I got a cheap one but it is pretty worthless, It might not cut your finger as it would take more power than it has, but that is the most positive thing.

I just took a flyer on this…

It could be junk also but we will see.

An “early bird” deal on an expiring “warehouse lease”? “Only 50 SETS” so it must have been a really small warehouse… This just has “scam” written all over it.

I tend to only buy brands I know. To many times I tried to “get a deal” and just ended up with trash. It is not worth the headache to me.

On a related point, a very high-end micro-sized table saw is the one from Jim Byrnes. I don’t own one, although I have seen one in person and it was pretty ridiculously nice.

…if, y’know, you ever want to go completely crazy with small table saws.

Thanks Martin, I took a look at it, will keep it in mind. For now my son bought me the one advertised on FB for Christmas, it got here about a week ago. Thing is so small it came in a box about the size of a shoe box and fit inside the mailbox. Not sure how well it will do but for now I’m covered on that.

Yes, but I paid through Paypal and they claim to pay only on delivery, And $20 is through USAA that burned PayPal for $2k when another did not deliver once before. So it is a nice test 4 different ways for well under $50.

And who knows “maybe the horse will really fly.”

I learned to not buy black and decker tools a long time ago.

These days whole industries are nothing but scams, “Were it not for scams and fraud, we would have no economy at all” when I said I was taking a flyer, it is just that, risky but worth it if it works out, and a worthy test of the advertiser, PayPal, and USAA, for less risk than when it was $2k.

I’m sure you will get at least 25$ of enjoyment out of the experience. And as long as you have some sort of separation with protection between you and whatever is on the other end there you might as well have some fun. If it shows up it will be really great till the driver part fails or some piece of plastic with an engineered expiry date cracks and it will start its journey to the landfill with the rest of the black and decker tools hehe. Confused, what was $2k? sry bit sleepy over here.

Long time ago I bought a new computer on E-Bay from a guy that was just posting stuff and did not have anything. Both E-bay and PayPal knew he was a fraud a couple of weeks before the purchase, but sent him my money before he had to deliver anyway. PayPal claimed to refund for proven fraud but offered me $400 as settlement, So I went to USAA who I am sure sends them many times $2k every day just deducted it from what they sent, and PayPal was madder than a wet cat,

My gear and axle design was working with the draftboard, but there was to much friction. The same design is not working great for acrylic. Either there is to much variance in the width or it is just seems less stable…

I think I can account for these variances by increasing the width of my pinions. I have high hopes for an acrylic geared clock; I just have to find the right balance.

I very rarely had a gear slip with the draftboard, but it appears to be a common occurrence with the acrylic gears. I need to use thicker material or more layers for the acrylic version, I think.

I think that the friction you complained about was helping you keep the gears aligned. Now with the Acrylic that friction is not there, and the fact that a cut is not perpendicular means there is pressure to the side that there is little friction to resist.

If you glued two identical gears top to top there would be a “v” groove forcing things to the middle, You could put them “V” to "A’ they would be forcing them to stay in place ![]()

That makes sense. I am going to see if I can double/triple the pinion first (they are much smaller).

I think my biggest problem is that I used several different types of acrylic. Each was a different width and it is causing me a lot of issues.

Acrylic is two or three times more expensive than draftboard too, so I am less likely to just try something. I put a lot more thought and calculations into work if it is with a more expensive material… that can be good, but it probably slows me down quite a bit too.

I proposed the tablesaw to my wife and she said “Yes” way to fast…

I ordered it and should be here on Tuesday, but now I am little scared of what she might have planned…

She did say I would have to clean out the garage so I would have room to use it. Maybe that is her angle here?

Now I can run down to Home Depot and grab some acrylic so it is ready to be cut down to try it out when it gets here!

I would not use draftboard for anything much but making clock gears of it is probably the worst idea. I suspect that if you looked at any gear suffering the most use would have a lot of “wear” in the form of individual crumbs displaced that would eventually wipe out the gears completely.

It might work long enough as it did for proof of concept but even Baltic Birch would hold up better. A couple of disks of 1/16 on each side of a gear would make sure the gear would not slide away,

So far the only damage I have seen to the draftboard gears have been dropping them.

One of my latest pinions broke a tooth, but I think I know when that happened too. At one point the weight slipped out of my hands when I was attempting to wind the clock and the drive-gear slammed into the pinion. I thought nothing of it until I saw a tooth missing.

Another time I thought the draftboard had expanded, but later I realized it was just a different batch of draftboard. I went back and measured some of my original pieces and they were fine. The new batch of proofgrade was just thicker.

My original clock is still running (periodically) and has been for months. Those gears are covered in Dry Moly and any wear would be shown by the lubricant rubbing off. But, I haven’t seen anything like that either.

I agree acrylic should be a better material due to the reduced friction. But other than that, I have not witnessed the other concerns mentioned.

It took several years for my desk to get ridiculous and it was 3/4 inch MDF, With the wheelchairs adding extra wear all the MDF in all the flooring here is also falling apart.

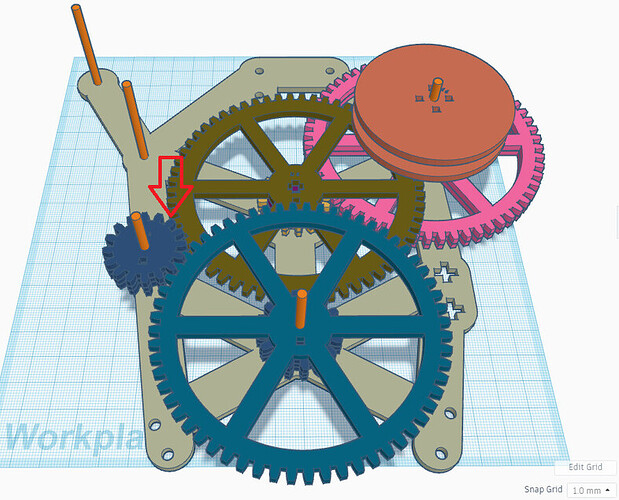

Well, I was playing around in Tinkercad again last night, testing out a gear layout, and I found an issue that will likely mean I have to redo the frame. AGAIN. ![]()

By making the wheels and/or pinions wider, it appears that will increase the likelihood of them binding with others. So it looks like I need to spread them out a little more.

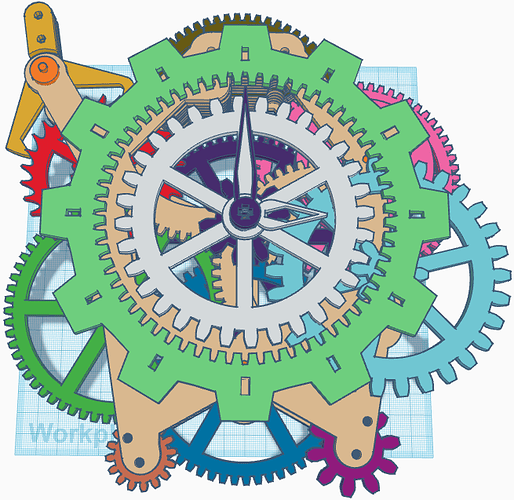

I think I have fixed the issue with the gears being to close, but now I want to make it look nicer…

Here is a new tinkerCAD link if you want to view it in a virtual 3D space:

(Note: the pendulum and weight are not displayed in the tinkerCAD.)

Purely an aesthetics thing but have you considered clipping the corners of the outside teeth on the face so their profile is more like you’ve got on the gray gear? Might enhance its look like a gear wheel.