The other day I saw http://blackcatcutters.com/proddetail.asp?prod=CBeamCNCkitMechanicalBundle

and drooled a bit. But being new to, I guess Maker culture, I can’t tell if it is a good deal.

I mean you have to assemble it obviously which could be painful. But I can’t even tell if it has all the parts needed, like the actual machining tool itself.

It even has a “not included in this bundle” section which I have not even looked at how expensive those parts are.

It just looks so fun though

1 Like

seems to be all the hardware but not the electronics and electrical components, no drivers, as you noted no machining tool, no power supply which should be easier to source than GF. could be a long ride from that to a working machine.

1 Like

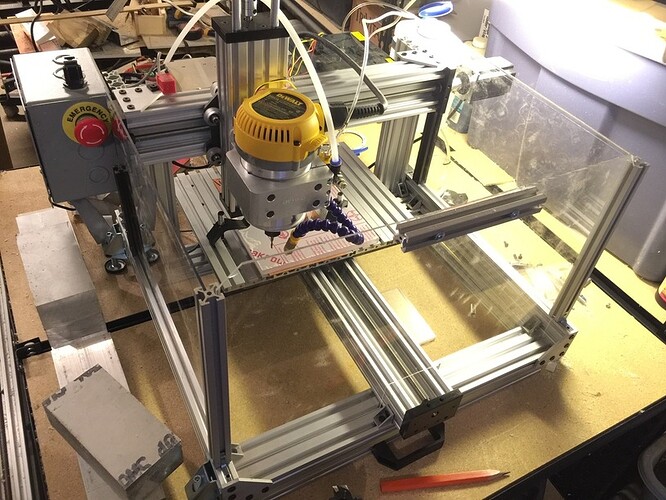

That’s the same unit I built my machine off from.

I am assuming you are in the UK as they are a UK supplier.

As stated above- This kit is the mechanicals only. You’d have to source your own steppers, drivers and motion controller (GRBL, Smoothie, TinyG or TinyG2, MachineKit/LinuxCNC or Mach3/4) and a spindle.

The base unit is very good. Pretty easy to assembly as the base unit is pretty small.

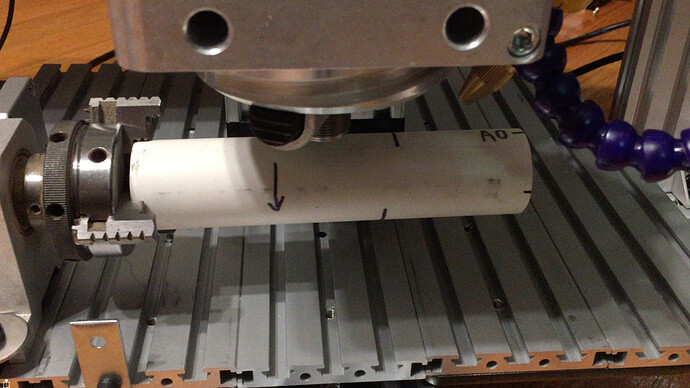

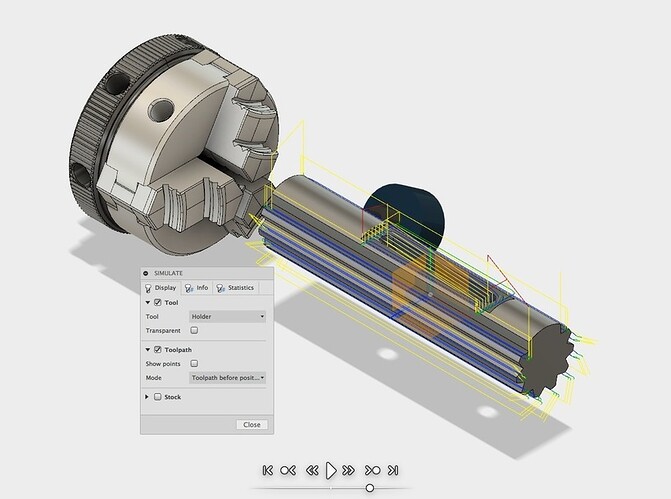

But in my case I needed to add some heft to handle thicker aluminum stock. Plus I wanted to also use a rotary axis.

6 Likes

U.S. actually. Didn’t see that blackcat is U.K. anywhere but I could be wrong.

I am immensely jealous of your setup

http://blackcatcutters.com/about.asp

Thanks. I am really happy with that setup.

2 Likes

I built the C-Beam machine, like @karaelena, from a kit supplied by OpenBuilds, OpenBuilds C-Beam Machine - OpenBuilds Part Store I had no problems following the YouTube video produced by Mark Carew of OpenBuilds https://youtu.be/HVR8pABCHXI.

I did have to buy a controller, steppers, and power supply, but that gives you the option of choosing your own if you are familiar with a different control board or already have a power supply or steppers.

The machine works well, my only problem is that I have a Makita trimming router which is a different body diameter to the Bosch Colt and despite shimming the mount it has some “slop” I need to get rid of. I have not been able to machine aluminium successfully yet. My first project was to machine a router mounting clamp to suit the Makita … yeah, no … didn’t work. I’m keeping the broken mills and mangled aluminium to remind me of the problem.

The machine works well with wood, I’m even considering trying to make a router mounting bracket out of hardwood. I would also follow @karaelena and install an aluminium base plate.

I should say that I bought the machine to introduce me to 3D modelling, G-Code and CNC while I was waiting for the GF. It has certainly done that!

1 Like

Hi @karaelena, Your router clamp looks just the ticket, do you mind telling me where you got it and the base?

I plasma cut the plate and had the mount made at my buddies race shop. Also that mount is for a DW618.

1 Like