you’ve got your CNC router, it’ll be time for metal - I have a CNC plasma for 2D work (& 3D thru bending and welding). My next metal adventure will be a CNC mill. I’m still thinking about a Tormach like doc’s but there have been a couple of new options out there for the hobbyist/pro-sumer market that might be the ticket. Just waiting to have the new shop space ready.

Two layers of acrylic and weld-on. Two layers of bamboo with titebond III.

But I get your point ![]()

This was a replacement for a two-layer acrylic tray as you described. It tended to grow mildew along the seam between the layers.

![]()

You. Definitely you.

Well, sounds like I’m going to have to try it once they decide that it’s definitely a tear in my meniscus and I survive the surgery.

That much quality and effort deserves marble at the least. Though even now I am trying to figure out what of my precious varieties of woods deserves to be sacrificed as a proof of concept to the Magic Canvas (if we use it to simulate a carpet, will that make it a Magic Carpet? Carpet seems a much better upgrade than plain canvas.)

I’ve got a few different types of 3D printers, a 4-axis benchtop “knee mill” (like a big milling machine scaled down, the 4th axis lets me turn pieces so I can kind of use it like a lathe if I need to) that’s good for precision work and cutting metal, and a 3-axis “gantry” router type machine that’s good for larger workpieces like wood, plus of course, a Glowforge. (been jonesin’ for a Wazer water jet cutter, but the consumables are too much trouble to deal with as a hobbyist).

What do you want to make with a CNC? How much money do you want to spend on a CNC?

These are the two questions you must answer, first.

I just got the same CNC. Haven’t had time to set it up, but hopefully in the next month I’ll start that learning curve…

The good thing about this stuff is the same SVG files can be used on any of the machines with just the toolpathing being modified from one to the other. I often do a mockup (sometimes scaled down) on the GF with a project that I then bring into Sheetcam to path for cutting in steel or VCarve to do wood or plastic that exceed the GF’s abilities. A lot of design-once, cut-many across the machines.

That’s very nice. What did you use for the cuts? I find cutting Corian to be very difficult on my Glowforge.

I used a .25" upcut end mill for both the pocketing and the contour cuts.

The only router I have at the moment is the Dremel attachment one.

Keep an eye out at the home improvement stores. Sometimes you can pick one up for 60-70 bucks. Add a guide bit and a template made on the Glowforge and you are in business.

I was looking to have something like that which would use my Flex shaft. I bought the Dremel one thinking it came with the motor but sent it back when it did not. The Dremel one can only use the Dremel motor.

Great for what it does, but limited.