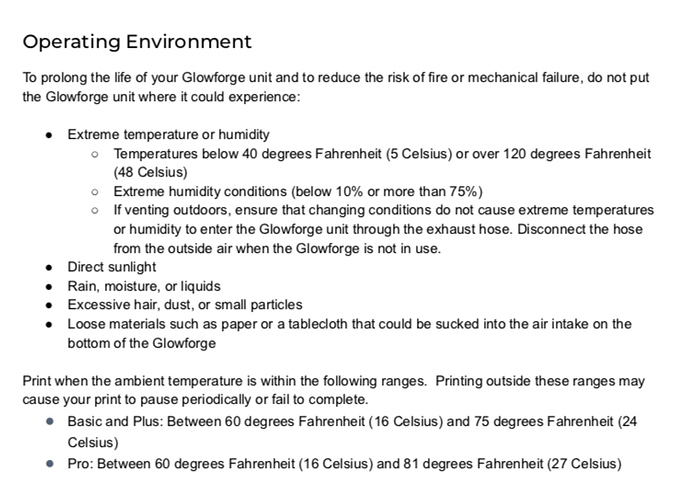

Last week we had a solidly good overnight cold snap, and it occurred to me that the unheated garage where my GF lives could become a big problem as we roll into winter. Moreover, I figure it’ll only get worse since I vaguely recall seeing the lower temp spec in the manual was 40 degrees, but the outside temp will likely go negative by Jan/Feb.

First things first, I browsed the forums here to see what people have done and get some idea of what works and what doesn’t. Next, I went on Amazon to shop for electrical heaters, hot air blowers, etc, and to see if there was any obvious commercial solution. Yes, there were some things available, but I didn’t want to spend a massive amount on electricity by heating the entire volume of a poorly insulated garage all winter. And of course, it’s too late in the season (and too expensive at the moment) to properly insulate/finish the garage, so that’s off the table too.

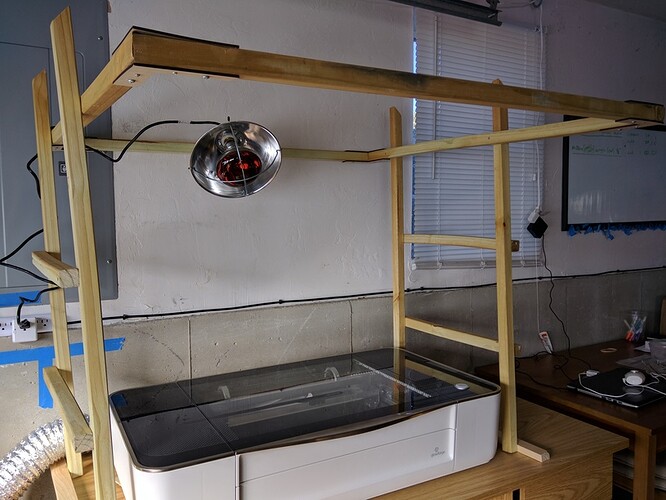

So, I figured I’d do something a bit more… Custom. Without further ado, I present the Smart Hot Box. (Pics first, description below)…

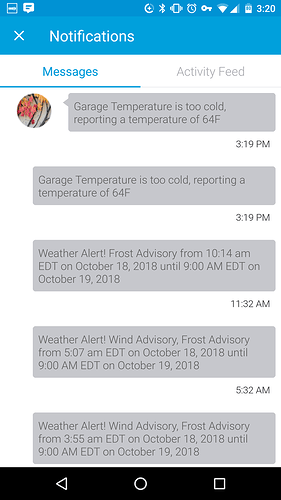

Basically, the idea was to create a large open-top box lined with reflective mylar illuminated by a 240 watt hot lamp. The obvious problem comes from leaving the heat lamp on too long, which could damage the GF. So I leaned into my home automation setup to produce a custom temperature controller. Essentially, when the hot box is over the GF, there’s a little tempertature sensor sitting on the GF that talks to a local hub. Likewise, there’s a Smart Switch that controls the light. When the sensor gets too cold (45 deg or below), then the hot light automatically turns on. When the temperature stabalizes to the threshold 45 deg, the light automatically turns off. A few thoughts:

(1) I currently have only one redundanet method in place to turn the hot light off if it’s on too long. However, considering the nature of technology and it’s occasional failures, I’ll be setting up another emergency off switch as a second redundant regulator.

(2) The lumber used to construct the hot box’s frame is just a fe wpieces of old, warped scrap pine I had lying around held together with mismatched screws and nails.

(3) I laser cut the angle brackets that hold the frame together… Because why not?

(4) The reflective mylar is the same emergency foil blanket hilers like to carry around… Y’know… For emergencies.

(5) So far, the hot box generally works and I can monitor all temperature logs remotely as well as manually override the hot lamp from anywhere that’s connected to the internet via my phone app.

(6) The open-top concept is two-fold: first, it gives the best signal when connecting the temp sensor to the hub, and second, it allows heat to rise and circulate a bit more (useful if the automation fails… because I’m paranoid about cooking the GF). Yes, it’s inefficient with heat radiating away, but that’s a compromise I’m willing to make because the mylar walls balance this loss by reflecting some of the lamp’s heat back in.

(7) Total cost was around $30 + time spent improvising the design (made the hot box’s design up as I built it).

(8) The box easily lifts right up and over the GF. When I wanted to do some cutting today, I just picked it up, put it aside, plugged the GF back in for power, and fed the ventilation tube back outside. Putting the hot box back on was just as easy.

(9) Who knew home automation could be so useful? ![]() Anyway, when some future person is wondering how to handle their GF in a cold garage, I hope this project narrative is helpful for their decision making process.

Anyway, when some future person is wondering how to handle their GF in a cold garage, I hope this project narrative is helpful for their decision making process.