I have been working with some 2 and 3 layer acrylic ordered from B.F. Plastics. The brand is Duets Laser XT.

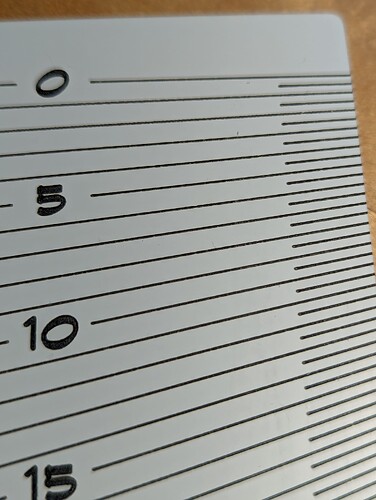

This consists of a very think layer of one color bonded to a thicker layer of contrasting color. You can burn off the thin layer creating a nice contrast. Product comes in 1/8", 1/16" and 1/32" thickness and wide variety of color. The 1/8" thick size comes in 3 layers so you can print on both sides. The 1/32" is very flexible and has created some nice custom rulers.

I am working to create some signs and an angle gauge (think ruler) where I need crisp thin lines and clear text. The jury is still out on durability, the top layer is very thin and I fear it will scratch or wear off. For signs this is great, but for a measuring tool that will be handled and abused I am not sure how the thin layer will hold up.

Here is what I have learned about using this product:

Remove the Protective layer

I have found the protective layer tends to melt onto the edges of the letters and you can feel a ridge and it does not look clean. In addition it appears that some of the material remains on the letter creating what looks like white spots.

Clean with Isopropyl Alcohol

The cut edges feel a bit sticky and there is some staining down wind of the cut. These clean up very fast with some Isopropyl Alcohol.

Run score likes past cut edge

I noticed a very rough edge where the score lines met the cut line. Some light passes with sandpaper cleaned that up. I had much better luck by running the sore lines past the cut edge a few mm. Now that I type this, I suspect the problem might have been that the protective film was left on during this test.

Engraving Settings

Speed: 545

Power: 40%

LPI: 340

Passes: 1

Any faster and it seems like the edges are jagged as the laser power up and power down is not instantaneous. Lettering seems less dark with lower LPI.

Score Settings

Speed: 500

Power: 35

Passes: 1

Lower power and the line was not as dark. Higher power did make a deeper cut, but did not seem to improve line quality. Too high and it seems like we are deforming the edges.

Cut Settings

This is just acrylic. Use whatever settings you use for the thickness.

To the left of the line the protective film was left in place, to the right is was removed. Without the protective film the edges seem crisper and lettering darker.

Staining downwind of the cut cleans up quickly with Isopropyl Alcohol.

I am pretty happy with the quality of the lines and lettering. Time will tell how durable it is.

The 1/16" thick size fits perfectly in the label bracket of my tool chest. This makes for a more durable label than other options I have tried. (Now that I look at it, I can tell this was created with the protective layer in place).