Spent some time today playing with face to face adhesion, and figured I would share my experiences/results with everyone.

I need to adhere clear acrylic to colored acrylic and have as little visible mess as possible. A while back I purchased some SCIGRIP Acrylic adhesive, so I figured this would be a great chance to test it out.

Quick note, this stuff is incredibly TOXIC, so wear as much protection as possible and keep your area very well ventilated.

Application

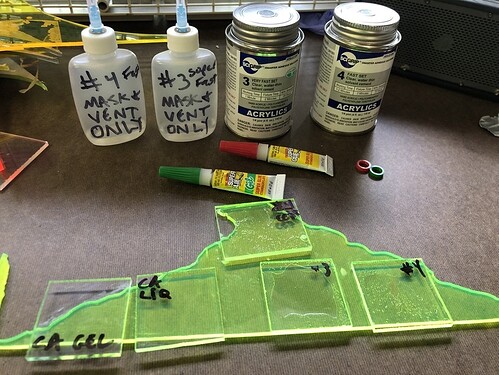

So I tried each type of glue with a small piece of acrylic.

The right 2 were the SCIGRIP #3, and #4. I used the capillary method for those, by placing the acrylic down and running the needle of the applicator along the edge. I ran it past a few times to see if I could get full coverage. It didnt happen.

I then attempted to make a puddle using #4 (its slower to eat the acrylic), and place the piece on it, and then go along the edges to have everything filled in.

All of these left bubbles and air pockets inside which just isnt going to work for me. They do bond really well though

The two on the left were gel CA and liquid CA. Those worked so much better here, but are difficult to keep from moving and can be messy in their own way. I will probably be using these for the large connections.

Cleanup

Glueing two faces together is difficult in that determining how much adhesive to use is close to impossible. Glue will pretty much HAVE to come out the sides if you have to have 100% coverage. This causes problems of its own.

When SCIGRIP is not between two pieces of acrylic it just eats it and leaves a white spot.

CA glue leaves foggy/crumbly mess as well.

Which one is worse? SCIGRIP because it actually eats the acrylic away and its difficult to clean this off. Nothing works to get rid of it except other solvents which sounds troublesome.

CA glue is also a pain to get off as well, but its an additive adhesive, so its not actually doing damage to the material.

The answer here for both of these is acetone. Acetone is also a solvent, albeit a much weaker one. It can remove extra CA as well as help to get rid of white spots left by #3 and #4. (It also pulls sharpie off of acrylic… so my labels went bye-bye lol)

WARNING: Acetone can damage/weaken acrylic and cause crazing/cracking, especially in corners.

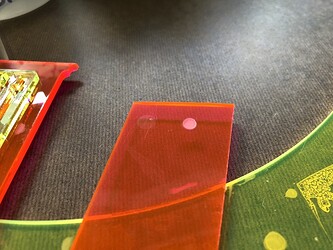

In the two photos below, I had applied too much gel glue to the far left piece and it was foggy everywhere. Acetone followed by a quick wipe with a soft eye glass cleaner got rid of almost all of it.

I wanted to see if I could do anything to get rid of the white spots from the SCIGRIP, because im clumsy and know I will spray it on places it doesnt need to be. This is a test piece with two spots for before/after.

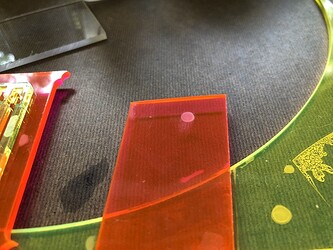

I tried rubbing alcohol and zeiss wipes first. Nothing. After that I tried acetone, and after one pass it looked like this:

After the second pass and a wipe with a glasses cleaner it was almost imperceptible!

Conclusion

So it seems for this application, CA glue is going to do the job much better than SCIGRIP/Weld-On. Any overflow will easily be remedied by acetone.

For butt-end joining however, SCIGRIP works REALLY well. I definitely recommend practicing first and wearing gloves.

I hope this will be useful to some out there. Feel free to leave any questions here for me. Happy glueing!