Hi everyone.

I finely got my Glowforge after more than 3 years patiently waiting, and have had a lot of fun the last 3 weeks.

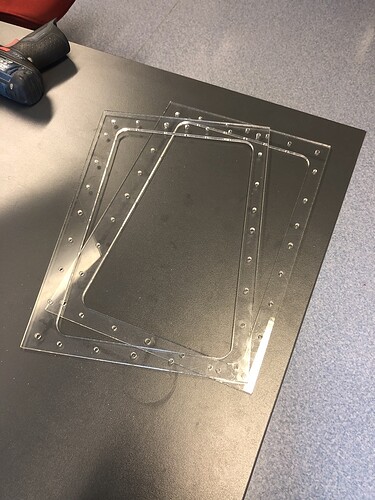

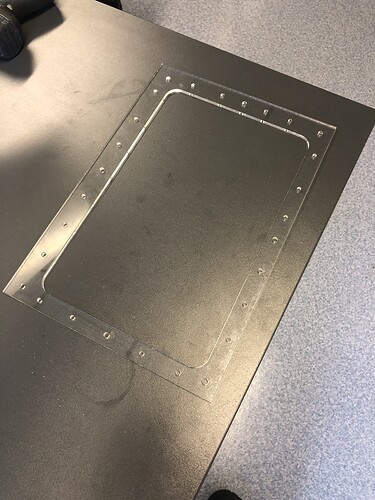

But I run into a challenge the last day. I made some frames in Acrylic for a machine at work, but it’s to crispy, and it brakes when I screw them together.

So my question is, are there some softer plastic that are safe to laser cut? And if there are, what’s the name of it?

There are several that are softer/less brittle and are still laser safe.

Delrin is expensive but great for industrial applications.

Johnson Plastics sells a modified acrylic that is not as brittle, but it only comes in one thickness.

Delrin would be the go-to there I would think or cork sheets for a more traditional seal

Is Delrin available as transparent? I didn’t think it was, but maybe so. Don’t know if that is a requirement of the OP.

One thing you can try is to anneal the acrylic to make it more resistant to breakage. That would involve putting the cut pieces into a 180 F degree oven for at least an hour or two. Do a forum search for “annealing acrylic“ for more info.

I did not see that transparent was a requirement. If so there would be few possibilities of any sort and a Waterjet cutter more useful than a laser.

I was thinking more gasket than structural frame, and thinking even leather might work in that case. As structural I would think plasma cut metals like stainless or aluminum would fit the need better.

It does´nt need to be transparent

I had no trouble with cracking when screwing pieces of acrylic together but, I tapped the holes to match the machine screws I was using.

This behavior means one of several things may be happening:

- Your material is a poor grade of acrylic, or isn’t acrylic at all. If this is Proofgrade, move to the next points.

- The surface you are screwing the parts to is not flat.

- You are overtightening the screws, by a lot.

I would look at addressing these points before looking at changing the material. I have done a lot of assembly with acrylic and it is usually plenty tough for this type of application.

In addition to all the points below, you can also try annealing the acrylic. Bake it in the oven at 180F for 1hr/mm for full annealing benefit or about 3 hours for “good enough”.

This question is outside our team’s scope. I’ve moved it to the Beyond the Manual so the discussion can continue there.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.