I am looking for recommendations on what materials work best to make a coaster. I am interested in using a type of wood and acrylic like TroLase from Trotec Materials. Is there a material that is easily available that will not damage with getting wet? Or is there a cheap coating I can apply to a material to get the finish that is best for a coaster?

A good acrylic spray will manage almost anything and cork is a great coaster before you do anything to it.

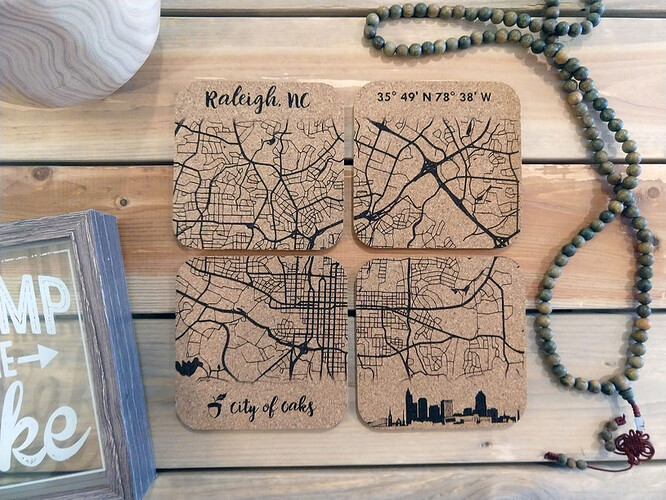

you can buy cork in thin sheets and glue it to most anything. then engrave or score the cork. you could also put in a sheet of thin cork engrave and cut it out to fit whatever you use for the bottom.

Slate coasters work great and last a very long time. Cork coasters work well but may degrade over time depending on use/abuse. Acrylic seems like a poor choice of material for the body of a coaster, but could be used effectively as a surround/spill guard on cork or maple. JPPlus and JDS both have lots of engravable coaster blanks available in various materials. I’ve had some decent success with the JDS laser-engravable leatherette coaster blanks, although they are much more sensitive than slate; leatherette needs precise settings, slate is way more forgiving (and poorly engraved or unsold slate coasters can be sandblasted blank and reused!)

Leatherette, tile, and slate coasters.

slate coaster blanks have these little foam/rubber feet pre-installed to protect table surfaces from getting scratched. If you use tiles, you would want to add some feet, or a layer of felt or something.

I just laser scored some slate coasters I was able to score from Michael’s. They look really good. Sprayed with shellac first and it really pops

I was thinking of potentially inlaying an acrylic or wood engraved piece into a cork base that has a rim to enclose the potential not as clean laser cur edge of the acrylic. I will look into some slate as these seem like a good coaster option.

Have you worked with wood coasters much/ at all? Do you have any advice with these?

I have not worked with wood coasters, although I do own a set of bamboo coasters that work wonderfully and would likely engrave well.

My aversion to acrylic for coasters is based on two lines of reasoning. First that wet acrylic is slippery and I wouldn’t my beer to slide around or for condensation to run off the edges onto the wooden surfaces which I am trying to protect. Second that acrylic is heat sensitive and I wouldn’t want a hot cuppa to warp it… probably less of a concern as my hot drinks aren’t really that hot, but still.

At 300 F as a softening temp I don’t think boiling water would get there. It can warp while engraving but the temps are way higher,

AFAIK 300°F is for reliable thermoforming. Based on what I have read from various plastic manufacturers and a few hobbyist forums, Thin extruded acrylic can warp/begin to soften around 80°C (176°F). This is apparently why it is a poor choice to use thin acrylic for the lid of a turtle/snake vivarium.

The slippery/drippery issue is really the main reason I personally would avoid acrylic for coasters, and also why I tend to prefer cork for the coasters that I actually use most often (vs slate coasters which I prefer aesthetically for display). The downside there is that the cork coasters are not particularly easy to clean, they get funky and gross over time.

Is not recommended for lasers for that reason, I have accidently had some and it is a mess to cut.

Not sure that I agree with that statement.

From Universal Lasers:

Cast acrylic is ideal for laser engraving because it creates a frosted surface. … Extruded acrylic is ideal for laser cutting because it forms a flame polished edge during the laser cutting process.

From Epilog Lasers:

There are actually two types of acrylics suitable for use with the laser: cast and extruded.

Cast acrylic sheets are made from a liquid acrylic that is poured into molds that can be set into various shapes and sizes. This is the type of acrylic used for most of the awards you see on the market. Cast acrylic is ideal for engraving because it turns a frosty white color when engraved. Cast acrylic can be cut with a laser, but it will not result in flame-polished edges. This acrylic material is better suited for engraving.

The other type of acrylic is known as extruded acrylic , which is a very popular cutting material. Extruded acrylic is formed through a higher-volume manufacturing technique, so it is typically less expensive than cast, and it reacts very differently with the laser beam. Extruded acrylic will cut cleanly and smoothly and will have a flame-polished edge when laser cut. But when it is engraved, instead of a frosted look you will have a clear engraving.

From Trotec Lasers:

Cast and extruded acrylic adapts very well to laser technology and both are an ideal material for laser processing. It is beneficial to have a good understanding of the differences when selecting the right acrylic for your application, because each type will behave differently to laser processing.

That was not my experience, but attempts to cut simply melted back together after the laser passed by.

Interesting. I wonder if your settings weren’t dialed in quite right for that particular acrylic, or maybe if you were using an acrylic with a specialty formulation?

I don’t know of a good way to visually identify different qualities and types of acrylic if they are not labeled, but it would not surprise me at all to see different batches of acrylic respond differently to the laser.

Shoot, even the Proofgrade cut settings for differently colored PG acrylics aren’t the same: 20 speed units of difference (for a Proofgrade Cut operation) between the white and the black medium PG acrylic!

I bought a sample pack of acrylic and it was all acrylic where most were Clearcast cast acrylic and a few had no label, All the Clearcast did well, and most of the unlabeled did not.

I don’t think this was a cutting issue (though that was my first thought) but going low so as to not cut through, or really high there was the same melt back

maybe there is a Goldilocks setting that’s just right…

…that thin line between smoking your clutch and burning your tires when the flag drops…

I should add that I am not an expert in acrylics, or plastics. Or lasers.

Thick cork coasters are my absolute favorite kind, both as a coaster user and a laser engraver.

As coasters, they’re lightweight, effective at protecting the furniture from condensation, look good, and cheap enough that I don’t care if they wear out eventually as any good coaster will TBH.

As a laser enthusiast, I love how easy they are to customize. Cork turns fully black with almost no power at all. I engraved these at 1000/7/225 – just 7 power! Any more and you actually create ash that can smudge.

They’re $15 for a 24 pack on Amazon.

If you are inserting precut coasters into the Glowforge, what have you found is the best way to make sure they are aligned and centered?

My camera alignment is spot-on, but if you wanted to be sure, it’d only take a few minutes to measure your coasters and make a jig for them.

Okay sounds good.

dan84: any chance you could share the link to them on amazon?