I love it! Thanks for experimenting for the rest of us!

Sir, you need to convert to Stubb’s. It will change your life.

but… how did you measure the height of the caliper?

lol, awesome test, great results!

@rubbersoul79’s wet paper towel idea.

Under X60 it looks like an oxide deposit on the surface. Very tough, and scratching with a tool burnishes it rather than removing it.

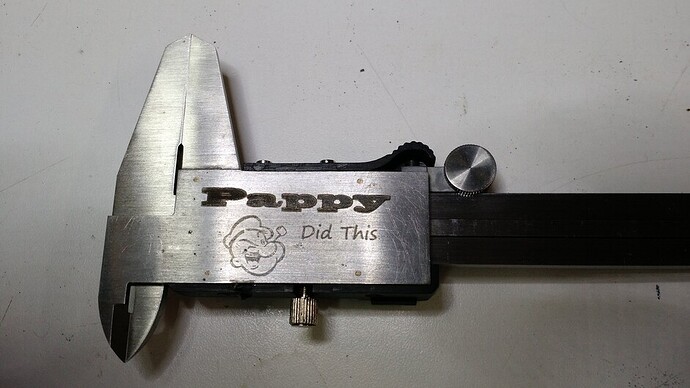

This is the first test, second got a lot darker going slower.

Thank you for the great share!

I used another mechanical caliper to gauge the highest profile of the other, locked it down and used the subject caliper to measure the value. Then with tray removed, 3/4" thick block, a 1/4" and an 1/8" shim I told the laser it was looking at 1/8 or .125 focus.

In the same class as hand grenades … close enough.

If you want support, you have to use the good stuff.

Frank’s RedHot

The guy in the YouTube video is using that… I found it funny.

But of course.

Thanks. Seems to work reasonably well. Old used razor blade with white vinegar soaked paper towel, no mustard. Haven’t experimented with settings. One and only test.

Though you can see that the rest of the un-coated razor blade didn’t appreciate the vinegar and stained it.

(Guess that just proves that razor blades aren’t made from stainless steel.)

Just a thought, as I’m not in a position to try it, at the moment.

Could you turn the vinegar(your choice) into a gel, so that a brush coating would replace the paper towel ?

I have some distant memory that suggests that gels and acidic conditions are not compatible, but whatever…

There is one example where gelling requires acidic conditions, making fruit jam. The acid level must be high enough or it will not gel properly. Of course if it’s too high it probably doesn’t set either.

There is way too much awesome in this thread.  When I saw the price of Ceramark, I expected to do marking sparingly, but tons of ideas are back on the table.

When I saw the price of Ceramark, I expected to do marking sparingly, but tons of ideas are back on the table.

I got my golden email two days ago, but I won’t have a physical address to ship it to until August.

So, if I might ask: has anyone tried this on glass or ceramic?

Have you tried your experiment without the paper towel?

I repeated your experiment on a piece of machined 304 Stainless Steel and

I obtained identical results with both vinegar and water soaked paper towel.

I also tried the ABI Tape masking tape like that on the proof grade materials.

That seemed to work better when I burnished it. When I decreased the speed,

the marking was even darker. I obtained the best results with no additional material on the surface and a speed of 130. Other Stainless alloys may give different results.

Your meaning depends on how I parse your post. Clarity request.

Did you mean that you used mustard and then got identical results with overlaying water or vinegar soaked paper towels? Or something different?

The reason I am confused is it might read you didn’t use mustard but used a water soaked towel and got the same marking as a vinegar towel.

For clarity on my post, (now edited), I only used a white vinegar soaked paper towel with no mustard or anything else.

That is correct. No mustard was used in my experiment. Only paper towel with vinegar or water. Both gave the same color density of marking. With the alloy that i tested, the clean metal surface gave the best color density. Presumably, The paper and liquid blocked the heating effect for the period of time the laser impinged upon the metal surface.

Are you leaving the paper towel on the metal and then etching through the paper towel?

So now we’re saying that water alone causes an effect on stainless steel?! Isn’t that kind of like saying “using nothing will have the same effect?” I mean, I’d think any water would be completely evaporated instantly.

Acidic paper ?

Read on. On the 304 alloy that I tested, The best marking was obtained with the bare metal surface, i.e. nothing between the metal and the laser beam.

My original intention was to try other organic acids that are not as volatile as acetic acid, e.g. oxalic and citric acids. Then one could use higher concentrations without worrying about corrosion from acetic acid vapors. If the acid was necessary for darkening the metal surface, then a higher concentration would likely created a stronger effect. Before doing that, one has to confirm the null solution where no effect is expected, so paper towel with distilled water was used. Same effect as with 5% acetic acid (vinegar) so no reason to continue. The 304 alloy is not as corrosion resistant as the 316 alloy, but it is less expensive. I have some 316 bar stock, but it has not been machined so it is quite rough and would not be a good test. If others have only seen the darkening with tvinegar, then the alloy used would be of interest. The history of how the metal was worked can also affect the surface chemistry of the piece.

Jeff Forbes, Ph.D. (Physical Chemistry), AB3YM