If you are asking if I have enough scrap to cut a new wheel for the hour gear, I tried to (above) and none of the pieces were big enough. That was why I was trying to save this one.

So annoying when that happens ![]()

The drum axle was separating again, so I removed it to attempt to use the acetone to bond the acrylic again. While it was drying, my wife caught the cord with her foot as she was walking by sent it flying.

The drum fell apart, but thankfully the ratchet stayed intact. The gear was bonded well enough that it didn’t come off, but it cracked three of the six spindles on the gear.

Since the drum was in pieces I took this time to bond it together also, and reassembled the axle. It seems much sturdier now, but I don’t know if should be concerned about the cracked gear or not. I guess we will see if it implodes under the pressure of the drive weight.

I liked the update, but not the reason you had to post it!

Well the clock stopped again this morning. It is probably time to give it a good cleaning again.

It is seeming that it wants attention about every three weeks.

A far cry from when you started eh? I’d call it a success. ![]()

I was trying to examine the clock, to see where the hang up was that was stopping it, and it fell off the wall…

It snapped the pendulum into five pieces, but the clock frame stayed intact.

I put the clock back on the wall and let it run without the pendulum just to make sure everything else was still fine. It was running fine, but I could see that it wasn’t properly balanced. Other than that, everything seemed fine, until I went to wind it again.

It appear that the ratchet lost one of its teeth. Normally this should not be a major problem because it has so many other teeth. The problem is that the loose tooth is rolling around in the enclosure and getting in the way of the pawls operating.

I might be able to salvage it, but I just might need to start work on a new one. If I do, I would rather make a mantel/desk clock, so it doesn’t have to hang on the wall (to many disasters.)

Sounds to me like you are an evolutionary force; the clock design will adapt or perish.

I finally got up the courage to take the ratchet apart and clean out the debris of the three teeth that broke.

I meant to take pictures, but it was so hectic trying to get all the pieces to stay in place so I could put it back together I forgot.

If I cut I new pendulum it will be complete again, but I am thinking about designing one that is not screwed onto the clock.

(On top of all that, I have already started designing a new version that is meant to sit on a desk or mantle, but it will probably take as long as this one did. I will start a new thread if I post any information about that one.)

I found the clock design on Stephen Ressler’s web site. Downloaded it into Inkscape. Thanks for the referral.

It was fun to play with. I have learned a lot since then. I have had lots of issues with hanging the clock on the wall, so I am trying to design a desk/mantle version.

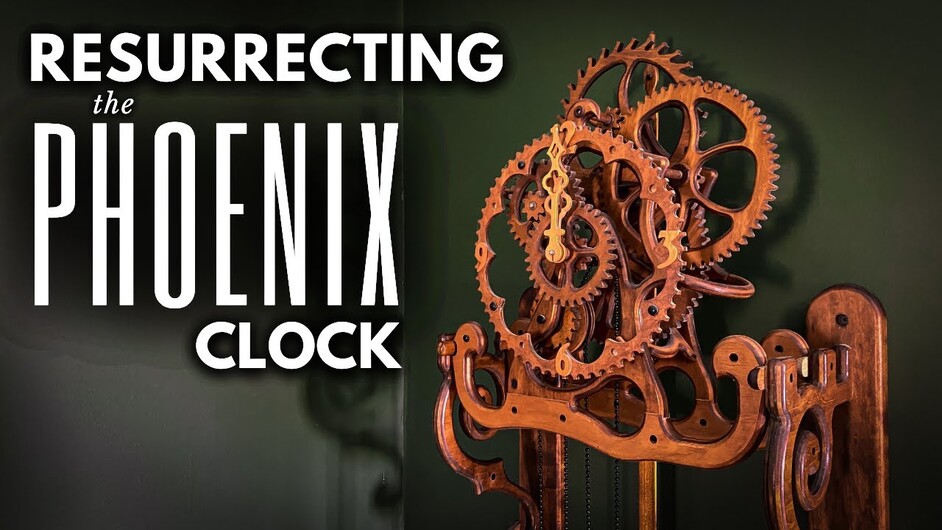

This topic always floats around as something to come back to. Here is a great video in a wooden clock restoration. A Kassner phoenix clock.

This guys channel is very polished. He inherited the dream machinist shop and is putting it to good use.

I have been looking at clock springs and REALLY want to make a desk version of this Glowforge Clock. I hope to have more time this summer, but we are going to be really busy with the kids again…

Still, I have seen some other clock kits that use a spring, so I am hopeful that I can get this to work if I can find the right spring.

(Leaving notes for myself here.)

This is a spring I am looking-at/researching:

https://www.aliexpress.us/item/2255800504702293.html

It is a 8mm width and 5m long with 0.25mm thickness. I think I just need to get a spring and play with it, but I should probably keep researching…