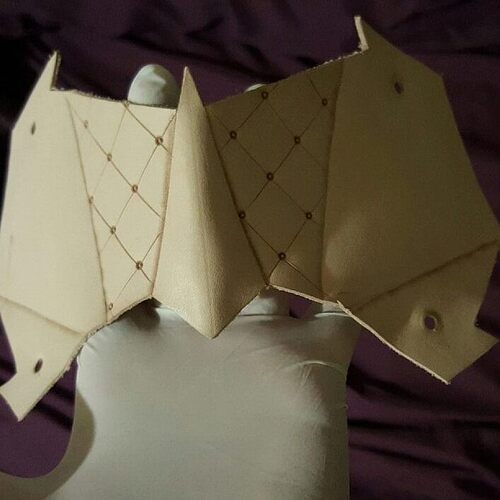

I just think about the DAYS/Weeks tooling all this leather usually takes me. I have people always asking for patterns/templates and recreating each piece exactly is almost impossible. Can’t wait to show this thing off at my next convention panel!

Those look really great! I’ve never done anything in leather on a laser-cutter, and I’m really looking forward to trying it. I’ll have to find a local leather shop.

Great work, and I can’t wait to see what you produce in the future.

It’s not too difficult if you can draw or design. I’d suggest a Tandy Leather if there’s one near you. They’ll give you a good hint on things like what kind of leather you can use for whatever project you have in mind. I’m curious if different finishes/oils can help with the laser though. Because I feel the laser may dry out the leather and compromise a bit of the durability. Can’t wait to experiment though! I make some simple earrings which I’m sure wouldn’t be an issue with a laser cutter ![]()

In my limited experience, the laser (or wood burning tool) doesn’t dry the leather too much. Typically you would condition the leather before you apply any finishes and that usually adds the moisture back in.

Your work is beautiful. Please keep in touch so we can see how you will use the GF to enhance your work.

I actually wanted to try and do the laser cutting after applying the conditioner/finish. Just because most of moisture would be sealed already and when leather tends to get branded it’s usually afterwards. A waxy finish like like saddle lac I feel would help with it making it a bit more dense and all. Also makes me curious of the results of using the laser while it’s being wet formed.

Will do, love seeing everyone brainstorming away getting new ideas. I can’t wait to implement them and make some crazy templates that are seemingly impossible free-handing!

That is truly amazing stuff @hybridemblem. It’s much harder to laser finished leather, but vegetable tanned leather lasers well before finishing and I haven’t had any problems with durability post-.

I have to say, props and armor is a major reason why I decided to get a GF. I have not done much so far, but hope it will help me do some. Your armor is definitely an inspiration, and I hope stuff I make comes out even half as good. Keep up the amazing work. And do you have any more of your work up anywhere? I would be really interested in seeing it.

Sure, I post most of my work on Facebook. I have big project I’m doing atm so I should be posting some progress pictures soon.

Interesting, because that’s exactly what I’m wondering. Also, will the sticky sheets used for the acrylic be in a size bigger than 8 1/2" x 11"? Wondering for those of us with larger scale printers. Can’t wait to see the Pro in action for those longer projects. Should make crafting belts a lot more fun since I don’t have to be limited to a continuous design from a smaller seamless pattern.

Are you talking about the pre-masked acrylic sheets that will eventually be available from Glowforge? Because those should be available in a 12x20 size. The “sticky sheet” is a mask that will contain invisible product identification information for the glowforge to read, as well as protecting the material. You can use masking tape (transfer tape, application tape) for protecting your own materials, but it won’t have the invisible ID info.

If your large/wide/grand-format printer can print on paper, you should be able to find a way to lay those designs onto material to put in the Glowforge… just don’t use vinyl!

Yes! Those exactly, couldn’t think of what they were called at all. Very helpful! Then again if I have the file I assume there’s not much need to print unless I want to add extra things by hand. Thanks again!

I wonder if this 3M repositionable spray mount is laser safe?

http://amzn.to/1Wj05Mz

The MSDS is not TOO scary…

http://multimedia.3m.com/mws/mediawebserver?mwsId=SSSSSuUn_zu8l00xl8m15xm9ov70k17zHvu9lxtD7SSSSSS--

Oh man, I dont know how I missed this thread. I must have been out of the country. Its awesome to see another prop maker on the forums! Your stuff looks great. I tried to hit the link you posted to your facebook page but it seems to be broken. Are you still around on the forums?