I figured. I’ll start a new topic to write down my experience. I bought some craft felt at a local hobbystore. I had never before worked with felt on a laser and I have a design that’s not easily suited for the material but I don’t like to give in.

I have 2 thicknesses of felt in a couple of colours. I’m pretty sure it’s all a polyester/wool blend.

- 3mm stiff dark grey felt

- 1mm floppy white

- 1mm floppy grey

- 1mm floppy blue

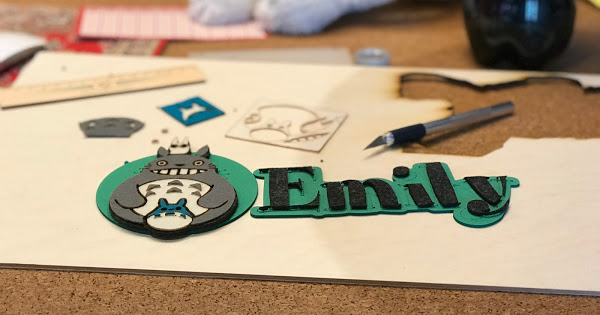

The design I’m going for:

This was my first try. From a distance it looks great, but up close it’s not the quality I’m aiming for. The dark grey had melted all small details and the thin felt all charred up around the edges. Especially noticeable on the white. The smallest intricate parts got lost in the proces.

The good:

After a few tries I got the settings for the 3mm dark grey felt just right. 300 speed, 20 power, 3 passes. This preserves as much detail as I need (look at the whiskers and the scribbles on the letters. There is also an engrave on there. Barely noticable. 500 speed, 5 power, 1 pass.

The bad.

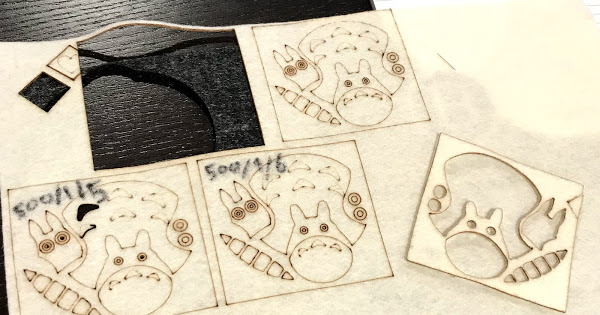

I’ve been tinkering with the thin white felt and I can’t get the settings right. Anything I try results in charring. So it doesn’t matter if I go low power and multiple passes or just cut in one pass.

The real cut I managed was at 300 speed, 40 power, 1 pass.

The other three tries are 500 speed, 1 power, 5 passes, 500 speed, 1 power, 6 passes and the upper right corner is 450 speed, 1 power and 6 passes. All three did not go through.

The scoring, those little triangles in the middle are done at 500 speed, 1 power, 1 pass. As you can see that results in burnmark in the bends where the laser had to slow down.

I’m going to try and use an engrave to see if I can get cleaner scores and maybe even a cleaner cut.

The charring is not as noticeable on the grey and the blue although I would like it to be even less.