I read the FAQ and it said that the Glowforge can cut delrin, which is primarily why I bought the laser in the first place but I’m having difficulty figuring out what settings to use since it doesn’t pull up under the materials list. How can I get 1/16 delrin cut on my Aura? Any help is appreciated thank you! Another question- will the Aura cut white delrin? I know white acrylic isn’t possible. Does the same thing hold true for white delrin?

Welcome to the community forum! ![]()

I was only able to find one video of someone laser cutting delrin with a diode laser with a quick search, and they did it with black delrin. White may indeed be a problem.

If you want to give it a try, looking at posts others have made about cutting delrin/acetal with their Performance Series lasers, they accomplished it with similar settings to acrylic, maybe a bit slower. So you might try starting with the Proofgrade cut settings for a similar thickness of acrylic. You can always hit print again to add more passes if it cuts part way through.

If you’re making no progress, white delrin with your Aura may be a no-go.

Thank you! That’s great advice. Thankfully I also bought black delrin and I’ll try that first. Fingers crossed. I might just need to return the white… my fault for not reading up and doing more research on the Aura series.

Hi @NewCrafter, welcome to the Glowforge forum!

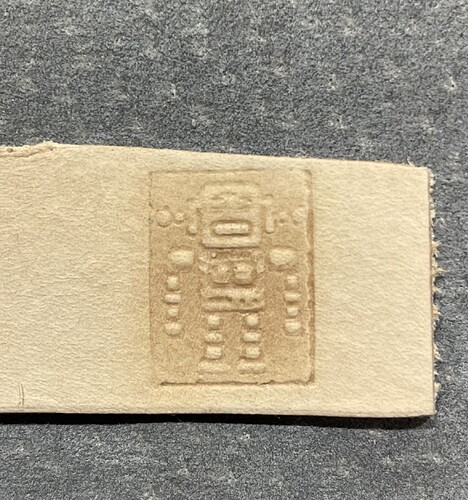

I replied to your question on Reddit but it’s difficult to upload photos there so I’m putting them here. The second photo is of leather that has been clamped to the Delrin for a couple minutes.

Here are the settings I used, for 1/16” black Delrin:

Engraving: full power (10), speed 50, 135 LPI.

Cutting: it didn’t go through with 4 passes at full power and speed 20, but you might be able to get through with more passes. The problem with Delrin is that it’s very melty and wants to re-solidify in the gap.

This was just a quick and dirty—you will want to experiment with settings to optimize for your use case. By the way, this is a tiny piece—about 12-15 mm tall.

You’re the best! Thank you for running tests and helping me out! I really appreciate it. I bought $120 worth of delrin I might have to return.

The laser could also be used to lay a pattern on a material to cut with a coping saw.

New owner (2 days!) here. I can confirm white delrin is like diamond on the Aura. Not sure where I read it now, but I swear I read that the type of laser on the Aura just passes through clear delrin and bounces off of white. I’ve got some black on order (1/16") and I’m hoping I can figure out how to get some clean cuts on that. It was one of the main reasons I bought the Aura. My son’s robotics team (VEX) is limited on what kinds of plastic they can use on their robot. And, of the two options, the delrin is a lot stronger. If anyone has actually cut black 1/16 delrin on an Aura, I’d love to hear about it. If I can’t figure it out we’ll be using this expensive machine mainly to prototype pieces before taking them out to get cut. Not bad, but not what I bought it for. Thanks!

I haven’t used Delrin on the Aura, but a few notes:

- The laser definitely goes through clear and bounces off white plastics

- You might have some success with multiple cutlines that are next to each other, so the delrin can’t flow between them - like instead of a square, concentric squares about 0.005 inches apart

- You also could engrave (very slowly!) a thick square, for the same reason

That last one is a technique I use sometimes to get through material where the kerf gets clogged, like thick woods etc.

Good luck!

@jhuggins1 , please see my reply above where I cut 1/16” black Delrin. It was not a clean cut, but it may give you a starting point for your testing.

I’ll give it a shot tonight, thanks. I’m kind of bummed that it looks like it won’t be a clean cut. I should have done more research, but I feel like it also shouldn’t be on the list of “approved materials” if it doesn’t work that well at all.

That’s not an ![]() limitation, that’s a feature of Delrin. It melts at high heat, so if you cut it with a laser…

limitation, that’s a feature of Delrin. It melts at high heat, so if you cut it with a laser…

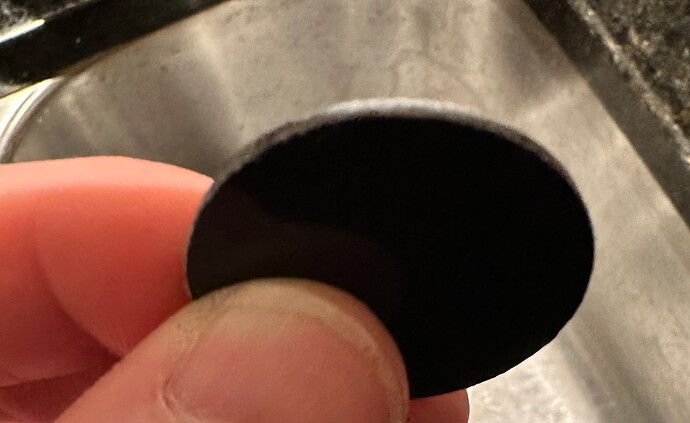

The black delrin came out the other side better than I thought it would. A quick (less than 30 seconds) sand and the edges were nice and smooth… Which is great! On the other hand, very slow. Which is…okay? Power 10, speed 50. This took 50 passes, which for this small piece was a little over 20. minutes. I’ll experiment more with speed to see if that can be lowered at all. But it might be a wash if it’s fewer passes, but more time for each pass. The robotics team will just have to know to build the time into their plans. We can still prototype in a couple of minutes with card stock.

(also—my cuticles aren’t great, but that’s unrelated to the GF…)

That’s great news! If you look closely at my photo above, you can see outlines of other cuts in that 1/16” Delrin. Those were made in my Glowforge Pro, and may indicate that the more powerful laser gives you cleaner edges. I will say, however, that the edges were not nearly as clean as when I cut other more rigid materials (like wood and acrylic).

I’d love to have a 40W vs. a 6W, but this was already a stretch of the budget. We’ve cut delrin at a nearby library (they have a robust professional cutter) and it’s like cutting butter. Fast and smooth. And thanks!