I learned something today that is probably pretty obvious, but I thought it might help somebody else some time.

I sent the following email:

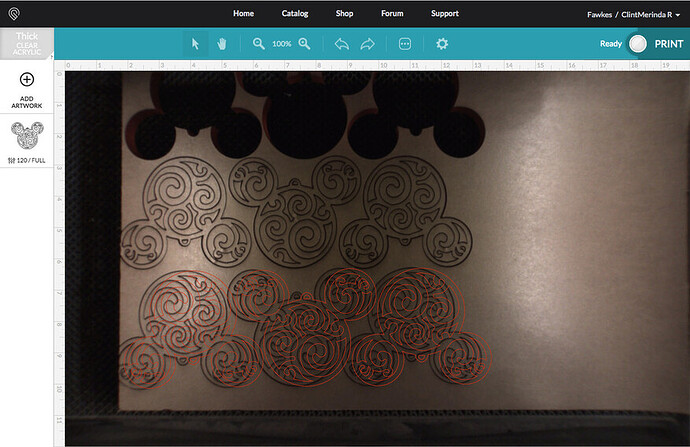

My alignment has been dandy, and then suddenly this afternoon, I am cutting off the left side of my prints.

Measuring my acrylics with calipers, entering the thickness.

Doing everything that has always worked perfectly, and now I have a bunch of miscuts.Attached is an example of the sort of trouble.

I did check my lid, no debris. It’s equally as flat when closed as it has been since I got this unit.

Advise me, o great customer delight engineers.

Since I wasn’t cutting, and since the machine was pretty filthy, my husband advised that I go clean it, not just the lid camera. He’s the tidy one in our relationship.

It was time anyway, so I did.

Here’s the next email:

Hey team,

Further to the former, I shut everything down, cleaned everything as per the manual, and restarted it all.

Cleanliness is next to troubleshooting, I guess.

My Glowforge is aligned well once again.Thanks for all you do to keep the masses happy.

So there you have the lesson.

Keep it clean, or follow the cleaning instructions every once in a while.