If the weight is wound on a larger diameter tool the extra torque should increase considerably. The fall of the weight per turn would also increase but the resistance would not increase greatly, So the power per resistance should increase.

The last pendulum test went well (eventually). I learned that I had the escape wheel on backwards…

It was working really well until my minute axle (still a cross-axle so I don’t have to glue gears) got caught on something. All the brass axles seem to work flawlessly, but I still have two axles that are the old design (minute and hour gear down). I am afraid I need to redesign them to get them to work, or at least redesign their pivot points…

I am trying to turn the gear chain very slowly to test it, since the clock will be running much slower in actual use. (I had been turning it at higher and higher speeds as I have been reducing friction on the gear-chain.) It will go slow for bit, then catch and stop, until enough torque is built up to break free. But that is not how the clock will run, if it gets caught, it will just stop.

I will try some wax first, but I don’t think that is a feasible answer; I don’t want to be constantly adding wax so my clock will run…

LPS 3 contains a wax that protects for years and might work permanently.

Thanks, that sounds perfect! I will have to look into that.

I hope to have a new video of the clock soon. I have just been SO busy last week.

Edit:

Is this the stuff you are talking about?

Yes but you don’t want it in the cans unless you expect tp use it up in a month. I n ever finished a can before it locked up.

I found some in the plastic container with a spritz thing like spray cleaner and that lasts very well.

You mean more like this?

That is it!

One review says that it “stays tacky”. Wouldn’t that have the opposite effect of what I am looking for?

Or does it really leave a “waxy” residue? That is what I am looking for.

Here is a short video taken during my last pendulum test:

It went much better, but something is still off. The pendulum will eventually stop swinging. I don’t think it is getting enough of a “push” through the escapement. But I might have something else wrong too, I am not sure…

I currently have beeswax applied to the non-brass axles, but they might still be catching, that would definitely cause the clock to stop.

What they are talking about is the beeswax ish material that gets left behind, but that is also what protects and reduces friction. In the case of steel with really close distances, the humidity overnight can lock up such pliers, and every morning I would use the crc spray to ease them. I used the Lps3 and have not had that problem again since 1975.

Originally focused on the Marine saltwater use they had a dramatic part of a boat show side show that they would take a raw 110 v socket and light, spray them down and then shove them in a deep bath salt water and screw the bulb in. When the light came on and they did not jump about from electric shock folk were impressed.

My pendulum still has a couple issues…

First, I think I need to wax the escapement, to ensure it doesn’t get caught on the wheel.

Second, I think my cross-axle is twisting (just ever so slightly) so I am losing part of the energy transfer from the wheel pushing it. If the pendulum were closer to the escapement it would have much less room for twisting, so I might try to reorder the gears to get the escapement closer to the front of the clock.

That might actually help with another problem I have seen where the weight cord is dragging on the bottom gear… So, reversing the orientation of the gears in the frame might solve both problems! That would put the bottom gear closer to the back and the weight cord in front of it.

Hopefully that will not introduce the same problem with my hour-hand gear then. That would put a lot more axle length between it and the power-drive…

Try making the escapement from thinner material (maybe acrylic to keep lateral stiffness). Also make the teeth pointier so you minimize the friction. You want the minimum resistance that holds but releases/advances easily with the movement of the pendulum.

I don’t think I have any thinner acrylic… 1/8" is the thinnest I have…

And I think my axle twisting was a bigger issue than friction from the escapement, but I do plan to play with acrylic also.

