Here is my observations and settings:

Cutting 1/8" Nylon 66 Sheet on my GF Pro:

Speed: 140

Pwr: Max

Passes: 2

Engraving: Used the ProofGrade “Medium Black Acrylic” settings

I also applied a laser mask to both sides (reason below).

Why use Nylon: Greater durability than acrylic (I’m making a STEM hydraulic press for teaching Bernoulli’s principals)

Observations: Nylon cuts well, but it does have a tendency to liquefy rather than vaporize (like acrylic). This means the use of two passes provided better dimensional results than slowing way down and just melting everything in the Heat Affected Zone (HAZ). The cut edge does not have the clean and smooth finish of acrylic, but dimensional accuracy is very good (as previously mentioned). I found that a fair amount of liquid nylon gets on the surface of the sheet as it is being cut, for this reason I used a laser mask to make cleaning that up as easy as pealing a sticker. I also used the mask on the underside as this is where most of the liquid nylon settles. There is a slight surface finish difference between the top and the bottom with the top being much nicer and free of any signs of a HAZ (after laser mask removal). The bottom does show some local HAZ where flame-out burns the edge of the laser mask and slightly mars the surface finish.

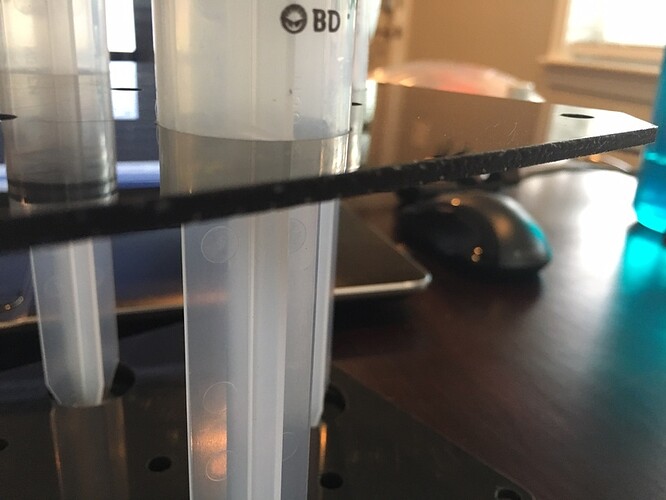

Here are some pictures of the Nylon edges (the last photo shows edges that i lightly sanded next to as cut):

23 Likes

Hey, Welcome to the forum!

Thanks for the demo, I’d like to try some nylon, got a link?

1 Like

I ordered my stuff from McMaster-Carr:

Link to Nylon 66

2 Likes

Thank you! The physical characteristics interest me. Acrylic is unforgiving in certain applications.

I am interested in using laser-cut acrylic or nylon for a food prep application, basically a strainer, but worry about cut byproducts ending up in the food. Is anyone aware of information on cut plastic intended for food contact? I am hopeful that there is a way to make this work but mechanical cutting may be necessary.

The FDA lists specifications for what they call the Cumulative Estimated Daily Intake (CEDI) for food contact substances (meaning if it is not in the database it is not authorized by the FDA for food contact). It will list the amounts of material allowable.

Link to FDA Site

1 Like

Is this safe to laser? I was told a long time ago that anything that has been put together with resin is a firm NO NO on the laser and to always run the airfilter when using the rotary cnc with anything resin due to the same hazard. I would love to laser carbon fiber, G10 and nylon 66 but worry about the damage to the machine as well as health of those around it.

Most stuff you cut on the laser produces effluent that you don’t want to inhale, as I am venting the process air outside, breathing it is not much of a problem (but everyone should decide for themselves what stuff they want to burn in their laser).

Universal Laser Systems tells us Nylon in laser safe (link below), that is good enough for me, but beware and “beyond the manual” warnings and all.

Link to Nylon on ULS website

1 Like