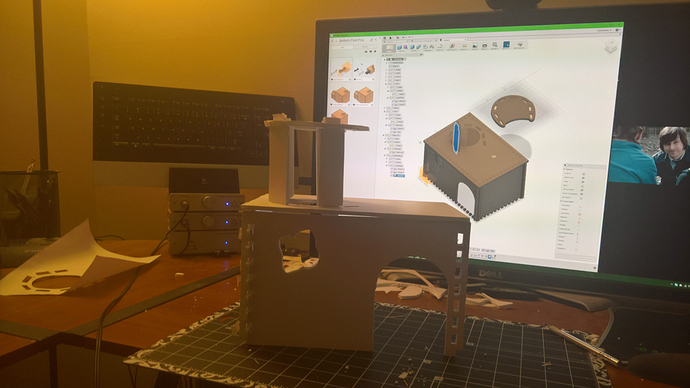

so if some of you re call I plan on making chinchilla houses so I have been playing with a few designs. decided that on the screen the sizing may be deceiving. so I said ok ill just print the vector on paper and tape it together nope all fell down. so then I said ill tape the vector to foam board and start cutting it out and see if all my joints work correctly . welp this has been 5 hours and I feel like I have not accomplished a thing. I am using a exacto, any one know of a better way ?

I’d use a Silhouette Cameo and either card stock or foam. Great practice for the Glowforge.

eh those start around 300 though ? and at that point I could k40 for a few hundred more. was trying to keep it very low cost

I’m not aware of any options between a sharp xacto with a straight edge and a cameo. I will say that the software with the cameo will be far superior to the k40.

More like max out at $300 (for silhouettes machines, other brands are pricier). Silhouette machines are often sold in bundles with different accessories and supplies, which usually accounts for the price difference.

You can get a used one for $100-150.

will the cut 1/4 foam I am having trouble finding specs

I have a basically new curio I don’t have room for. PM me if you’re interested. Has all the tools and accessories to make it functional. I just have way too many tools. Cameo Curio 3D printers, k40, and a glowforge promised. I received the curio just days prior to ordering the gf.

The curio will cut up to 1/8 or 4mm. With the deep cut blade. Even wood. Where it shines is chipboard, which doesn’t work so well in the laser.

What about printing plans out, taping them to the foam (is foam-core ok for chinchillas?) then cutting it out? Kinda like THIS.

EDIT: now that I look at your first image again, I see that you may already be doing that. My bad.

Looks like those little guys will be living high on the hog.

god no nothing foam is ok for them they eat everything, so I only have certain woods I can use. it was more of to cut it up throw one of them into a hole and see if they fit. or to see if the whole thing was to small. yes I was print it out then tapeing it on and then cutting it out

only bit of advice I could give would be to ditch the chinese #11 exacto blades, and use a snap-blade cutter with high-quality blades (Excel & NT Cutter are my favorite, but OLFA blades may be easier to find for at homedepot or a hobby-store).

The fixed-blade style just makes it so easy to leave a dull blade on for far too long, which results in cuts taking longer and having to “saw” through paper fibers (crushing and fraying the edges while you do) instead of “slicing” through cleanly.

Also remember to dispose of your used blades properly and carefully. I have a little plastic blade-disposal container that came as a freebie with another purchase that I keep in my mobile kit. At the shop I use a very fancy, custom-designed steel receptacle.

It is a soup can glued shut with a slot punched into the lid.

You could get a band saw. Not sure how well those work on foam. But that can run you as low as free on Craiglist if you are lucky, or $20 in a garage sale or pawn shop.

You could swap to styrofoam and make yourself a hot wire cutter too.

I am in a 2nd floor condo. Im thinking maybe dermal

I agree with @jbv. Use a nice snap blade, and make sure you cut at a very low angle. If you hold the knife too high you will use less blade surface, and cause more damage to the foamcore. This stuff KILLS blades though, so you will have to switch out often. I think Adam Savage just put out a video about foamcore which I havent watched yet. Let me find it…

Here we go. Adam Savage making a house out of foam core. Maybe some pointers you can pick up from this:

If you want a more automated approach here is a DIY cnc machine: http://forum.flitetest.com/showthread.php?24251-Cutting-foam-sheets-with-a-needle!

In that thread they mention some folks using a sewing machine to cut the foam.

Since we are waiting a little longer to get our 'forge my wife and I are going to build one so she can start making her prototypes out of foamboard

No, I’ve never seen foam successfully cut with it, although that doesn’t mean someone isn’t cutting some type of foam successfully. The clearance is pretty low. But I’ve cut wood veneer with it (not really recommended – the cut pieces fall free, which is not ideal, and it kills the blades) and you can supposedly cut chipboard with it, which might work well for prototyping?

When I need thicker or studier pieces, I just cut a couple and sandwich them together. If you decide to get one, I strongly recommend buying several cutting mats. I think I have 4 or 5 at the moment. Its way, way more efficient to be able to cut continuously, rather than cut, peel, new paper, cut, peel, new paper, and on and on. I find I’m the slow part of the process now – that I can’t peel the pieces up as fast as I’m cutting them.

Oh, this is a good idea! My sister used to use a bandsaw to cut foam for architectural models in college.

She cut all the skin off of her knuckle, too, while doing it, but she is pretty clumsy and they worked ridiculous, sleep deprived hours.

no I don’t plan on buying a curio