We have had a few topics on coin sorters and I was captivated by one with an X-acto knife and knew The Glowforge was perfect for it. After a couple cardboard mockups, I did one out of acrylic and some 3D printed parts. It works great.

Well darn. Even the gif is too big. Will post full video on YouTube when I get a chance to upload with other than mobile device. Out of the country for a while.

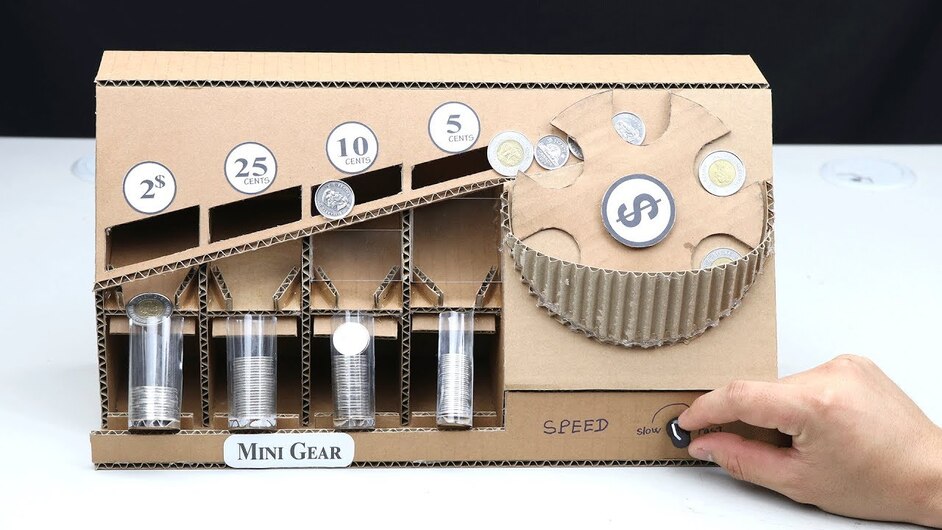

Inspirational YouTube video:

First cardboard test without joins.

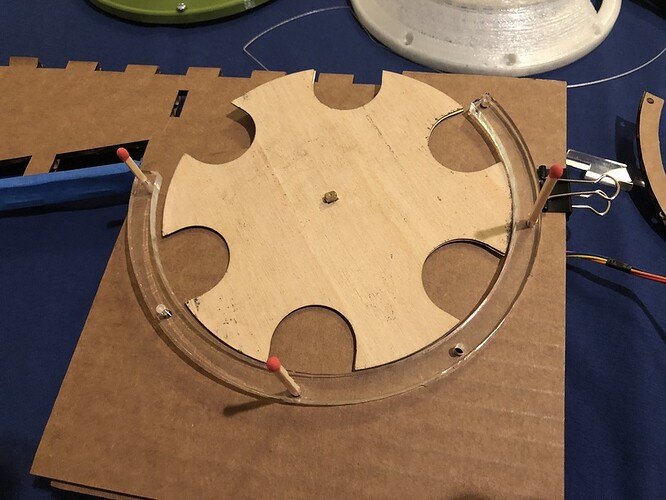

The cardboard worked, but the blade was too thick and it would have smaller coins riding on the top of larger coins and get put into the wrong slot. So I tried chipboard and veneer. Right size, but not stiff enough.

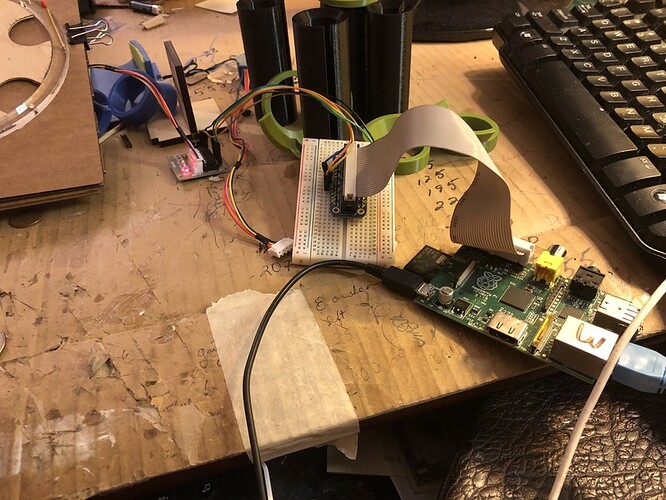

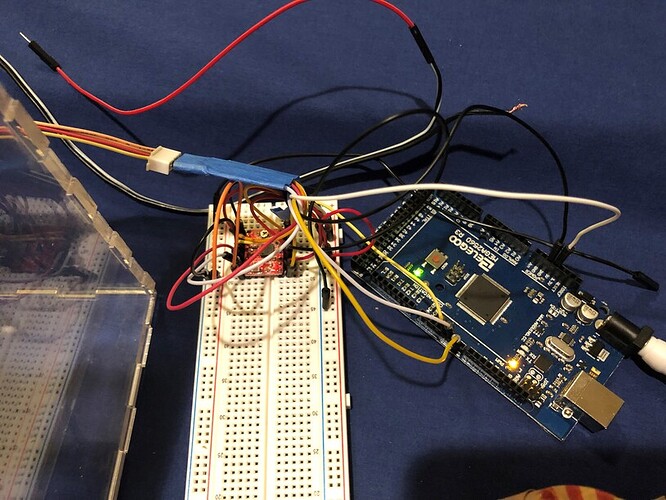

I used a small stepper drive and a raspberry pi to drive it. Worked as proof of concept, but not quite powerful enough.

