Per Dan: “WARNING: Advice in this section is unsupported and is not reviewed by Glowforge. Following it may void your warranty, damage your machine, and cause injury or death.”

Okay. Don’t do this. It will end badly on multiple levels. The 2022 AirPods case looks and feels like the kind of plastic that releases toxic and corrosive fumes, whilst turning into a gooey mess. Best to leave it to Apple’s free ‘engraving’ service.

So,… anyhow,… this is what I did:

First I found a sacrificial Apple power adapter to allow me to home in on appropriate settings with similar material before going ‘live’ and risking a $250 holiday present. Poor, poor, sad little power adapter, it did nothing to deserve this, but hey, science! With viable settings in hand, I proceeded to the real deal.

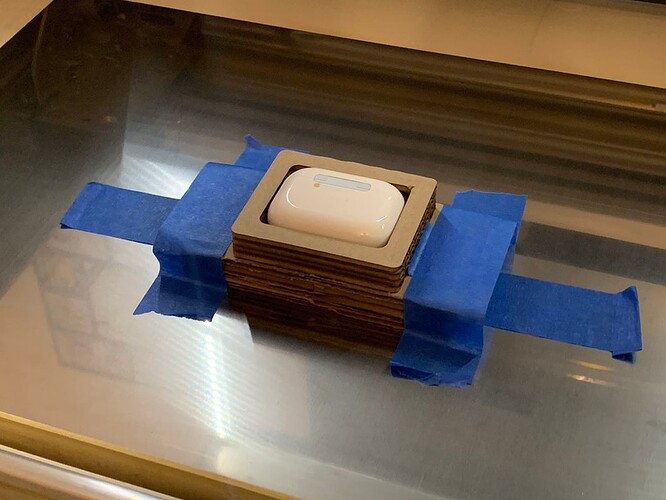

Used some cardboard to make a jig to hold the case. The case is too thick to sit on the tray, so I stacked five layers (laminated with wood glue) to get the surface of the AirPods case above 40mm from the bottom of the chamber and back into the focus range of the beam:

BTW, I like my settings for cutting cardboard better than GF’s. Mine are more reliable and creates less ash. Cardboard cut settings: Speed = 300, Power = 60, Passes = 2

Converted the artwork to a 600 dpi png file, to force the GFUI to treat it as an engraving. Image was strictly B&W, as the plastic’s reaction is very non-linear.

GF engrave setting for 2022 AirPods case:

Speed = 1000

Power = 40

Grayscale = “Vary power”

Min Power = 0

Margin optimization = “Maximize quality”

Lines per cm = 535

Passes = 1

Focus height = “Auto”

The resulting engrave depth is very close to what you would get with acrylic, making that a safer haven to experiment with the artwork. Also note my GF was among the first units shipped, aka ‘old’, so my power settings may not line up with a fresher laser tube.

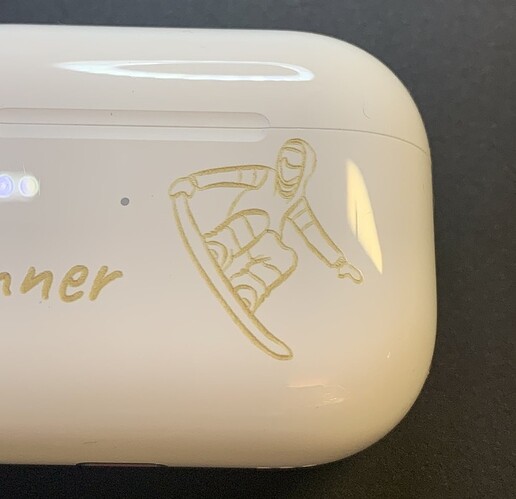

The who-knows-what plastic Apple is using for this year’s AirPods turns to ash and gas, but the engraved surface is relatively smooth with high dpi settings. After cleaning with a 70% isopropyl wipe the engraved surface looks similar to gold paint:

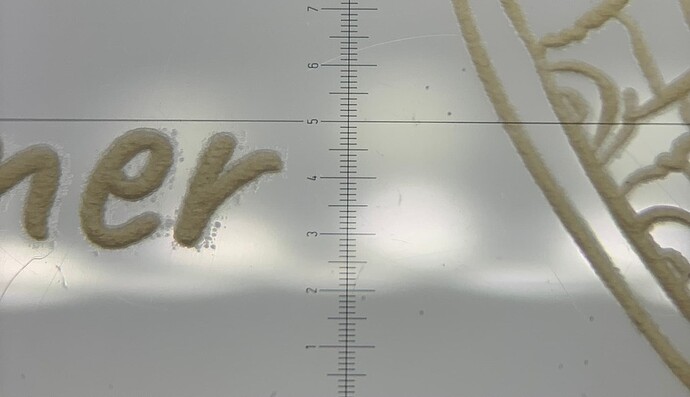

I engraved without any surface protection layer, but after looking under the microscope I have some regrets:

There does appear to be some splatter damage, but fortunately it’s not really noticeable unless you’re looking for it. If I were to do this again, I’d use TransferRite (or similar) and bump the power up to 50.

I investigated infilling the engraved area with paint, but the engrave depth is pretty shallow, making it difficult to keep the paint corralled in. I’m reluctant to engrave any deeper and further unleash whatever demons hide within Apple’s plastic brew. Silkscreen-like techniques work with the shallow engrave depth, but the plastic Apple uses will show scratch marks from the slightest insult and will not forgive any attempts to clean up overspill. I’m just gonna be happy with the faux-gold look.