I’m reporting back with regard to engraving on stainless steel with mustard! It really engraves into the metal!

Disclaimer: maybe you all already figured this out, but I’ve been reading for years that CO2 lasers can’t “touch” metal - not even aluminum foil. But with some sort of third-party aftermarket coating (Cermark, LBT 100, Dry Molybdenum Lube, and even Yellow Table Mustard, et cetera) one could engrave through the applied coating and end up with an embossed back, raised “mark” on the metal.

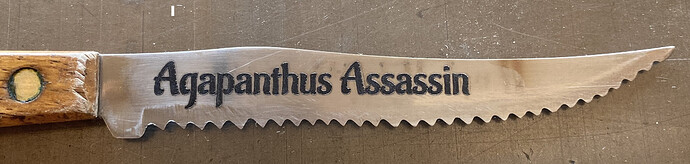

Well, back in Jun2021 I applied Yellow Table Mustard (it deserves capitalization because it works and is far cheaper that the other coatings) to the stainless steel blade of a an old serrated kitchen knife. Perhaps you can figure out from the pics the blade’s purpose. The engraving worked “as advertised” living a slightly raised “embossed” black substance. Would it hold up to intense removal of the invading Agapanthus plants? Yes (and no). While using my Agapanthus Assassin blade the other day I realized that the black embossed substance had been abraded to the point that is was no longer in/on the blade. But what was left behind was real, genuine engraving into the stainless steel! The engraved metal was gone — the engraved lettering was eaten into the steel! Isn’t this worth investigating further? I think so and challenge the engineers in our midst to explore further this phenomenon.

And you will no doubt notice that I repeatedly resharpened the blade to maintain its Assassin certification. That has nothing to do with the engraving process but explains somewhat the differences in the pics…