I was fascinated by the images from here, https://archinect.com/tanat/project/primordial:!

They can all be produced from flat material, but I don’t want to make parts and cast them in silicone, because that’s expensive, slow, and messy. So how about cutting them out of EVA foam? Even better, what about cutting them as negatives out of EVA foam and casting plaster in the forms?

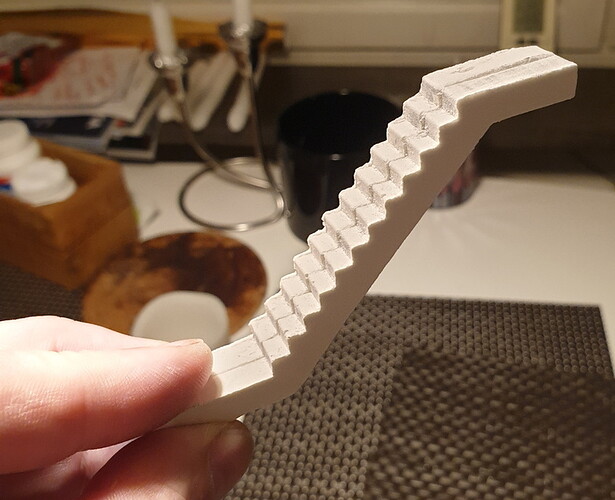

Maybe this is an ancient idea, but I’m going where inspiration takes me, so, here’s my “positive” test.

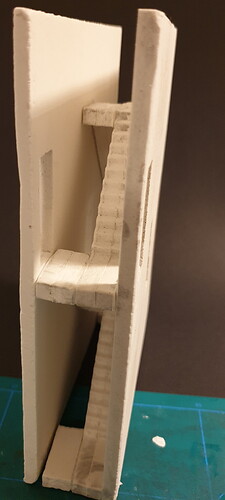

And here’s me cutting a “negative” out EVA foam - and gluing it to a EVA backing plate;

I cast plaster in these (dental plaster or ultracal, not the weak stuff that goes thud, but the hard stuff that goes PING);

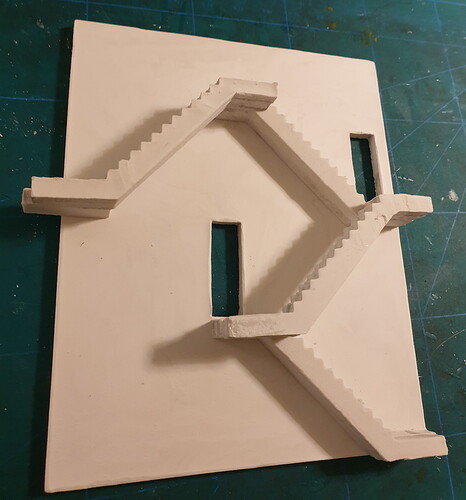

Then I mounted them on a plate - that I formed the same way, to make a staircase that I can place in a bookshelf.

Upside to this method; EVA foam is very cheap. Plaster is very cheap. The turn-around for a project like this is a few hours. The staircase parts are two EVA foam mats (6mm) thick.

I particularly like that I can iterate on this so quickly.

Downside; it kinda looks crappy, what I’ve come up with so far.

Except… my sons name sign, still in progress, is looking kinda cool. The sparkles are actual sparkles - copper oxide crystals formed on the surface of the plaster where we added pulvered copper, hydrogen peroxide, white vinegar and table salt.

Anyway, hope this gives someone some cool ideas, if you make anything similar, let me know!