this makes sense to me. maybe even giving some breaks in between passes to allow things to cool off would be a good idea.

It is worth a try, but sadly I doubt that frame will help much. The effect you are seeing is going to be very strong. you would need to be able to clamp the metal down on a really rigid surface and basically have the clamps be strong enough to be able to stretch the metal. As you already guessed, you are getting localized heating and the Titanium is expanding and causing the warping. The real problem is that Ti just doesn’t conduct very well so it builds up in one spot.

The general suggestion to reduce the amount of heat is the way to go. Can you reorganize your print so that beam doesn’t stay in one area for a long time?

I am trying to think of what else might help and one possibility is to put a “heat sink” of some sort behind the Ti. This might also change the heat coloring though…

It is going to sound crazy, but if you have an Aluminum cookie/baking tray that will fit in the GF that might help. The thicker the better. Tape the Ti sheet down on the tray so it is in good contact. Hopefully that will help pull the heat out of the Ti and reduce the warping.

Thank you so much for your input…it’s especially valuable coming from you.

• “Can you reorganize your print so that beam doesn’t stay in one area for a long time?” I do now have every element in the file designated in different colors, so I could alternate which part of the file I do, if that would help. Also, I intend on doing some more tests…same power, but higher speeds, lower LPI, and multiple passes…allowing some cool down time in between.

• “Aluminum cookie/baking tray that will fit in the GF …” Actually, I think I do! I have a small sized one in our RV that might fit. I’ll check that out.

Great to get some additional ideas on how to do this. It may end up being a failure, but at least it won’t be without giving it a real hard try.

I also just realized that I can also utilize the ability to pause the GF during the print to alleviate the heat buildup.

Wow…I think this print may take a very, very long time to complete…

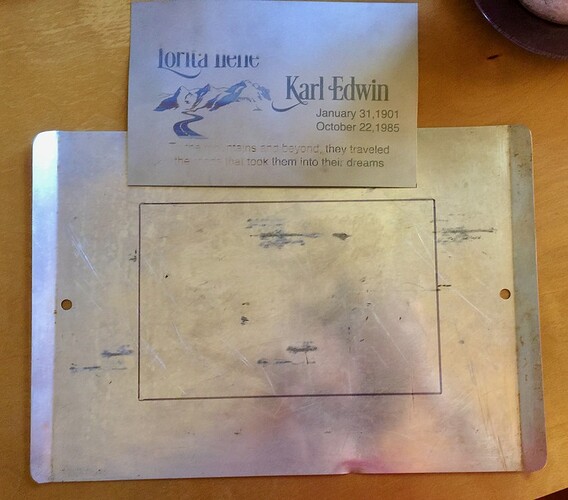

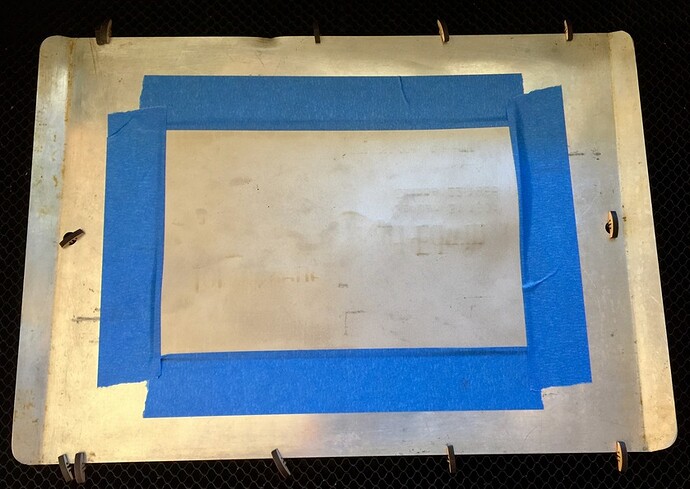

Not going to start my testing until tomorrow as it’s late in the day and the temp is a bit high here today…but, I’m ready to roll tomorrow. Found my rinky dink little cookie sheet (10" x 14" aluminum) out in our RV and have sacrificed it for the sake of my project. I still have to be able to put my sheet of Ti squarely in the GF to be able to align my file, so I drew a correct size rectangle with a Sharpie of where to place the sheet.

I taped the piece of Ti down and then pinned down the baking sheet with hold down pins. Quite handy how I got two extra anchor points with those two holes on each end! This is the back of the bent-up piece and you can see on the right side where the tape is buckled…but, I got it down flat as best I could. Hopefully, with the new piece of Ti, it will be flatter.

I can’t take up a lot of area with the tape on the Ti itself…with only about a 1/8" available margin and I still have to be able to align everything. This is beginning to make me nervous!

Hope it works really well!

Thank you!

That’s gotta work. Good luck.

You might want to try using Gorilla Duct Tape - it’s a way stronger bond than the blue tape. I’m not sure the blue tape will hold the Ti down.

Or drill some more holes in the aluminum sheet (if you really are okay sacrificing it) and use more hold down pins.

But then this whole thing has been a fascinating experiment to watch develop.

I agree about the tape. It’s going to take something much stronger than blue. I added a piece of duct tape over the one bent spot up on the right and even that is buckling. But, I’m almost finished testing for today and so far it’s all held just fine. At least the new piece of Ti won’t come being already warped like my test piece. So far, the baking sheet with hold downs is steadfast. I’m leaving it all set up until I’m satisfied with everything…but, then the whole outcome is also going to be telling when I turn the test piece over and see what happened on the other side…as well as seeing if it’s any worse warped than when I started.

Question for you…I’ve been letting it cool down for about 5 min. between each pass. It’s so arbitrary…deciding how long to do that…any suggestions?

Do you have one of those infrared thermometers (the kind you point at something and it shoots a laser at it to tell the temp)? You could use that through the lid to see what temp it was hitting. Then see if 10 minutes is better or if it’s okay with 5 up until say the 4th pass and then see that it’s not cooling off so you add time then instead of arbitrarily for each pass.

Me too, I have no advice to offer, but I very much am looking forward to how this turns out.

Just a thought, but I’ve never had much luck reading off bare metal, and the lid is designed to block IR radiation.

Same wavelengths? I’d have to try for sure but then I’d need to get something hot in the GF first. I went looking for the laser thermometer and actually found it down with the GF. I must have used it for taking the temp of something GF related but for the life of me I can’t recall what.

Just microwaved an empty meal carton. Measured 140ºF. Propped it up so it was just below the lid. Probe read ambient temp of machine.

bummer

I tried it as soon as I could just open the lid…just got an error code