I have a friend who’s man cave is set up like a pub. I made this just to see if I could manage the artwork and offered them to him as a gift, he wouldn’t respond to me so I have them here to use for myself now but the challenge to myself was met.

pretty cool! where did you get the coasters and the box?

I cut them out of Padauk wood I got from my supplier. The box was cut from 1/4" stock, the outer ring on the coaster is cut from 1/8" stock and the bottom of the coasters are cut from 1/16" stock and of course the cork inserts were cut and glued in. If you look close at the top of the box, I cut 1/16 dowel holes in the corners and used dowel rods to line everything up then sanded them down to the surface.

Everything in this project, with the exception of the dowel rods was cut on the GF.

Side note, GF boast up to 1/4" material but once you get above 1/8" threshold you start having issues with it cutting through.

Great job!! Very professional looking!

That has not been true for me for coming on 3 years. Now, when my machine needs cleaning that’ll be true - or with plywoods with unknown glues that can be a problem - but 1/4" ![]() stuff, or hardwoods that are the same species as the PG stuff, or acrylic; 1/4" cuts like butter.

stuff, or hardwoods that are the same species as the PG stuff, or acrylic; 1/4" cuts like butter.

If you’re having problems, you should probably clean your machine ![]()

“Drinks on me.” Very clever.

Thanks for the suggestion, I’m slightly OC and try to keep my machine as clean as possible at all times. I have some Baltic Birch plywood that could be questionable and have taken that into consideration. As for the Padauk, I typically use the Cherry PG settings and it works fine on the stuff 1/8" and I’ve been playing with various settings on 1/4" but it never fails, when I have a 1/4" cut despite the cleanliness of the machine or the material I use, I still have issues with it not cutting all the way through. It does ok on acrylics at 1/4" but even the Padauk will not cut clean and has given me a lot of heart ache (and expense) trying to get it right. It is so bad, I’m personally resolving myself to 1/8" or less on thickness. I would try going all PG stock but I have had nothing but nightmares about getting material out of GF, I will give them this boast, my last filter was delivered within a week of the order. Even with that being said, it took 2 months to get some 1/4" Cherry plywood to my home, missed some Christmas gifts I was hoping to send out, so I have sourced supplies that are laser happy from other locations.

Thanks Christy, just seemed appropiate ![]()

I did this set for my brother and his wife, they live in Chattanooga but it seemed to be a running theme for a while so I never posted it.

Who would turn down such a cool gift? Guy must be nuts.

Ah yeah, there isn’t PG Padauk…yet!  's boast is well deserved, but there are always exceptions

's boast is well deserved, but there are always exceptions

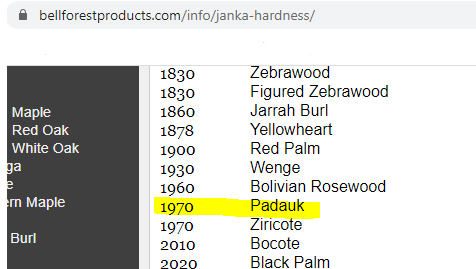

Possibly of use - I tend to find that knowing the Janka hardness of the wood gives me a better starting point for finding a setting that works - and then @evansd2’s material test to get a good final answer. Sometimes there isn’t a speed at which one pass works, but I’ve never found something that I couldn’t cut using that combo (there are obviously hundreds of things I haven’t tried!).

If you review my comments I think what I said was I use the Cherry PG settings, I’ve done multiple passes, tweaked the settings, there is very little I haven’t tried. I checked out the Janka Hardness link, Padauk is not rated in it. I am really happy to know you haven’t had any issue with cutting 1/4", truly I am.

Nice gifts! Your friend is missing out.