https://www.protohaven.org/proto-shield/

Let me know how the .06 works out… Isnt that what the spec call for? Can’t recall…

https://www.protohaven.org/proto-shield/

Let me know how the .06 works out… Isnt that what the spec call for? Can’t recall…

For all those planning this:

The face shield material itself is supposed to be .020" PETG (.5mm), while the headband material is the aforementioned .060 PETG. The headband must be more rigid, but the shield itself must be flexible enough to be bent by these headbands.

I made a few of these for friends and added a top shield.

I would like any feedback from the med field as to if this is sufficient.

Also I am in the Rochester buffalo area of NY and can produce these in quantity if anybody is in need.

wow thats great. What material did you use and more importantly where did you get it? I have the .06 petg but cant find the .020 stuff

Thanks, I have a few more changes I want to make too, the shield seems a little narrow.

It’s actually material I had, I have a huge roll of it, the only label is inside the tube and it says PTE. We got it years ago when we bought out a model shop. I checked it for chlorine and it’s good there. Cuts great. Has the feel of polycarbonate. It’s about .020” thick. It has a little haze to it but not bad. I would be willing to ship some to you if you think you can use it.

Can I have the AI file please?

Tom, I am in Buffalo but a newbie…LOL. Would love to connect for some guidance. fantasticfriendswny@gmail.com

Sure. Give me a little while

I’m all set. Thanks. But if you could share a picture or assembly that would be great. Thanks!

What settings do you use to cut this? I have been cutting this and the heating process makes the material too brittle to bend. Am I doing something wrong?

Will this work on a glowforge plus?

What material are you using?

I have the plus as well. I have not cut any PETG, just acrylic. Acrylic is too brittle for this face shield design.

Nice work there. How long was your cut time? per shield?

PETG 0.06" clear

I would really love a version of this design that works with the Glowforge Plus. The bed dimensions are 20.5" x 13"

Also I have no clue what settings to use with .030mm polycarbonate - hints please? My goal is to mass produce these to assist front liners - We are not doing it for profit in any way.

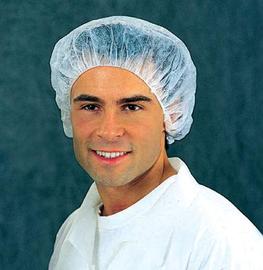

i think they can just use polyproyline bouffant caps.

Doesn’t do anything to protect the eyes.

Polycarbonate (aka Lexan) doesn’t really cut well via laser without very high power & speed. It tends to melt and burn. Thin (like membrane thin) works okay but I’m not sure how 0.030" will cut since it’s not really that thick but thicker than anything I’ve bothered to use polcycarbonate for. You’ll want to run some cut tests before committing to using it for a lot of production.

I’ve never handled that so I’m afraid I can’t be of much help