The only thing that is always in the back of my mind is. What about if the company goes bankruptcy? Then I would have 2 expensive paper weight machines because of the online UI. Or what about if the internet stops working in the middle of a very important job with a tight deadline. That is the ONLY thing that I wish GF had. A desktop software

… and in the meantime, you are investing substantially less to get the business going.

If you need that level of assurance, then you need to up the investment significantly.

Right, I guess that is the give or take part of the whole deal. And that is why I ended up buying it in the first place. It is the best reward/value I could find. That’s why I will end up buying a second one. I just wish they didn’t had a month waiting list and affirm for some reason is not financing the Basic model anymore

You want to cut metal with a laser, CO2 isn’t the way to go. You want a fiber laser. Even a relatively small wattage with the right frequency can cut metal. 30W fiber can cut 0.2mm steel… has no trouble cutting 0.4mm aluminum and copper.

Prices on a 30W fiber can be as “cheap” as 4 grand, give or take.

Absolutely no sense in trying to cut metal with a CO2 laser. Not what it’s meant for and you pay through the nose to get one to do it.

Let me ask you this question. Are you doing a lot of back to back projects? Are you using materials other than proof grade? Are you doing cuts or engraves? Are there a ton of cuts in an individual run?

I am asking this question because the time you lose from a ‘slow’ cut may not be your real time sink. If you are using your glowforge to make very large items, like a desk organizer, your time sink may actually be the time it takes to switch between operations. If your making name tags, your time sink is the speed of the laser cutter.

I think to better assist, what kind of projects are you wanting to do with the new machine. Lets start from the beginning and get the requirements. Tell us what the machine absolutely has to do and what are the nice to haves.

The short answer is that you may not be looking for a laser platform. We may be trying to put a square peg in a round hole here.

I am making tokens about 1.5"-2" diameter, So I am engraving and cutting, I can fit about 15-20 tokens per run. So there are between 15-20 cuts and 15-20 engravings with graphics and wording

I have the basic GF but sometimes it is not up to the game because randomly when it cuts after engraving, the cuts are off or shifted to the side even tho it’s the same artwork. So that is a little frustrating. And I am not touching the material until is done, it happens randomly at random spots in the same run. I clean the lenses and machine constantly and use the pins to hold material in place. And yet, I want/need another machine

I use it pretty much non stop all the time!

Have you heard of Boss Laser? I’ve done a little research on them and there reviews seem pretty good and the service seems good as well. I think there based out of Florida, and you can get a 100W laser with a 15x29" bed for about $9k. Just a thought. They also have a model that is called the HP series that can do everything a normal laser does, but it can also cut thin steel up to 18g(1.02mm). It’s more expensive at about $15K and it has a 24x36" laser bed and is 150W. But, as someone stated above in order to cut steel with the HP series it needs to be hooked up to an O2 tank and they can help with that.

I will look those up. Seems like a good deal for what it does. But, the metal cutting is just a thought I have for future projects. Not something immediate. What I really want is a “faster glowforge” that can engrave and cut plastic faster but I guess those come with a high price tag

The Glowforge is an awesome small batch manufacturing platform. I am going to break this down into a couple of different scenarios.

A Coupe of varieties

If you have only a couple of varieties of tokens, your best option would probably be injection molds. These are awesome little machines and if you are able to make your own, you can get one of your own pretty cheap.

Your second option would be a SLA 3-D Printer. This will probably make your cost per unit more expensive. But an advantage here is that your print time is more based on the height of the items, not the width or depth. This is because a SLA printer basically uses screen to print each layer. So any entire layer is printed at once and pulled out of the resin.

Each batch of tokens is custom

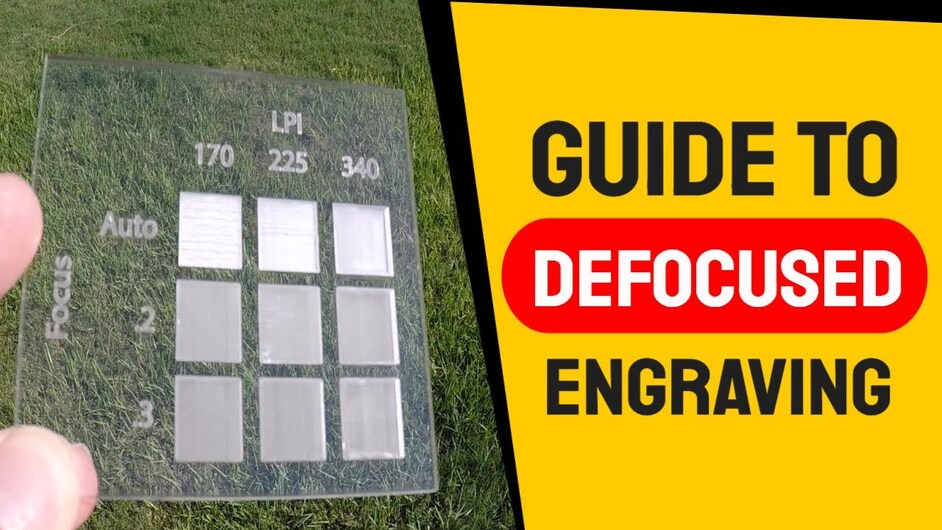

Unfortunately you probably don’t have alot of options here. You might want to look Atlanta Maker’s most recent video post on defocused engraving.

