Yup did that too. Once I had it all apart before I put everything back together

Thank you so much for your photos. I’d like to take a closer look at your Carriage Plate belt while installed. Can you also take a photo of the pulley wheel? I’ve included some instructions below.

First, power off your Glowforge and remove the crumb tray.

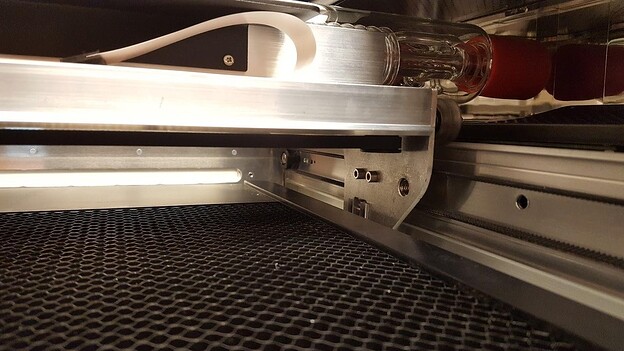

1.The belt under your laser arm with the head pushed to the left:

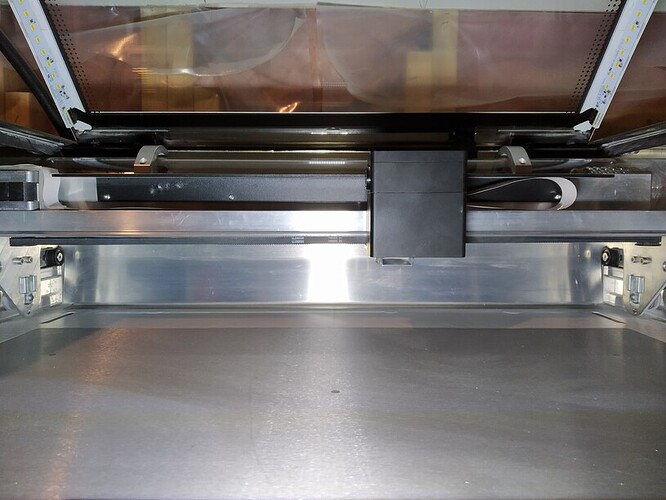

2. The pulley under the laser arm on the right side from the front:

Once I have your photos I will be able to continue investigating this.

We’ve tightened the belt and cleaned everything and cut the measuring tool again. You can see it’s better, but still much worse than the original cut we did when the glowforge first arrived. Besides tightening the belt, what else is needed to get the quality back?

Hi @bclmtaylor - thanks for all the awesome photos you’ve shared throughout this troubleshooting, that’s really helped us along.

I’m glad you’ve made some progress here, it looks like we’re really close to getting things back to normal. I definitely think this was a matter of cleaning and adjusting tension, and I think the last step in our process is still just a bit more tension tweaking on that belt under the laser arm.

Comparing our sample photo to yours, I spot two things:

1) The belt doesn’t appear to be ‘hugging’ the pulley quite as tightly

2)The position of the pulley, it looks like the pulley could be pushed further to the right (when viewed from the front of the printer). Though in this second case, this could just be a matter of the angle of the photo.

Our sample

Your photo:

Would you mind giving it one last attempt for me to see if you can get that pulley over any farther? Here’s our guide for adjusting this tension, just for reference.

If that doesn’t want to adjust further it’s possible that this belt has just relaxed and stretched a bit, in which case we can send a new belt your way and that should help.

