My husband casts metal, and we want to know what we could use in the GF to create an engraved mold for doing so. He has used wax, sand and plaster of Paris for molds in the past. It would be fine engraving- he’s interested in making custom medals for his fencing club.

I would probably use acrylic to make a positive and then do a PoP negative. This would give you a nice crisp material for the positive that the plaster should work well with. The only possible issue would be the rough edges of the engraved area holding the plaster.

I haven’t done this before, just how I would start.

I’d do a defocused engrave to lessen that issue and then follow it up with an acetone flood to smooth it all out. Some precision of detail is potentially lost that way but short of SLA printing at .005mm I don’t see many options that would get you smoother.

If he does sand casting then making a model in wood to sand cast from, would be fast and easy it might take a bit to make sure sharp edges and vertical sides do not grab the sand too badly but if you are making jewelry you will have the needed tools. Talcum powder does stick better to wood,

On the other hand acrylic shoud burn out cleanly if you do not try to burn out too fast.

I haven’t done it either, but engraving a positive into acrylic or silicone to then mold into plaster or greensand would be my first thought.

Problems and Support is for opening trouble tickets with Glowforge support. I’ve moved this to the appropriate forum, but they will still check in as the ticket has already been opened.

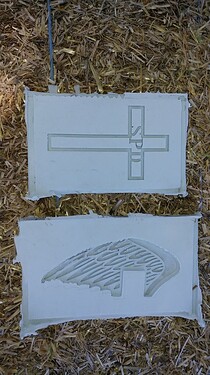

Not sure if this is what your looking for or not, but I’d bet it’s close.

acrylic mold box

This might be step 1 or 2 of many.

This might be step 1 or 2 of many.

You might be able to engrave wax stock to make the model then go direct to lost wax.

You could also make the model in acrylic, then make silicone molds from that, and there are silicones that will withstand low temp metals like pewter so you can cast direct.

Or engrave silicone directly. You could make a mold for casting depending on the metal needed, or make the model for casting or stamping in plaster.

For low temp metal I make the design out of wood or acrylic and then make the silicone mold out of that.

Not polished yet

Thanks for all of the great feedback! I’m not sure what we’ll do yet but one of these ought to work. If I could get the GF to work- but that’s a different problem! Really beautiful examples!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.