I’ve grumbled several times about the steep learning curve of Fusion 360, but it keeps drawing me back, like Don Quixote to a windmill. So I present to you the Bendbox (aka the “Box-on-a-Diet”), which represents my stab at learning the sheet metal tools and the colorific plugin for the Glowforge:

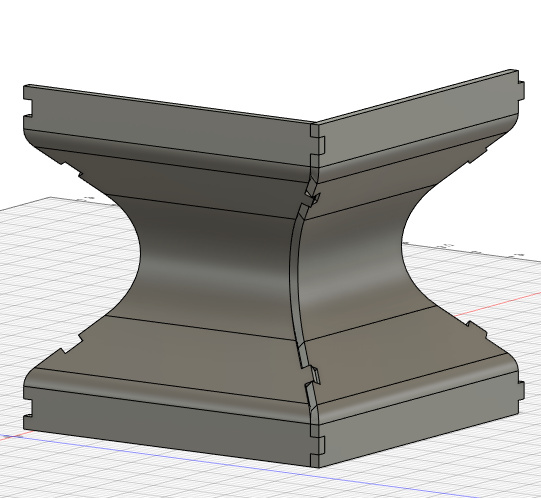

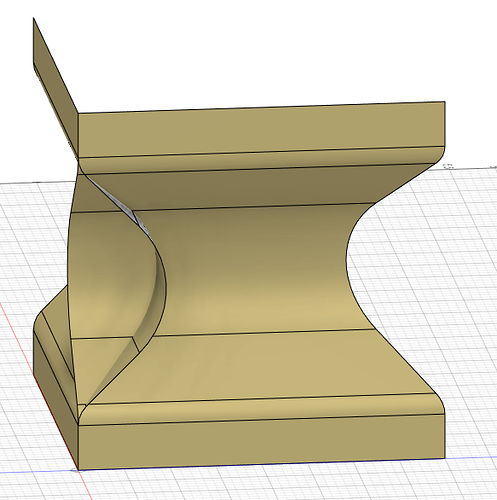

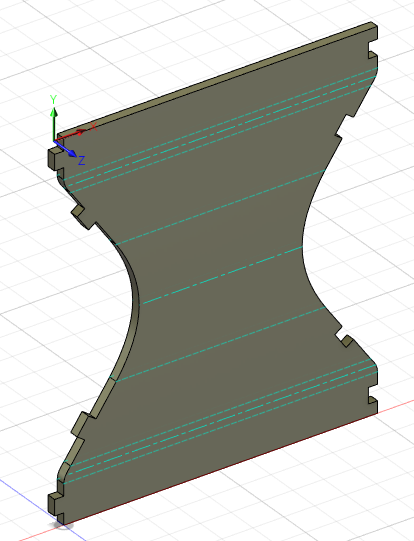

I started with a “simple” sketch of the profile of one side. (It was simple in appearance, but fiddling with properly constraining the relationship between curves was fiddly.) Next I swept a surface and used rotated copies as snipping tools to carve the side into its hourglass shape:

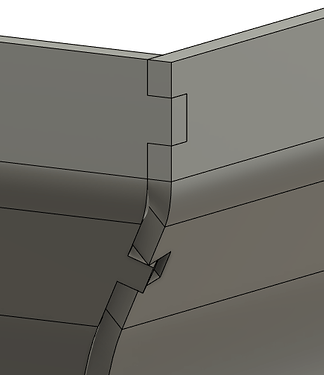

The top and bottom tabs were easy enough, but the curved tabs are tricky. Not only do the sides meet there at a non-square angle, but one side curves over the edge of the other:

This is where Fusion 360 really shines… I could make modifications to the sketch and instantly see them reflected in the rendering of the 3D corner as they were propagated forward through the entire construction history. So cool! A quick interference check let me know exactly when I had things adjusted properly. (My Inkscape workflow would have required lots of tricky math or, more likely, a series of prototypes as I honed in on the right values.)

