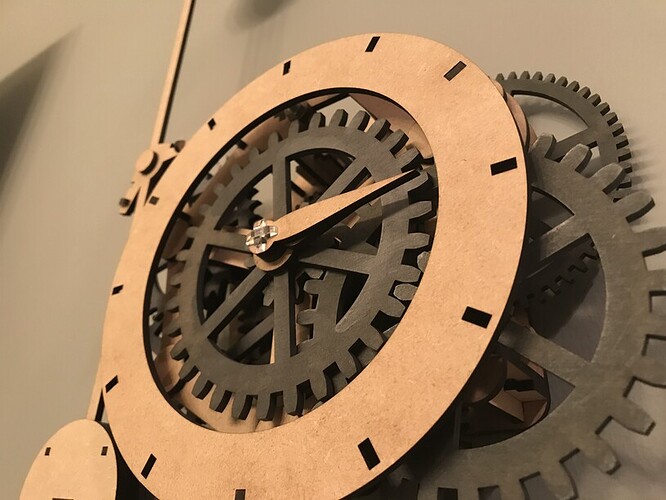

Thanks! It would be nice to do this in some nice hard wood. I would probably change the clock-face too and add some engraved numbers.

Ocooch is cool but they only get so exotic. Wood Database is good to browse and then Google the species to see if anyone is selling it in the size you need.

Good to know…I was just passing along a link to a known supplier to be helpful. I put an order in for some wood from them last night, working on a new project for a friend.

(FYI - my wife has repurposed my “Glowforge time” from focusing on my clock to “Here make a bunch of Christmas ornaments we can give as gifts!”)

That being said, the clock is still running and stopping. I want to make a second one, but need more brass rods (or adjust the design to use some different sized brass rods that I have).

Tis the season

Spent the day yesterday doing the Christmas thing, got everything covered minus one project that I am waiting on a piece of acrylic to come in for. You inspired me Bill to take care of this. Off to the post office today to ship out the bounty of the North…er, um, Glowforge to family and friends.

Still working on ornaments, but if my numbers are right, the clock ran for over 40 hours between rewinds.

I am looking forward to making a new frame using the small bearings (when my  time is my own again…)

time is my own again…)

I have been watching my clock these several days (even though I have not been able to work on it), and I looks like the pendulum is a little off. I think I need to rotate the escapement about 5-10 degrees on the “rod”. I noticed this because the clock seems to run better when it is turned counterclockwise on the wall.

I am just noting changes that want to make when I have time…

- Adjust pendulum/escapement angle

- Add small bearings to minute and hour axles

- Maybe pull the hour gear a millimeter or two away from the minute axle (in an attempt to prevent it from binding so easily)

Good to hear from you, sounds like you had a chance to just let it run and do objective observation this past week. HoHoHo

Just trying to get straight? Was trying to imagine a clock turned counter-clockwise ![]() thinking about leaving the hands still and rotating the numbers

thinking about leaving the hands still and rotating the numbers ![]()

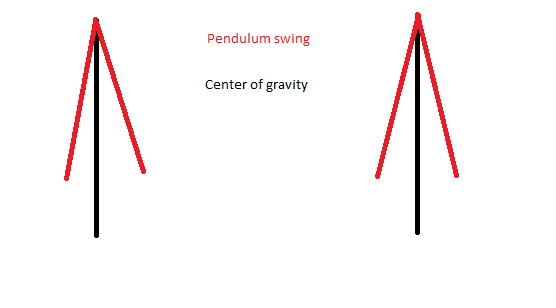

No, it is the balance of the pendulum. I think the pendulum shaft is not straight. So rotating the entire clock changes the effect gravity has on the pendulum.

Something like that.

(I just realized that is bad example because it is leaning the opposite direction. But it is the basic idea of the issue.)

Did you survive the Holidays Bill?

I did. Thanks for asking!

I have about four or five changes I want to make to the clock before trying again, but work is crazy for me right now… I hope to get back to the clock soon!

Yay it’s not just me.

I fear the frame is shifting again, but I am not sure I can do anything about it with my current design…

I will make the planned changes and try to make a second clock. Then I can compare the two more easily. But, if I want to fix the frame issue, I think I will just need a larger frame that can resist the warping. Or maybe I just need a different medium… It might be time to get rid of the draftboard…

Well, my tests with the plywood have been successful after a couple of attempts. So, I have made the adjustments to the frame to have it cut from plywood. I have also made minor adjustments to the angle of the braces, in an attempt to battle the shifting that I think is occuring.

The hour axle position has been slightly adjusted outward, to give the gears a little more room.

And the frame has been adapted to receive the smaller bearings.

I hope to cut the new frame tomorrow (if I can find the time), but I still want to adjust the angle of the pendulum before I cut the rest of the second clock.

Well, I ran into one issue that I didn’t think to test. The kerf on the plywood is wider than with the draftboard. I thought they would be same, but I was mistaken. I may have to make more adjustments than I originally thought…

As I am making the new frame, and designing it to use pressure fit braces, I am realizing that I really should find a way for it be be held together with hardware. Since it should be able to be disassembled in order to do maintenance on the clock.

I am learning that mechanical clocks require regular maintenance to keep them running. So the frame needs to allow access to the gears.

So, I think I need to redesign the frame (again) to allow for nuts-and-bolts. Because I think each time I open up the frame it gets compromised and is more likely to fall out of alignment.

While doing some tests with a bolt and nut, I found a very simple way to attach it to my existing frame. So I added it to my current clock.

I want to extend the frame and add a few more bolt points, but for now this might help the existing frame.

It doesn’t even interfere with any existing features on the clock. And is even hidden behind the clock face. You really have to search for it from below to even see it.

I don’t like any of my options to fortify the frame. I think it is just going to look awful…

But I do love it when the clock is running… so I will try to see what I can do…

Just adding this disclaimer; I do not like how it looks…