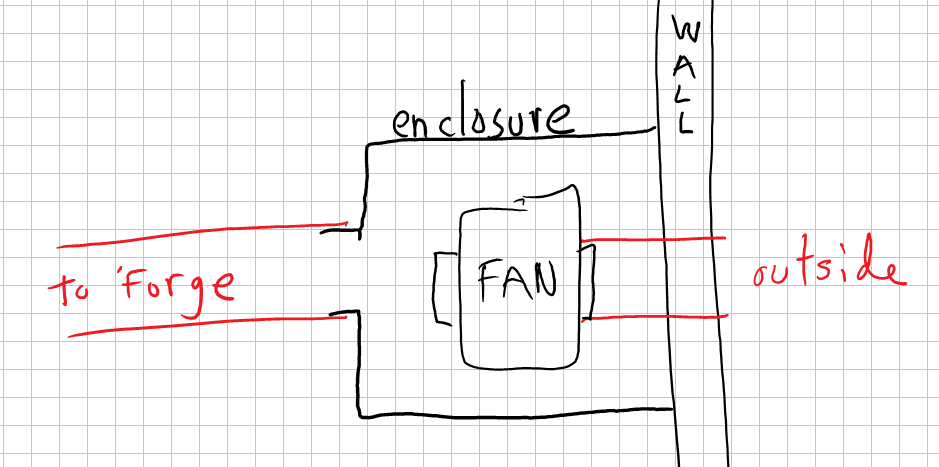

I think I’ve posted this idea before, but the only way I can think of to make the entire exhaust run act in suction, while keeping the fan indoors, is to build an enclosure at the end that contains the fan. A little more work, but then no need to make airtight duct connections/seams nor seal the fan housing.

The enclosure has to be strong enough not to collapse under the vacuum produced inside it. An added benefit is that the enclosure acts as a noise barrier for the fan.