Well I have to confess that I lied to the GF  and told Koptis that it was thick PG

and told Koptis that it was thick PG  Clear Acrylic, but cleaning all 3 lenses (one the left side of the gantry, one to the left side of the printer head and the bottom facing lens) has made some beautifully smooth cuts on plastic covered extruded acrylic.

Clear Acrylic, but cleaning all 3 lenses (one the left side of the gantry, one to the left side of the printer head and the bottom facing lens) has made some beautifully smooth cuts on plastic covered extruded acrylic.

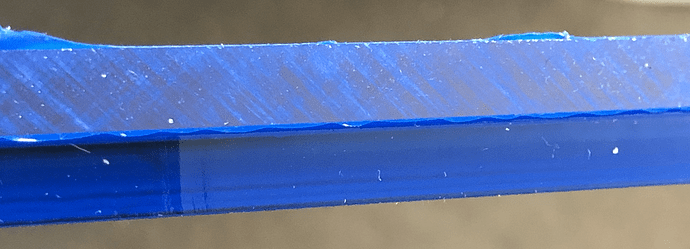

1st pic is the long view of laser cut versus saw blade cut:

2nd pic is close up comparison of saw versus laser:

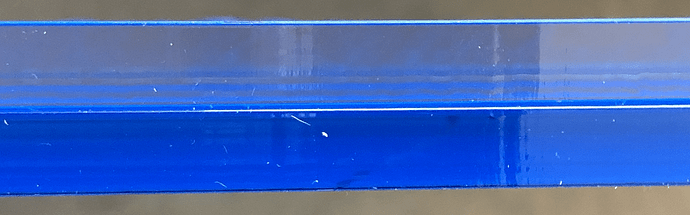

The last 3 are the mated laser cuts side by side:

So lens Cleanliness is next to Laser Goodliness (and even your GF  will forgive for lying to it about non-PG)!

will forgive for lying to it about non-PG)!

25 Likes

I’ve been throwing around the idea of making a custom aquarium with a built in filtration system. Any idea if there kerf would cause a problem?

Not sure if you had meant to reply to the thread addressing the kerf discussion, but I have seen non-GF  postings taking about aquariums/terrariums being made on a laser.

postings taking about aquariums/terrariums being made on a laser.

About the only thing that I walked away with (from those forums) was how do you keep them clean and does water leech out this from the acrylic?

1 Like

Just wondering if you could see a noticeable tapering effect. I’m reluctant to start the project if it’s doomed to begin with. I’ll have to google aquariums/terrariums.

I would start by making a scale model, something tiny, see if there are any defects in the joins, and test its waterproofness.

You shouldn’t let the fear of failure stop you from trying something

Very good point. Definitely going to try a small scale one

![]() and told Koptis that it was thick PG

and told Koptis that it was thick PG ![]() Clear Acrylic, but cleaning all 3 lenses (one the left side of the gantry, one to the left side of the printer head and the bottom facing lens) has made some beautifully smooth cuts on plastic covered extruded acrylic.

Clear Acrylic, but cleaning all 3 lenses (one the left side of the gantry, one to the left side of the printer head and the bottom facing lens) has made some beautifully smooth cuts on plastic covered extruded acrylic.![]() will forgive for lying to it about non-PG)!

will forgive for lying to it about non-PG)! ![]()

![]()

I lie to Arges all the time. “Hmm… This piece of wood is about as dense as

I lie to Arges all the time. “Hmm… This piece of wood is about as dense as

postings taking about aquariums/terrariums being made on a laser.

postings taking about aquariums/terrariums being made on a laser.