I am wondering if there is anything in particular or specific I would need to know about purchasing a used air filter from another gf owner. I have to vent outside in the winter time here in upstate NY and would rather not have to vent outside if possible. I am curious to know if there are any other possible options to look into instead of the gf filter being the cost of the filter cartridge itself is $250. Any help would be great!!

The first thing I’d ask besides “does the thing work” is how “much use has the current filter cartridge had and what have you been cutting with it?”

Just a few hours of draft board cutting engraving will completely fill a filter, but with acrylic or leather it could be months.

There are a bunch of threads on here about adding pre-filters to extend the life of the  filter. Basically fitting a room air filter pre-filter in the box to catch more bits of debris. Definitely do that - but if you have the ability to vent outside, you should definitely vent outside! The other option is to budget $250 somewhere between monthly and quarterly because all laser (not just

filter. Basically fitting a room air filter pre-filter in the box to catch more bits of debris. Definitely do that - but if you have the ability to vent outside, you should definitely vent outside! The other option is to budget $250 somewhere between monthly and quarterly because all laser (not just  ) filters fill up fast and are expensive!

) filters fill up fast and are expensive!

Thanks for the reply. I had seen this on Amazon and it caught my eye.

VEVOR Pure Air Fume 80W Smoke Air Purifer 110V Fume Extractor 180m³/H Smoke Purifier Absorber Remover for CNC Laser Engraving Machine(110V) https://www.amazon.com/dp/B08FRKFTY5/ref=cm_sw_r_cp_api_glt_fabc_ATCVZYVWME8N854VKWQP

Not sure how it would work out though. It looks similar to the gf filter.

Will not be enough volume. If my arithmetic is correct, you will need more than double that at a minimum as the volume will drop as the filters fill. 180 m3/hr is 106 CFM and Glowforge needs at least 200CFM even going out the window. The Blu-Dri is 500 cfm max so is able to drop a lot before nearing 200cfm.

So how would that hook up to the hose? In the pictures it doesn’t show a spot to do so.

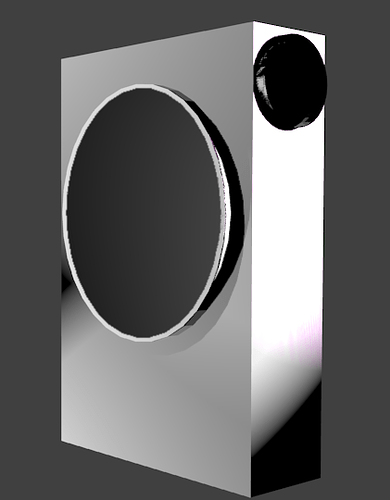

That is the biggest down side. I designed a box to sit in front of the machine with a 12"hole between box and filter, and a 4" hole to the side with a V-8 bottle cylinder epoxied into the side …

The V-8 trick-

And the box design…

Is there something that’s comparable to yours? What does your box look like on the inside? I apologize for the questions. Just looking to get somewhat of an idea of what I would need to be sufficient.

Any kind of filter is a last-case resort.

The GF filter is an absolute bargain compared to any commercial filter suitable for this kind of use. There is a very good reason the cartridge is that size. GF initially wanted a filter unit that sat directly underneath the machine. Technically, or at least financially, unachievable.

Depending on your materials, it could end up costing you $10-20 per hour of use. You can literally fill a cartridge in a day, if you’re cutting MDF/ProofGrade Draftboard/MDF-core plywood.

There’s no way around it. It’s suitable for people with no other venting option who use their machine very little - and with deep pockets to buy those cartridges. GF probably isn’t even making a profit on them.

It is just an empty simple box with a big hole and a small one where they show in the image however you might cobble it together. It could even leak some as it would only leak going in. I had many other designs but that is the most practical that could work well.

In terms of cost per cut I think it would be much cheaper. It would also be noisier than the GF filter but not more than the current exhaust fan. When my exhaust fan died and smoked up the entire room the Blu-Dri cleaned it up in minutes just sitting out. The Vivo exhaust fan does well enough in light use at 190 cfm but if cutting something smoky it could not keep up. Since then I have had working exhaust fans and turn them on as needed so I never actually built that box.

Well my current setup is with an affinity fan. It’s a 6” diameter that has a hose connected from the gf to the fan. Then from the fan to the window. I cut a hole in some thick mdf and had a vent screwed into it. The hose then connects to that. I can still get the smell when cutting 1/8” mdf. I would assume that will always be with mdf. Would it be beneficial to have a setup like the Blu-Dri on the side? I’m only really looking to vent to the outside in the summer not so much in the winter if I can get away with it. By the looks of this discussion it’s not too promising.

There will always be some smells. Since I already have the Blu-Dri I put it to work whenever I am annoyed by the smells (or dusty air). That includes popcorn smells and other smells from the kitchen as well as when using the power sander etc. What goes into the Blu-Dri does not plug up the AC ![]()

If you can seal in the window outlet and have louvers that will block air coming the other way. I would just stay with that.

So I would keep the blu-dri all by itself. Then run my normal setup on the gf?

This topic was automatically closed 32 days after the last reply. New replies are no longer allowed.