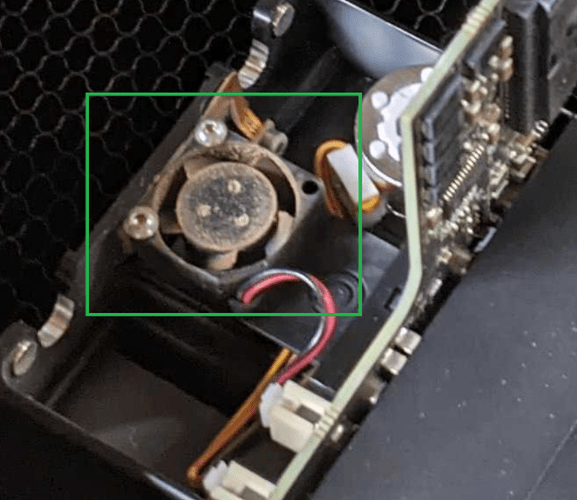

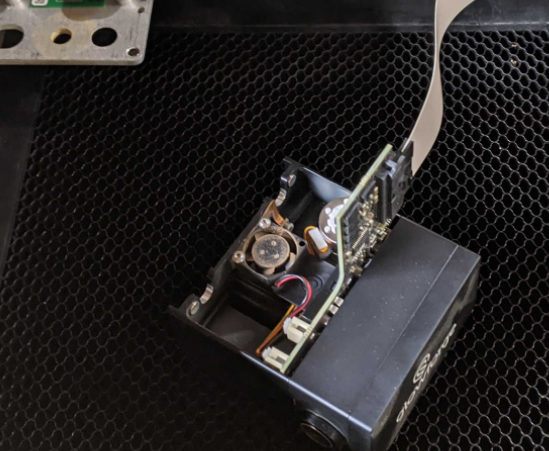

That was was what we did last night me pushed it as far as it would go. But now we are back to our original problem before all the belt stuff which is hot to get the ash build up out of the small sensor as well. This past couple of weeks dealing with this adjusting and tests , garbaging supplies has me hating the machine. I just want it to go back to where it was before when it worked smoothly and you waisted maybe a stamp or two refining the design. It has me so stressed out. Thanks for sticking with it and trying to help. What I really need is a center in Canada vI can just ship it to for them to make all these adjustment would be so awesome

I’m glad to hear you were able to get that tightened back up @bclmtaylor that’s great!

Regarding this buildup, one other thing we could check, just to be sure, is your purge fan. If this isn’t working right it could prevent debris from clearing out of this area properly. I apologize for the frustrations and thanks for your patience as we work through this together.

Turn the Glowforge off

-

Leaving the head plugged in, remove it from carriage plate, set on crumb tray

(Be sure to leave the lid open)

Turn the Glowforge on

-

Inspect: Purge fan should spin when Glowforge is on

That it. Just make that fan is spinning.

Turn off printer

Place the head back on the carriage plate

Turn the Glowforge back on

Let me know what you find!

All good. We made sure to clean both of those fans with compressed air and even a toothbrush

Hi @bclmtaylor thanks for the quick follow up. Just to be clear, are you still noticing issues with the print results after tightening and cleaning all the parts Mike mentioned earlier? I was reviewing the current log files, along with the previous photos and troubleshooting to review the effect of the ash noticed in the small sensor. From everything reviewed, there is nothing I’m seeing related to the focuser failing or contributing to print issues, but wanted to verify the current status of everything that you’re noticing to make sure we can fully address.

In the meantime, I have noted that concern, along with the other issue with the carriage belt. Since there was some cleaning mentioned and the pulley adjusted, it can help to clarify the current state of prints or am updated Gift of Good Measure as well.

We’ve done some more cleaning and tightened all the belts and it does appear to be printing better. The text in the measurement tool looks much cleaner. I’ll do some more testing and let you know if we encounter any more problems.

Thanks for your help.

Thanks for all the help. It was much appreciated. It was a frustrating few weeks but I think we are back on track. Was able to successfully cut stamp design again.

Hi @bclmtaylor. Thank you so much for letting us know, and I sincerely appreciate all of your patience with this. I’m happy to hear you’re back up and printing successfully now. I’ll go ahead and close this thread, but please do not hesitate to create a new thread, or write us at support.glowforge.com, if you run into any other trouble. We’ll be here and happy to continue any needed troubleshooting. Happy printing!