is that enough empirical data for you, I have 40 more pictures of 40 separate machines I can post

Glowforge finally admitted there was a fault and are putting sleeves on NEW MACHINES ONLY

(no refurbished ones)

I trust you, nice sleuthing.

But no way am I going to facebook, I know a trap when I see one lol

if I wanted to install some sort of padding or tape to shield it myself, where is the friction point in an intact machine?

I partnered with a company that makes ‘sleeves’ you can get the stuff yourself off amazon for $10

Wait, so then what is included with the $89 price on that item if I have to buy the sleeve on amazon?

Considering how simple this concept is, I’ll probably just go looking for that red wire and see where it might be rubbing, this can’t be hard to figure out. Duct tape on the offending surface or around the wire will probably give it plenty of protection, and can be easily replaced if it starts to look bad.

you don’t want something with glue and that can catch on fire,

don’t be cheap on an indoor BBQ.

I’m sure I can work it out.

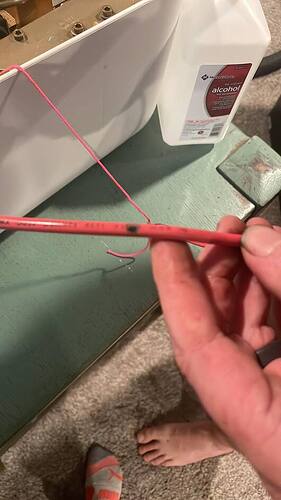

That’s an insulation failure. Either the wire inside is breaking and arcing or the wire is routed close enough to some grounded object and the insulation is defective and the wire is arcing through the insulation.

Based on my experience with this type of failure I would be looking at two things:

- Check the bend radius of the cable at the failure point. If it is too small the stranded wire will fatigue and break, strand by strand. Over time as more strands break the current will arc between broken ends and burn the insulation. If This is the issue, the sleeve will only help for a while. I suspect we would see it in a lot more than 40 cases, though I would be very curious to know how many hours on average the machines had that experienced this failure.

- Enforce a lot of air space and put more insulation between the wire and the ground point. I would probably use neoprene foam or something along those lines. Again, the sleeve is a bare minimum fix for this issue.

Bingo. I hadn’t considered the wires arcing and burning from the inside. There’s no real sign of abrasion in the pics where it was just starting.

Yeah, some of these machines have been put through the mill.

Hi @Deleted,

Thanks for the heads-up Jon! Now, if I just knew which side of the machine I could find it on…

You know what, I think you’re right. There’s no evidence of abrasion on the outside of the wire, I’d expect it to look like it had taken damage prior to the short.

A sleeve might help but seems like it would be only because it increases the rigidity of the wire and prevents tight bends.

Also, if this is a single conductor type of wire (it looks like it is, judging by shape and color), then short circuit can’t really happen with broken wires. Seems to be an insulation failure.

Someone needs to take taht wire apart and verify the number of conductors.

Didn’t see this answered, So was this problem that impacts a massive amount of machines found to promote the $90 set of instructions to fix it?

Seems odd this started out as it should be recalled ect then turned into here’s how to fix it if you pay $90.

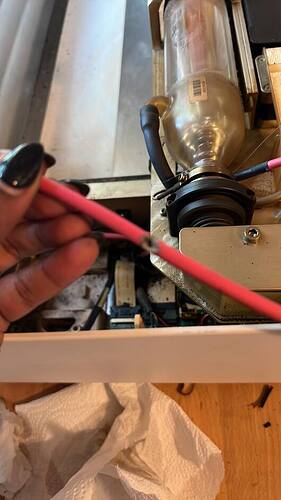

there are two things at play, If ignored, the high voltage cable will burn thru because of a factory defect, if you fix the cable NOW with the sleeve you correct the factory defect.

it happens at different places most common 10" just as it enters the gantry and 24" - the sleeve goes from the tip all the way to the top of the tractor

they used the cheapest POS cable so i think it has 6 maybe 8 wires

Still didn’t answer the question, but it is clear fear is the sales tactic. ![]()

![]()

WTF? I tell you where to get the supplies, GTFOH - its comments like that, that keeps me away from this place. – sorry I even offered help.

Sorry, I didn’t visit the FB group I tend to stay away from those. Just saw the link for $90 posted but also it was stated the supplies were $10, Just was asking why a $80 difference as it sounds like that is the cost of the instructions.

You more than anyone know that people don’t like to be monetized here – I’m not sure what reaction you expected to get.

I’m glad you posted your pics and let people know about the risk. The cause and solution aren’t quite as clear, but more info is good.

Care to show a cross-section of the cable? I would be really interested to see how many conductors they have.

I would think that if it were really the cheapest cable we would see a lot more of these failures. Based on the information provided so far, I am leaning toward an assembly issue that allows the cable to be routed where it shouldn’t be, rather than a material issue.

I think I have to agree with @evansd2; the cost of the components, even with the cost of developing the videos, seems extortionate, especially for the fact that if everything is really as bad as you have indicated, this is a temporary fix.

![Kramer the movie expert [Seinfeld S7E08] Moviephone](/uploads/db6859/original/3X/2/3/23836043d702d27eaf4390f30d39001e559b1d0a.jpeg)