Are you going to add jewels in your new design for the pivot points? In keeping with the “all on a Glowforge theme” I’m thinking delrin might be a good alternative to carborundum.

I don’t think I understand your question… would the jewels be for aesthetics or function?

If you are referring to the points of the frame where there are moving parts to prevent wear-and-tear, that makes sense and I had not considered something like that yet.

If you mean just add some “bling” then, no.

A bit of acrylic with a drilled hole halfway through and bamboo skewers with the point centered in the Acrylic would have the resistance down like a jeweled watch, and likely not needing the hardness of an actual jewel or steel as would be found in a watch.

My rods are brass, the bamboo ones were not consistent enough for my needs.

Would the brass cut into the acrylic? (I would want to make sure to polish the ends of the brass rods.) I would love to cut the frame out of clear acrylic if it would be strong enough (maybe 1/4" instead of 1/8" thickness?)

I am actually really liking the ideas here…

1/8 angles are stronger than 1/4 solids. like the triangles, 90 degree “bends” add strength.

Jewels in watches are used to reduce wear and friction. They’re usually ruby or sapphire (synthetic). Carborundum. They’re second in hardness to diamonds.

You’ll find them on every pivot point. Some are drilled with a dish & cap to allow for a micro drop of oil to further reduce friction & wear. They are also sometimes used in offset pairs so the gear axle makes contact with one or the other depending on the orientation of the watch so it stays consistent. You wouldn’t need to do that.

I’d start with the pallet axle and as you gain time with the clock keep going after the next most frictional part.

I don’t think acrylic, especially with brass rods, will bear up that’s why I recommended looking at delrin. It’s hard but slick. Similar to the carborundum jewels.

I will definitely look into that if I can keep the clock running. That might even be what I need to keep the clock running…

But right now I think my issue is still mainly my frame. If it moves even slightly, the whole clock reacts.

I do like the idea of Delrin inserts for the axles… I haven’t witnessed any wear yet, but when I do, that is likely the direction I will head.

Some of my tests for the frame-braces are working out better than expected. I think I will completely replace the old braces with the new designs.

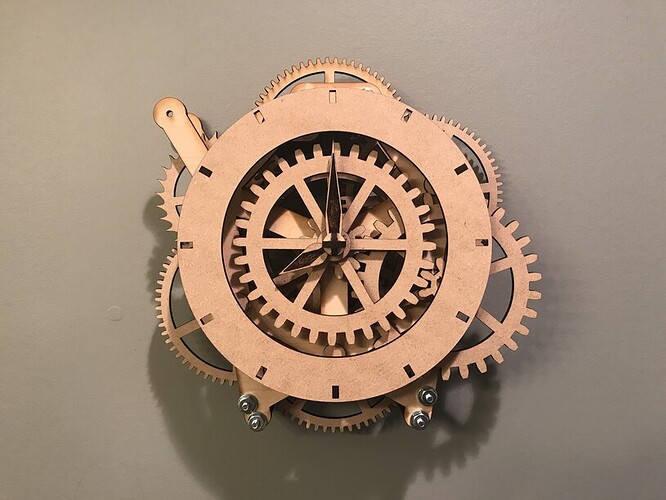

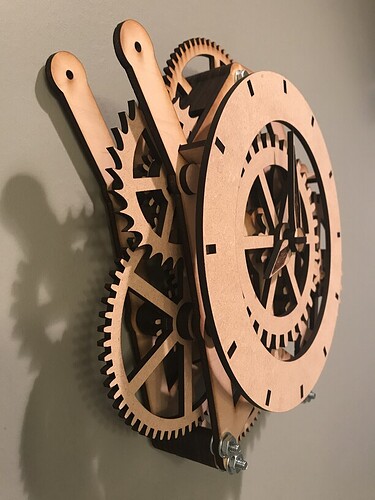

Here is a picture of the old style with the addition of hardware.

I don’t really feel like this method had any benefit, other than it can be tightened.

Here is a picture of the new style.

I feel like this method is much more pleasant to look at and should have a stronger hold (but, I am still testing this…)

(Note: This new frame is made from plywood instead of draftboard also.)

I have been trying to cut a new set of gears for the second clock, but my draftboard appears to have started to expand already. It hasn’t expanded enough for me to measure the change with my calipers, but it is enough to see that my tension-fit settings are not going to work… The holes are just too small now. I can see how this could be very frustrating for someone. It is for me.

I need to find a better way to do this… (I have already snapped and recut pins twice…)

Maybe I can sand down the pins? Either that, or recut all the gears with larger holes…

Edit: Wow, yes, sanding helped solve the problem! I will have to add that as a note in the instructions…

I had the same problem halfway through my clock, so I switched to acrylic.

I have also considered that… And now that I am changing my frame configuration, it might be easier now.

The only problem I have with the acrylic is that it seems less consistent in its width, but of course I am having the same issue with the draftboard now.

My plywood is slightly thicker (0.13) than the draftboard (0.12), but the acrylic is much thinner (0.10).

I have determined that I need better calipers. Two decimal places is just not enough accuracy for what I am needing…

My long experience with MDF is that it expands like a reallly long explosion into the puff of sawdust from which it came. It might take a few years but relentless.

The new frame design appears to be working so far. I am still adjusting the depth (or space between the frames), but I have high hopes as I am assembling the gears and installing the bearings.

I still need to cut down the new brass rods, and cut a new pendulum, but it is coming together nicely.

My initial tests with the new frame indicate that I have reduced/remediated the gear binding due to the minute gear getting too close to the hour gear. The smaller bearings are working well and holding the axles firmly.

Before there was a little bit of wiggle room for the axles to shift, because I didn’t want added friction from a tight hold. That allowed the gears to get to close and bind in rare occasions when they would both move towards one another.

I have the rods for the gears cut down. The gears are installed in the new frame, and everything is connecting.

The gears have not been lubricated or broken-in, so it is still rough and there is no way it would run yet.

I have both clocks on the same wall to be able to compare them.

I am considering changing the clock face too. Possibly add some numbers and make it larger to cover the bolts in the frame.

But then it might hide the gears. The gears showing is a cool look. You might want to skeletonize the face to show underlying parts if you make it larger.

I really like this idea!

You are right, I do want the focus on the gears, that was whole point to this design…

Instead of changing the face, I have been playing with frame and the new spacers.

The top spacer was the first test, and can be seen in the first photos of the new clock.

It worked out well enough that I am starting play with other areas.

Putting teeth in the frame? Cool! So many things to do to decorate the frame! Thinking crocodile with clock teeth…

That would make it a clockodile?

still rooting 4 u

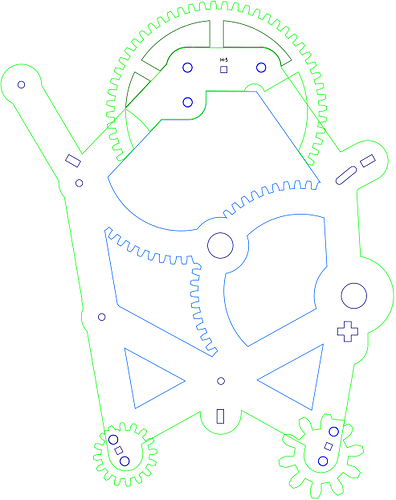

Possible new clock face… (and the old one for comparison)

I like the clean look and feel of the original. But, I think I would like the detail and theme of the new one.

What do you think?