So I had this idea for a while and finally got to it: an extension spacer for the lens so that you could engrave/score (or cut) the inside of a tray up to about 1” deep.

Normally you are limited to trays no more than 0.5” deep because of the limited focal sweet spot of the Glowforge, but if you physically move the lens down and lie to the Glowforge about the height of your material, it will happily do the job.

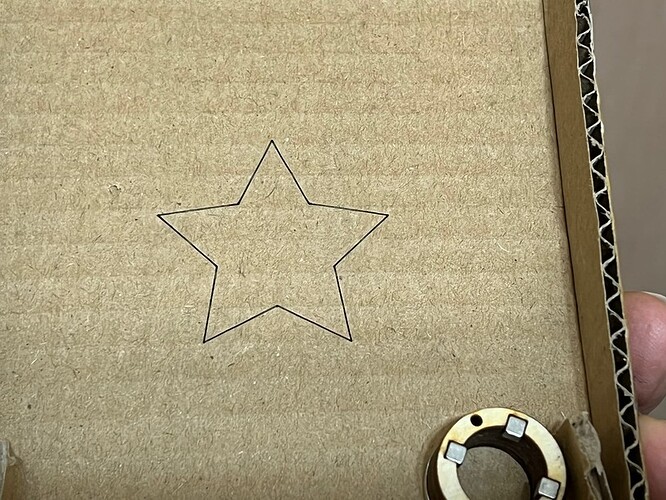

Here’s a quick makeshift “tray” that’s about 0.75" deep, a really shallow cardboard box bottom. The spacer can be seen in the tray, and I scored a star in the tray base at perfect focus.

There are two main caveats here.

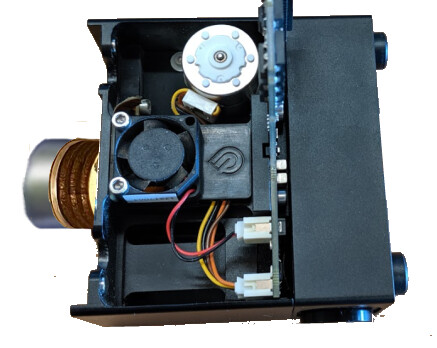

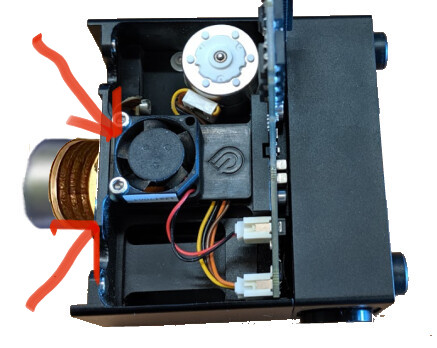

One is that you’ll be blocking the tiny fan that blows across the lens. I don’t know if that will have any real consequence, in theory it might mean that the lens will get dirtier than usual.

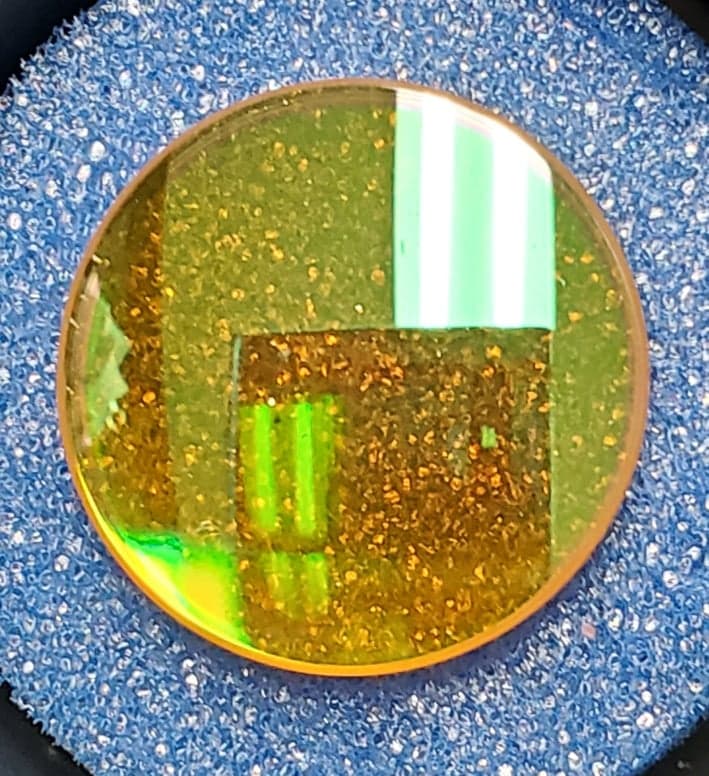

Two is that you really want this to be as light as possible, the lens height adjuster is probably not the strongest little assembly. This is three layers of BB with 4 tiny magnets to hold it inside the laser head and one lens remover tool magnet (you can see it on the bottom of the spacer) to hold the lens onto the new extender. I think this may be right on the limit of being too heavy – if I were really serious about this I might try 3d printing one, it would be far lighter than this prototype. I could also probably remove about 50% of the wood material just be redesigning it to have thinner walls. I was in a hurry and just wanted to finally get this idea off my chest.

This extender is about 0.47" tall, so it allows me to engrave the bottom of a tray up to about 0.97" deep.

In theory you could get more depth out of it, I did some back of the napkin math and came up with about 1.5" of play. I wouldn’t push that limit, if your lens assembly catches on your material bad things will happen.

Anyway If Glowforge would simply release a deep focus lens that focuses at the base of the Glowforge instead of tray height, this entire project wouldn’t be necessary. You could engrave the bottom of trays up to 2" or so tall at that point… but that idea was thrown into the hopper hole and we’ll probably never see it.

I feel better now, this one has been bugging me for a couple years. Thanks for reading and taking this idea off my brain.