If the laser can score the glass deep enough, it doesn’t have to be straight lines.

Yes, exactly as shown in the video Joe posted. I’ve cut many a straight line (with assistance from a straight rule), and circles with a circle cutter. But my hand isn’t steady enough for nice curves.

I wonder how the Glowforge will be in my stained glass project, such as scoring designs?

Rod

I bet it would also look really cool if you etched off the backing on a mirrored piece of glass.

In terms of what you can cut in glass with a score line, it’s just about any shape accept for inside angles or really tight inside curves. Meaning you can’t cut pac man out of a circle of glass. The break wouldn’t stop at the inside point, it would continue through make his jaw fall off.

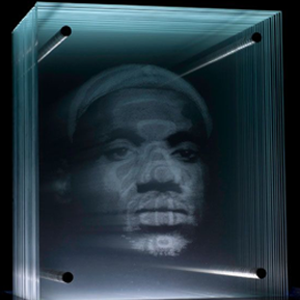

Not mirrors but still very cool. Search for layered glass art.

It does look really cool ![]() (working on a writeup with pictures, still playing with how to engrave the glass for scoring)

(working on a writeup with pictures, still playing with how to engrave the glass for scoring)

Oh wow, this is wild, we need to try this.

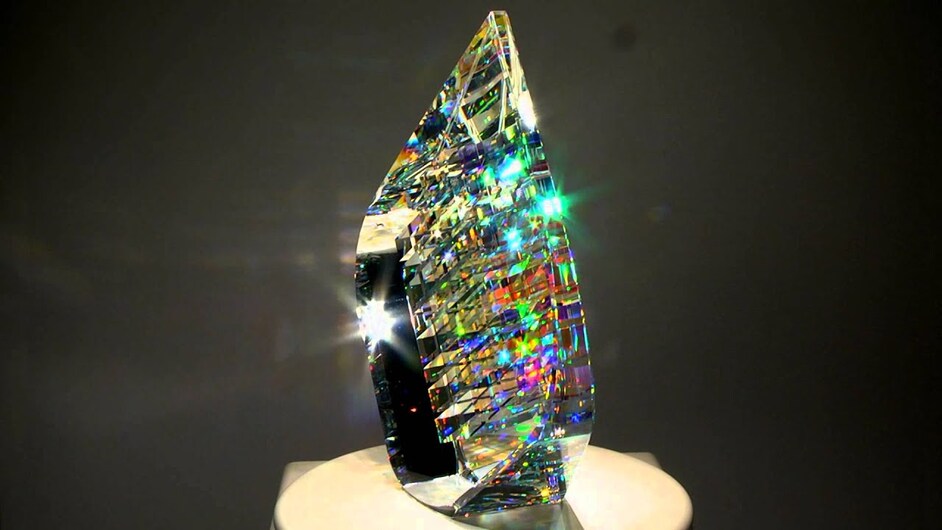

And then there is Jack Storms use of optical glass. Not really Glowforge relevant that I can discern at the moment, but still an amazing technique. Who needs diamonds when you have sculptures like this:

That is super cool! I was actually trying to describe doing it on one sheet of glass. These were the best examples I could find since the last time I had access to a sandblaster was before smart phones so I don’t have any pictures.

http://www.janetzambai.net/sandblasting_000.htm

It is a lot easier than you’d think it is, the hardest part is not cutting all the way through the glass by accident.

I will be waiting eagerly for that post, and I’d be happy to chat if you guys have stained glass questions in general, I’ve been doing it for about 15+ years.

It’s going to depend on the type of glass to some extent. Soda-lime glass (window glass) will probably respond better than lead crystal–the lead retains heat and can extend the fracture from the laser, which can distort the resolution. Borosilicate glass (lab glass or very old Pryex), would might hold up better, not sure.

I’m a glass sculptor (by avocation–) and one of the reasons I’m buying a Glowforge is for testing this kinda stuff.

One thing I’d like to test right off is the Glowforge ability to make very fine cuts in sandblast mask. I’d like to be able to cover a glass block with mask material, then have the GF cut the stencil directly on the piece. Anyone try this yet?

Two potential concerns: 1) partially melting the mask and adhesive so that they distort and/or are difficult to remove and 2) the kerf of the GF being too wide. On the latter: Typically, I cut the ask with an Xacto knife and the pieces butt up against each other. With the GF, how big will the gap be between pieces once the cut is made?

Thanks if anyone knows this…

On your second concern, the kerf for the Glowforge should be between 0.008” - 0.025”, according to the FAQ. From a quick google search, it appears a #2 Xacto knife has a 0.020" blade thickness. So I don’t think the kerf should be that much of a concern, but it might require some experimentation.

I have vector etched sheet glass from cheap picture frames (very thin), and it is not something you want to run your fingers over. Brandon_R summed it nicely with “heat or stress fractures”. It basically shatters the top of the glass, but so finely that it stays in place, mostly. little bits can poke out, and can snag skin (very tiny bits, but glass still cuts no matter the size, as any glass artists knows ;p )

As for vector etching to get a score line, my inclination is to say that the way that it shatters the top of the cut would not make a very clean break. I made a layered sheet glass piece, and one piece magically imploded itself one day, so I surmise that there may be stress left in the glass from the extreme heat the laser produces.

I do stained glass and am learning to use a kiln now… I can see the GF making some of my cuts less frustrating and also be able to add pattern effects to cut pieces. Art glass tends to be thicker than picture glass, and if it is designed for kiln work (think BullsEye glass) it mY etch and cut. I sure will be experimenting once I get my GF! Check out my website for the work I have done so far. Www.ArrietaGlassworks.com

I also do stained glass and I hope I will be able to score patterns onto the glass. Can’t wait to try.

That is awesome! Looks really cool

can’t wait to try this