Yeah, so far, I’ve been pretty pleased with the result. I might need to make a jig, but I would be remaking the jig all of the time like in your example because no two of the boards are exactly the same size or thickness. I just kind of go with what the wood wants…and if it is slightly longer by the time I get it glued up and planed/sanded, I leave it as long as it can be, but still fit in the Glowforge.

The engraving is only about 2.5" tall and maybe 4" wide…maybe 5".

That makes sense to do this, and I might with more of them that I do in the future. So far, using sight and some of those alignment methods has worked pretty well. This is just text, so it is not as noticeable if it is off by a very slight amount. If I started using some shapes for scoring that came close to edges, and your eye could tell easily that it was off, I would definitely have to adopt a different method. Like @evansd2 did with his slate piece…it had that square all of the way around the piece. That would have noticeable if it was off even just a little.

I still think eyeballing this would be about as difficult as just using the camera to place it. Am I missing something? With it sitting on top of the chipboard score and not registering against it in a corner, how would it be exact?

How? I guess I didn’t think there was that much room to allow for that?

Everything in the design will print relative to where it is in the design and to other elements.

You don’t need it registered to a corner. Just to the score marks.

Draw a rectangle the size of your cutting board. This is the object outline. If you need to, because of size being outside of the cutting area just draw 3 lines.

I would draw both the rectangle and the scoring lines if it’s too big.

Put the score lines directly on top of the rectangle.

Align your design to the rectangle.

Hide the rectangle and save it with your design and the score lines visible.

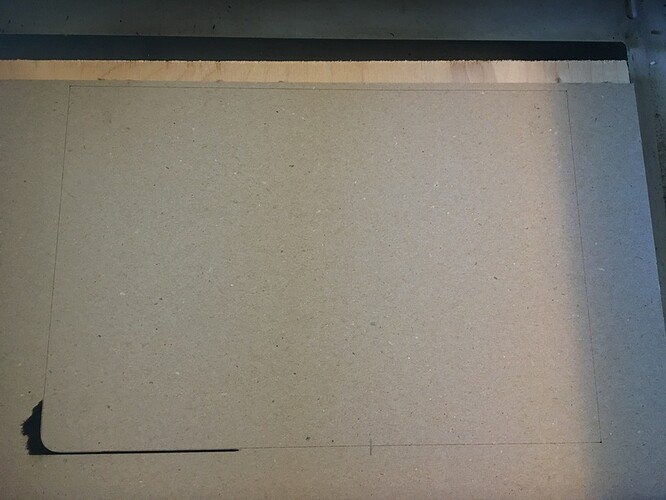

Score an outline on the chipboard.

Place your cutting board on the scored lines with the front or the back aligned (however you set up the design)

Ignore the score and run the engrave.

1 Like

Makes sense now.

Each board is different size for me, so I would be making a lot of jigs like this. Or, I guess I could cut them all the same size. I am milling these from rough maple though, and there is often a character piece or something I want to keep in the board, that ends up making the width or length slightly different.

The thing about not having a firm zero point in GF is that to use a jig to its full potential you pretty much have to cut it new every time you fire up the glowforge. If it recalibrates, your alignment is now potentially off.

It all comes down to your precision needs. If you don’t need that level of accuracy, then jigging is a waste of time.

2 Likes