Here is my new Cloudline AC Infinity 6" external exhaust fan. I like it. It’s much quieter and the noise there is is not as high pitched. It works great at keeping the smells out of the room. I did about three hours of acrylic cutting Saturday evening and it went well.

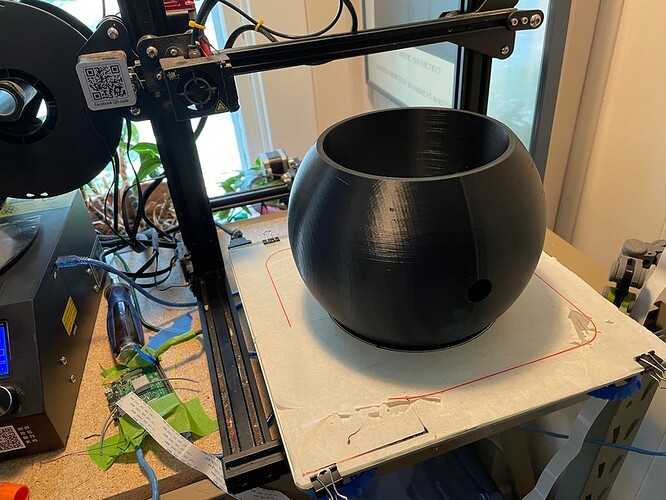

I went with 3D printed tubes and blast gate. Just PLA since I’m not set up for ABS and other higher temp filaments. This will do until I can start using these more robust filaments.

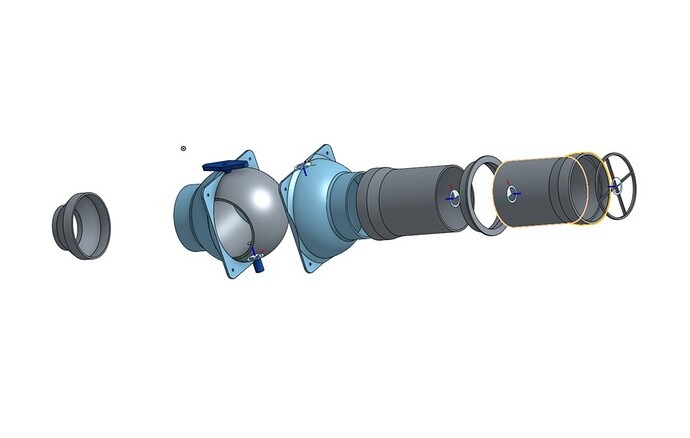

It was interesting figuring out the geometry needed for the ball in the valve. I am sure there are formulas to automatically adjust for size in relation to diameter of the tube. But I just played with the geometry until it looked right. I don’t know how to do booleans with parts yet. Something I need to learn which would be what is needed for this.

This was the longest successful 3D print I have every done. After three or four false starts, one of which was trying to switch filaments mid job, I managed to get the whole thing printed. 30 hours. The Creality did a good job. It’s nice to have a bigger printer for something like this. This is where getting bigger nozzles and more robust hot ends comes in handy, but I just have the stock .4 mm.

On assembly everything fit perfectly. Just a light sanding of the inside of the valve casing and the outside of the valve to get some pimples off.

Learned a few things in Onshape for this project. I’m not quite sure how to terminate the outside tube. I’ve been thinking of mesh to keep the bugs out, but don’t want to block the flow. Then I have to think of bigger things like bats, squirrels, or birds. The ball valve blocks well, but there is a good bit sticking out that could get rain, etc. Maybe a simple flap would be best with a traditional angled cover over it.

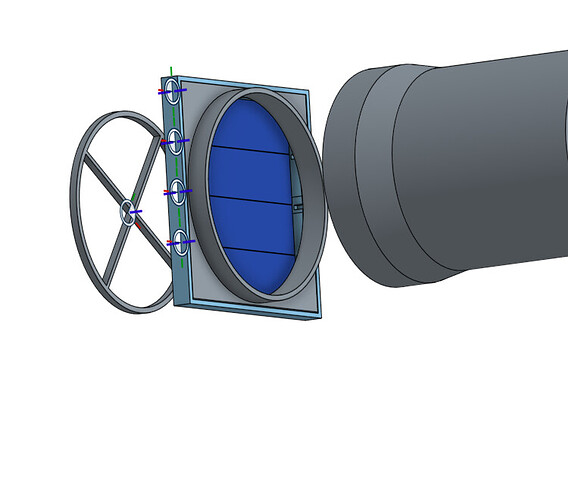

Edit 9/21/21. Here are the flaps. A simple frame and four flaps. Hinge pin made of coat hanger and attached with Gorilla tape.

The servo is coming today. It will be my first time messing with servos. I’m familiar enough with micro controllers and stepper motors, but this particular application outside of a CNC setup is new territory. I’ll post an update when I get that working.

I’m thinking about automations in Home Assistant. It is easy enough just to control with a button push from my phone, but remembering to open the valve and turn on the fan before pressing the white button is essential until then. I have to find the original Glowforge escutcheon reminding me to connect the exhaust. Right now I am escutcheonless.

This is quite an upgrade. It’s a bit big and colorful, but gets the job done.

Got the servo working. Thanks for the help @bwente . Printing a case for the microcontroller now. I am trying to figure out the code to get the valve to go a bit slower. Problem is that I’m using ESPHome integration for Home Assistant and the servo library isn’t ready for ESP32s. I’m fumbling around in the dark since I have little experience with this coding, but it works just fine. Just a bit fast and it might jerk the fasteners out.

I’ll post some more pics when I do the final assembly and seal the exhaust runs with silicone. But here is the valve in action.

it worked for a while and then became blocked and the smoke wasn’t clearing. I use one of those dryer vent things now and it’s been perfect.

it worked for a while and then became blocked and the smoke wasn’t clearing. I use one of those dryer vent things now and it’s been perfect.