Im planning on using EVA foam, which is safe to cut. We have an abundance of it, and always stock up on it when it goes on sale as it has so many great uses.

That should work great

Me too man! In the Navy we were required to outfit our boxes with studs in the drawers to hold each wrench, socket and tool.

Inventory at a glance, because if a tool is missing, the aircraft you were working on is down until the tool is accounted for.

Custom foam profiles are much more attractive and professional looking.

Amen! That’s real pretty. I’ll probably be doing similar for Christmas ornaments that date back to my great grandma’s childhood. Currently packed away each year in shoe boxes with toilet paper. They are going to get a proper home, finally.

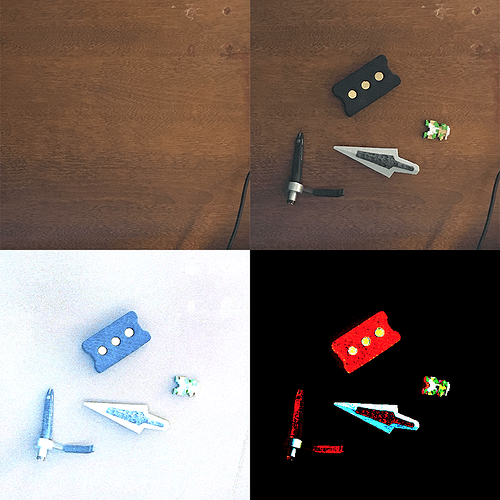

What Im hoping will be easy with the glowforge is object detection and smart outlining. If we can export a base image from the glowforge before object placement, then subtract from it after image placement, it leaves us with the difference data (would be better with more lighting to not deal with shadows). This could be used to determine shape and potentially be used for cut paths.

While it would be cool if the GF software did this, if the GF can export the image, and you have photoshop or most other image editors then you already can. I would rather see them concentrate on making the controls as good as they can, and leave image editing to the image editors, but that is just me.

This is very high on my project list!

This is on my list too

cant wait!!

This isnt something im expecting or hoping for on initial release. I can most definitely do this myself, but I do see it as a very useful implementation down the road if they are able to pull it off.

Dan has mentioned using the detail camera output paired with the overhead camera to produce a 3d ‘scan’ of items on the bed for other applications. So if you couple that with object outlining it could be provide users with some pretty useful tools, which is what the glowforge’s marketing call was about to begin with… taking the hardware that exists, and using modernized software capabilities to allow end users to do more, without having to write a multi-filter image comparison algorithm. I think this is right up their alley.

Like I said, not something im expecting immediately… but it would be a shame to waste the potential they have for things like this.

Thank you for your service!

This got added to my very long idea list in the first couple days after I decided to buy a GF.

Thank you, but I thank the Navy for the opportunity, the training and the adventure. I cannot imagine a better introduction to the world and other cultures for a young man.

Not just you. +1

And modest, as well. God Bless you, and all our Troops! What aircraft did you work on, if you don’t mind me asking? If I had good eyesight, or if lasik was around back then, I would have tried everything and anything possible to have become a fighter pilot.

Do you guys have some info im not privy to? To my knowledge we know very little about what the software is going to contain, or even what state its in.

From the last update dan gave, it seems that the hardware is the major hurdle here, as he didnt mention issues with the software at all. The ‘controls’ (im not sure what this refers to either) could be completely finished, and maybe theyre working on getting the hardware up to spec while the software team looks for features to add.

@jkopel Im curious: what are you defining as ‘controls’, and what features from the software are you looking for?

Don’t want to pollute the thread, but I rebuilt engines for everything in the airwing - circa 1974-75.

A6, EA6B, A7 Corsair, F4 Phantom and of course F14 Tomcat.

Those pilots… "aviators"once carrier qualified, launch and recover at night, in foul weather - whatever.

Never saw a machine take the punishment of a carrier bird, and the guys that fly them have steel nerves.

I could talk about this all day, but I will spare the forum members and shut up!

Thank you for the kind words.

I am mainly looking for the Glowforge software to be very good at dealing with the laser cutter part of the process, and to leave drawing and layout to other tools that are already well developed for that purpose. The idea of it being mainly a “printer driver” style plugin is attractive to me, although I have no problem with using a stand alone app that imports SVG/PDF/DXF/ whatever.

I see it needing to handle positioning and previewing cuts, and identifying color/layers for power/speed (and focus?). I assume it will also need to interact with the cloud as far as authentication and job storage/retrieval/queuing, but that might be a separate application? (no idea at this point). Other things that are unique to the laser like nesting and optimization of cuts might be useful as well.

By “controls” I mean the on screen or parametric tools used to position a file, scale and rotate it if needed, and preview the results before you push the big go button. There is plenty of challenge there already! Since they can improve and update whenever and for as long as necessary I really just want them to get the important stuff working and then SHIP!

I saw a video that showed a glimpse, and there was a “your projects” icon on the sidebar, so I assume that feature will be part of the final build for us.

The only other features shown there was a “user” number and the website to log into.

My perception is the software is close judging from what we have seen.

I have no idea how many issues the team is struggling with to get all aspects to culminate as close to simultaneous as possible into our wonderful machines, but there will be the last ones to fall into place - and then @dan can get us all off his back.

I’m quite sure that will be a high point for him, almost as much as it will be for us!