Finally I converted the thickened side into a sheet metal part and generated an unfolded view:

I used the colorific plugin to export an svg and experimented with living hinges in Inkscape. (This is where Fusion 360 comes up short… I was not going to fiddle with cutting profiles with that many cuts, as that part of the system is still very manual.

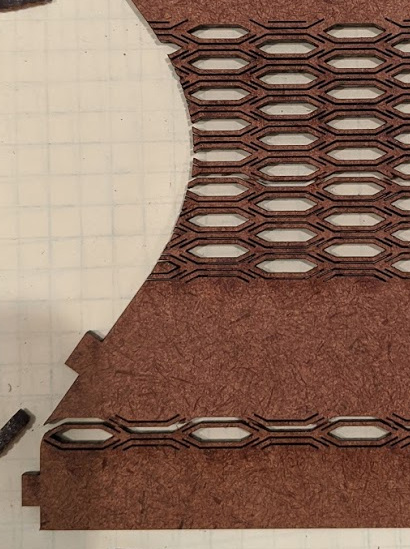

My first attempt was a hexagonal living hinge (from the Obrary swatches), but it was far too fragile even for my gentler bend radius:

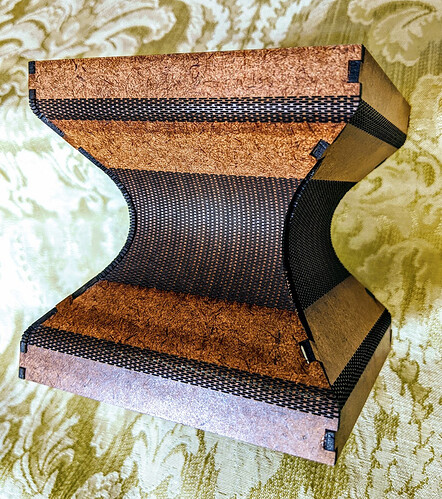

So instead I made a fine mesh of offset dashes for maximum bend-ability. (My prototyping material of choice is Home Depot 1/8" chipboard, not a high-flex material.) Here’s the mesh mid-burn (gotta love that burn ordering algorithm):

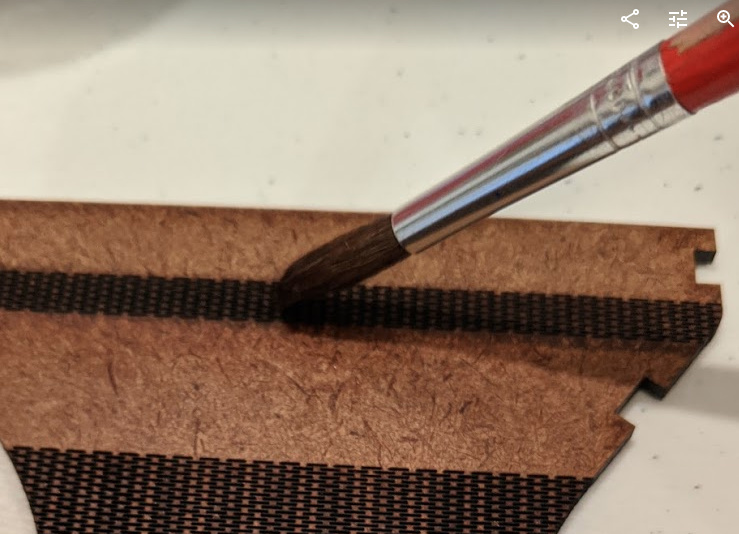

Next some alcohol on the tight bends:

And then into the jig (a Fusion 360 quickie that snaps together at top and bottom):

And then assembly:

And that’s about it! No adjustments were necessary, everything fit perfectly just as Fusion 360 showed:

It’s definitely a nice tool to have in the arsenal!

I had visions of a box with a colonnade around the outside. Kinda like a Greek temple.

I had visions of a box with a colonnade around the outside. Kinda like a Greek temple.