That would be cool. Keep in mind, though, @gdmccormack, that the leather types you listed actually exist as combinations of ingredients and treatments–almost infinite combinations. Here’s what you deal with on each piece of leather:

Species: cow, pig, kangaroo, deer, alligator, sting ray, salmon, etc.

Age or type of animal: bull, calf, doe, etc.

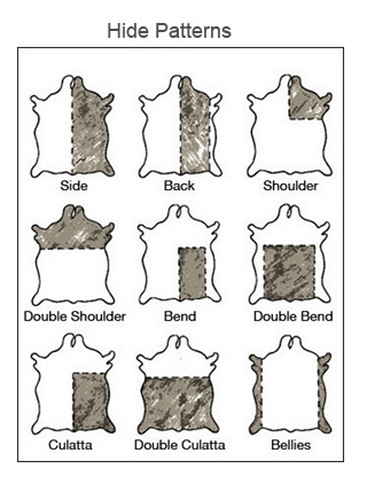

Cut: whole hide, side bend, belly, etc. (see below)

**Weight,** which is actually thickness (see below)

Tannage: veg-tanned, chrome-tanned, alum-tawed, oil-tanned, brain-tanned, some mystery combination thereof??? such as latigo (veg+chrome) and bridle (veg+oil), etc.

Treatment: nubuck, freezing, ironing, sandblasting, etc.

Colorant: none, oil-based, vegetable dye, wax, alcohol-based, acrylic-based (many of which can be either a penetrating or surface treatment), etc.

Finish: none, carnauba wax, beeswax, acrylic spray, etc.

I think Glowforge is planning to sell materials, and I’m sure they would be able to guarantee the composition of their leathers. Speaking from experience, when you buy from a leather factory, you also have a good chance of being told the truth about what you’re getting, though if you get a new sales employee, you’re mostly getting good guesses. When you buy from a retailer like Tandy or craft stores, your chances of getting any real information about the composition drop dramatically, except when you buy rawhide or the simplest veg-tan stuff that’s meant for tooling. When you pick up a cool jacket at the thrift store or a sidewalk couch, hoping to upcycle them, you’ll have very little clue, and the default guess should be chrome-tanned.

So, if we’re going to do a database of leathers (which I think is a STELLAR idea, we should have the tester note everything they know about each sample (including source), all the settings they used, etc. I think the community would get the most benefit from tests of common leathers from known dealers (veg-tanned natural-color kangaroo leather in the K-Craft line from Packer Leather, Tandy’s split pigskin garment suede, etc.). That way, people can have consistent results and be able to order online with confidence.