I have reversed the placement of gears in the frame to bring the escape-wheel to the front (closer to the pendulum), but this has added some complexity with the assembly of the minute axle. So I am redesigning it to make it a little easier to assemble. (It is near impossible right now…)

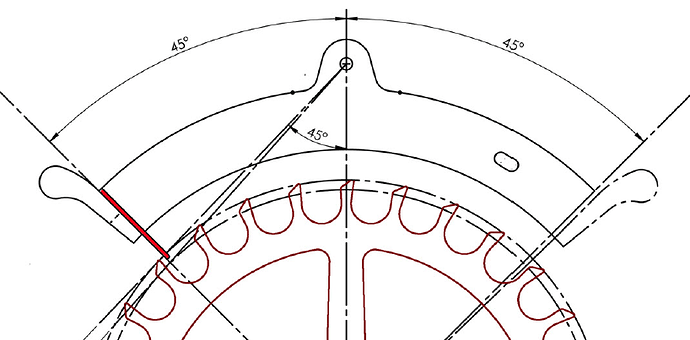

My current escapement is a variation of the “Deadbeat Escapement”. I might look at trying the “Graham Escapement” but I am not sure it would be the best choice for the materials… it looks really fragile and would definitely need to be done in acrylic (my best guess).

I will probably try the “Deadbeat Escapement” in acrylic first before I try the “Graham”.

I am also adding more weight, hoping it will translate to more torque without changing gear ratios.

yep. In clocks and watches you’d be amazed at how fragile these are. No ham-fisted handling allowed ![]()

I just realized that what I was referring to as the “Graham” was really “Brian Law’s” escapement based on the “Graham” where he moved the impulse-face to the wheel instead of the escapement…

It still seems very interesting and worth a try. My only concern is how narrow his escapement is where it engages the wheel.

But, I feel like I am really close. I just need enough power transferred to the pendulum to keep it swinging…

I will try getting the pendulum on a brass-axle too (currently still a cross-axle). But I will have to redesign the frame to hold it and allow it to transfer the swing motion…

You need to have the pallet & escape wheel set for minimum contact. If you look closely at the friction points during a “tick” you’ll see that the pallet is shaped so that the escape wheel’s teeth barely touch it as the pallet flips. The curvature of the pallet end is key - it’s often taken off a reflection of the curve of the wheel or hub. The escape wheel teeth are very thin and pointy to further that action. In most cases that’s where the critical lubrication is found as it influences the impulse timing of the clock (or watch). Wood is hard to get good long-lasting lubrication. That’s why I think acrylic might be a good alternative - and perhaps even a bit of graphite powder or even a teflon surface. What was that super-slick tape that someone found here a year or so ago?

Or, Bloxham’s gravity escapement is what’s used in really large clocks even today. That’s one that would seem to lend itself to a wooden clock as you can easily setup the falling weight to provide a lot of extra power.

If I were doing it, I’d actually use Harrison’s grasshopper escapement. It’s not as accurate as a deadbeat but it’s got a really unique style and elegance of line. If you really work at it you can get a pretty accurate clock (fractional seconds per month). But it’s likely no one who sees your clock will have ever seen a grasshopper. Bragging rights ![]()

Definitely try the acrylic for the pallet. They’re usually harder than the gear material for a good reason. You could even keep the wooden pallet fork but use an acrylic insert for the tips or friction surfaces. That way you could have the rigidity of the 1/8" wood but the hardness of the acrylic and not lose the overall “woodness” of the clock as just the two inserts would be acrylic.

That could be cool too. instead of boring curves have them be pierced grasshoppers, I bet nobody has seen that!

There is always 1/16" Wenge? If you can find it in Lignum Vitae that has natural oils and is extremely hard ![]()

I did look at the grasshopper escapement, but I didn’t want to try it for my first clock. I wanted to try the deadbeat first (only because it appeared more simplistic and I assumed it would be easier.)

What you described sounds like the version of escapement Brian Law used, were he moved the impulse-face to the wheel.

Is that what you are referring to?

I really like this escapement method. I wish I had seen it before I designed this clock, because I might have tried it instead. But the deadbeat does still look more simplistic, so I probably still would have tried that one first anyways…

My current design will not work with it though… The pendulum needs to swing past the wheel on a free axle. My wheel axle is fixed on both ends.