You can also get additional machines. These can be high wattage lasers or additional Glowforge basics. Don’t forget to deduct the purchases on your taxes at the end of the year if you have a business from this.

I want Metal too

This is where things might get a little interesting.

Using the Glowforge and a wax medium, you could create a lost wax casting and use pretty much any metal you want. The investment here would involve getting a kiln needed to heat the metal and potentially your plaster mold. If you are doing jewelry grade stuff you might want to buy a spring loaded centrifuge that allows you to load your molds into. Not everyone I have seen uses these but a lot of the jewelers probably do and the ones I know do.

You can also use a Wazer. The Wazer is about $8,000 and is very similar in concept to a laser cutter but uses high pressure water to cut and engrave on pretty much any surface. The highest end package is $10,000 and includes additional cut beds and plenty of abrasive to start with. I would probably say this is like the Glowforge of what jet cutters or at least that is the way it feels. I have yet to use one of these but I am very interested.

You can use a CNC like a X-Carve and Shapeoko or even a higher end version that could operate faster. On an X-Carve, the CNC I own, metal is slow as other posters have mentioned but other materials are pretty fast. The CNC would also be capable of creating wax representations and you could then also create lost wax casting.

You could use a fiber laser but I am not sure you are going to get really good detail. I have never used a fiber laser and those are way out of my price range.

You might be able to use a plasma table but I am pretty sure you can’t get the detail you would probably want to see.

How I would do it

First, the quick hit to try and alleviate immediate bottle necks I would purchase another Glowforge. I would build, if I didn’t already have it, a bench that could accommodate an upper Glowforge and a lower Glowforge in a stacked fashion.

Second, I might try buying acrylic rods in the diameter I most frequently used and setup some sort of automated cutting device that would cut the tokens in the right width. Then just use the already cut pieces of rod for the engraving portion. I would probably use a piece of cardboard to make a jig that I just slip the tokens in and out of.

Third, I would probably start going down the path of building my own laser cutter based on the plans from Further Fabrication. I would probably change his design to accommodate 4x8 sheets of materials so that I could do larger runs and open up the sourcing of my material. This could also lower my loses from scrap material. I would also probably upgrade the laser to an 80 or 100 watt on this one for the faster through put. Basically, make this machine the primary machine for making tokens. This would probably put the cost of this laser cutter in the range of $4-$6k. I might even make the bed on the bottom slanted to allow the coins to just drop out and straight into a box or something for me.

Fourth if I wanted to offer metal coins I would probably start playing with wax on my Glowforge. You could probably get a dozen or so tokens pretty easily into a single casting. To me this seems to offer the widest variety of options including metal type along with a fairly low barrier to entry. I could also immediately start playing with lost wax casting by machining coins on the CNC while I tried to fine tune things on the Glowforge.

If you don’t have a whole lot of job shop or parts manufacturing experience, or haven’t studied manufacturing, perhaps a trade show might give you a sense of what is out there.

I went to one of these exhibitions a few years back and was blown away by all the things I had no idea were being done. Not sure how many of these are going to have in person meet ups in the coming year, but it is worth a chance.

In Germany there is the Hannover exhibition and trade show center. It is absolutely the coolest thing in the world. Industries get together there for some of the biggest shows in the world. I went to an agricultural trade show and will never forget the automatic egg boiler/peeler machine. they gave out free hard boiled eggs at that exhibit. The German YouTubers go to some of these trade shows and give a glimpse into some of the new tech that is out there.

you know. if you are looking for lower interest financing. keep an eye out for transfer a balance card offer.

The wax option would be my IDEAL scenario. Creating a was mold then turning that into metal would be AMAZING. I am not sure how long it would take for each coin to get done and how much room/space I need (I have a home office) but that would be my dream product because right now I just offer plastic coins but metal ones would be the real deal!!!

Take a look at the video below. This seems to be taught by a real jewelers school.

Now when you get to the wax casting part, that is where the Glowforge could step in. I might try to purchase some jewelers wax and try engraving an cutting it on the Glowforge.

I am in the middle of moving house right now and have been told by the wife, no new purchases before we move. Once I get re-established I was planning to do some testing here.

The setup cost is probably a couple of grand to purchase the equipment and there is also additional time to make each one.

This just occurred to me. The other method might be one with epoxy. If you want to stay in the realm of plastic and low cost, you could also make a sample token out of acrylic and use silicone to make a mold. This really only works if you are doing larger quantities of a specific kind of token.

Also, take a look at this video on using silicone to make a pewter casting. Apparently, they were able to get a low melting point metal to cast in their high temp silicone. This means you might be able to make metal tokens without too much in tooling.

The only bad thing is you cant do beveled edges with the glowforge

Have you tried using gray scale engraving with the setting set to vary power? I know it created something similar to a bevel when I did a picture for someone.

You should really take a search around the forum ![]()

no but that sounds very interesting!!!

To quadruple your cutting speed, simply buy 3 more Glowforges and keep them all running in parallel.

Try getting a new credit card with one year free interest. Then, immediately after placing your order, CUT IT UP!

Bonus points if you choose a credit card that doubles warranties.