One of the important features was the trough to put the coins in. Had some ideas for a living hinge, but decided that a 3D printed scoop would be best. The laser and the 3D printer worked great for this part. The acrylic half lid allowed for clear viewing.

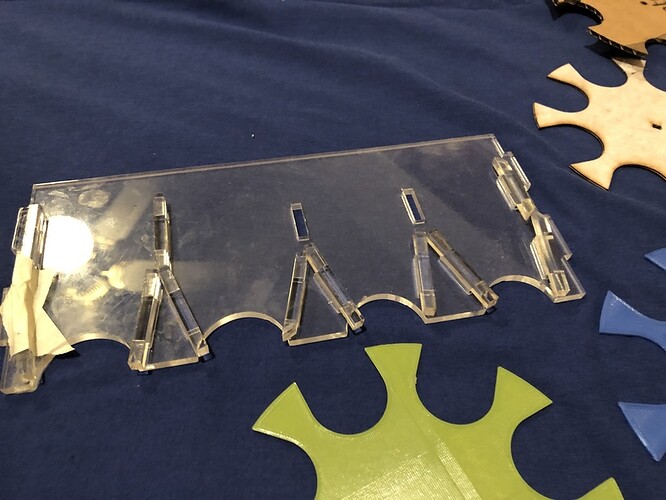

Some of the iterations of the blade.

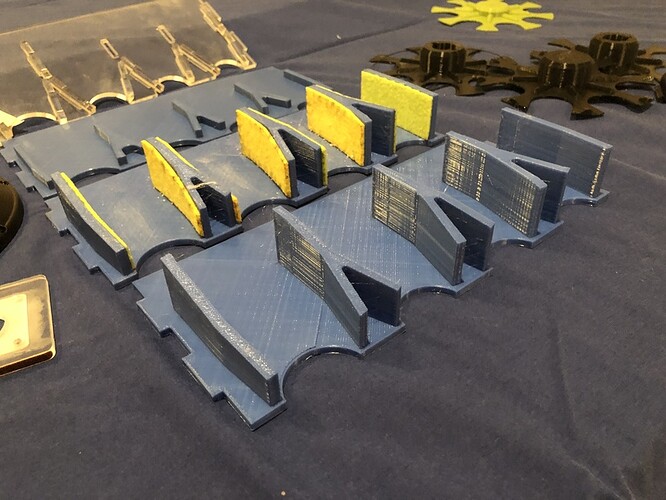

Iterations of the coin holders. I made them so that there is a plinth on the bottom that holds the coins up so that when there are the right amount for a role, it reaches the edge of the chamfer and the edge of the coin wrapper.

The hoods were necessary because the coins really bounced around the ledge after going through the sorting slots.

At first I used a ledge like in the cardboard model, but it really needed bigger sides. I figured that a 3D printed ledge would just be easier but it could be done with the laser just fine.

The felt again was necessary because the coins were really jumping around.

Cutting the felt with the Glowforge was perfect since each was a specific shape.

Initial acrylic mockup of the case.

I ended up using a NEMA 14 stepper that I had taken from an old HP Scanner. Took me a bit to get the motor control right. I finally bought an Arduino starter kit and a couple drivers. I have an ESP32 in mind for final control, if I get to it. Would be interesting to get the control wireless and set some counters up or something. Simplest would be to get a potentiometer and a 555 timer in the circuit so it’s all self contained. The NEMA 14 motor has plenty of torque to manage coins, as long as I don’t load up too much.

I did test sorts with a mix to fill up completely the four rolls. Three times in a row, 1 minutes 37 seconds to 1 minute 55 seconds, perfect sorts.

Scale makes it easy to double check amount.

One of the interesting problems is of course how to attache the blade to the motor shaft. The motor I ended up using had a gear on it that just wasn’t going to come off. Also was the issue of how to print the blade easily. The two parts with a hub and a wheel worked great. Kept tweaking the blade profile to ensure that it kept the coins flowing.

The coin tube holder works great to take them out and put back in.

I just think that anyone making projects could benefit with a laser. The ease of cutting panels and boxes is great.

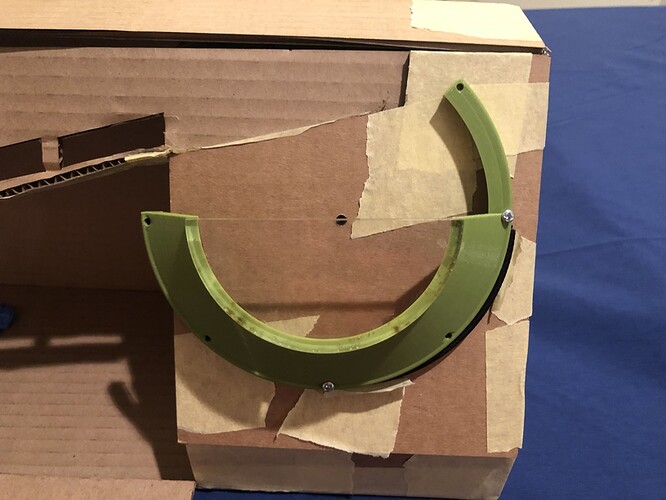

Testing the motor mount inset for the NEMA 14.

The final haul of four and a half years of pocket change dumps.