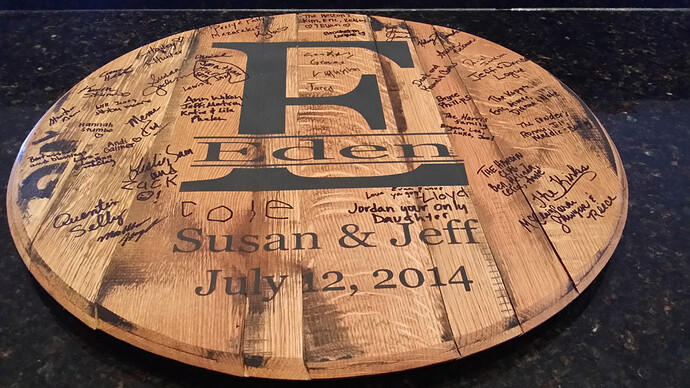

I have someone interested in hiring me to work with the top of a barrel for a wedding piece. This is exciting, but the dimensions of the piece are 21" diameter and 1" thick. Does anyone have experience working with something just a bit too large like this? Is there any way that I could engrave on the piece itself, or should I suggest creating a new piece or set of pieces to be affixed to the top?

How about first considering creating an outer ring, perhaps 1" wide, in sections, where the joining piece, like a ‘bow tie’ shape, is repeated as an score line all the way round, and disguises the joints. This gives you a decorative border that reduces the centre piece for your design to 19".

I assume you have a pro ?

Then create the centre piece using the pass through slot.

Also, it ought to be possible to have a central pin through the honeycomb bed to act as a pivot to rotate the design around, rather than re-position the work piece, but all depends on your design.

Hope that makes sense !

John

As @johnbrooker noted, you’re not going to be able to work with something that is 21 inches in diameter with the Glowforge. You will not be able to physically fit the piece into the machine, even with the pass-through slot.

Check the Tech Specs on the machine:

WORK AREA

Maximum material depth: 18" (455 mm) for Basic and Plus; unlimited for Pro

Maximum material width: 20″ (515 mm)

Cutting area: aprox. 11″ (279 mm) deep and 19.5″ (495 mm) wide

Maximum material height: 2″ (50mm)

Maximum material height with tray: 0.5″ (13mm)

Your best bet is to propose making something to put on top of the barrel if you’re you’re going to use the Glowforge.

You might be able to make stencils or templates with the laser and use some other method to mark the barrel top (paint, flame, router, chisels, etc.). Try a few things as tests just to be sure.

That’s the stated maximum, but has anyone checked to see if it is the actually physical maximum dimensions possible for fitting a piece in and still having it work. I feel like there was a little bit extra on the edges. I’ve been seperate from my forge or I’d check

People have already had the gantry coming of the rails reported to be caused by a workpiece up on the metal edge of the crumb tray, so I don’t think there’s much wiggle room.

The OP said the piece was 1" thick, so he wouldn’t have the crumb tray in place. That’s good to know though  come to think of it, the pass through wouldn’t be large enough to fit the piece, and I highly doubt there is enough space front to back for 21"

come to think of it, the pass through wouldn’t be large enough to fit the piece, and I highly doubt there is enough space front to back for 21"

Ooops, you’re right. Missed that.

I see you and John fit the rest of the pieces together between yourselves.

He could cut the top into either 2 (would fit, but wouldn’t be able to laze full area even then) or 3 120 deg pieces or more, smaller pieces and do something, but that would probably defeat the purpose.

Cutting templates and using a wood burning tool (I can’t remember, do they have a cooler name?) or even just trying a bottle of NAPP gas and flame kissing it might be cool. I guess don’t try that in the house or garage though  (and don’t blame me if applying flame to wood starts a fire!)

(and don’t blame me if applying flame to wood starts a fire!)

I’d best get your contact info, as my lawyer might be calling. . .

Genuine barrel heads are cut from scraps with straight edges, often just pinned together (no glue), just like the staves.

If you remove the head, you might be able to break it down into parts that fit, then reassemble when done.

Have you considered a stencil? You can do one for paint or a router.